Epoxy resin composition for casting molding, and electronic part and manufacturing method thereof

An epoxy resin and casting molding technology, which is applied in the field of epoxy resin compositions for casting molding, can solve problems such as capacitor capacity changes, failure to work normally, and cracks in the cured sealing resin to achieve reduced settlement and high insulation breakdown voltage , excellent effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

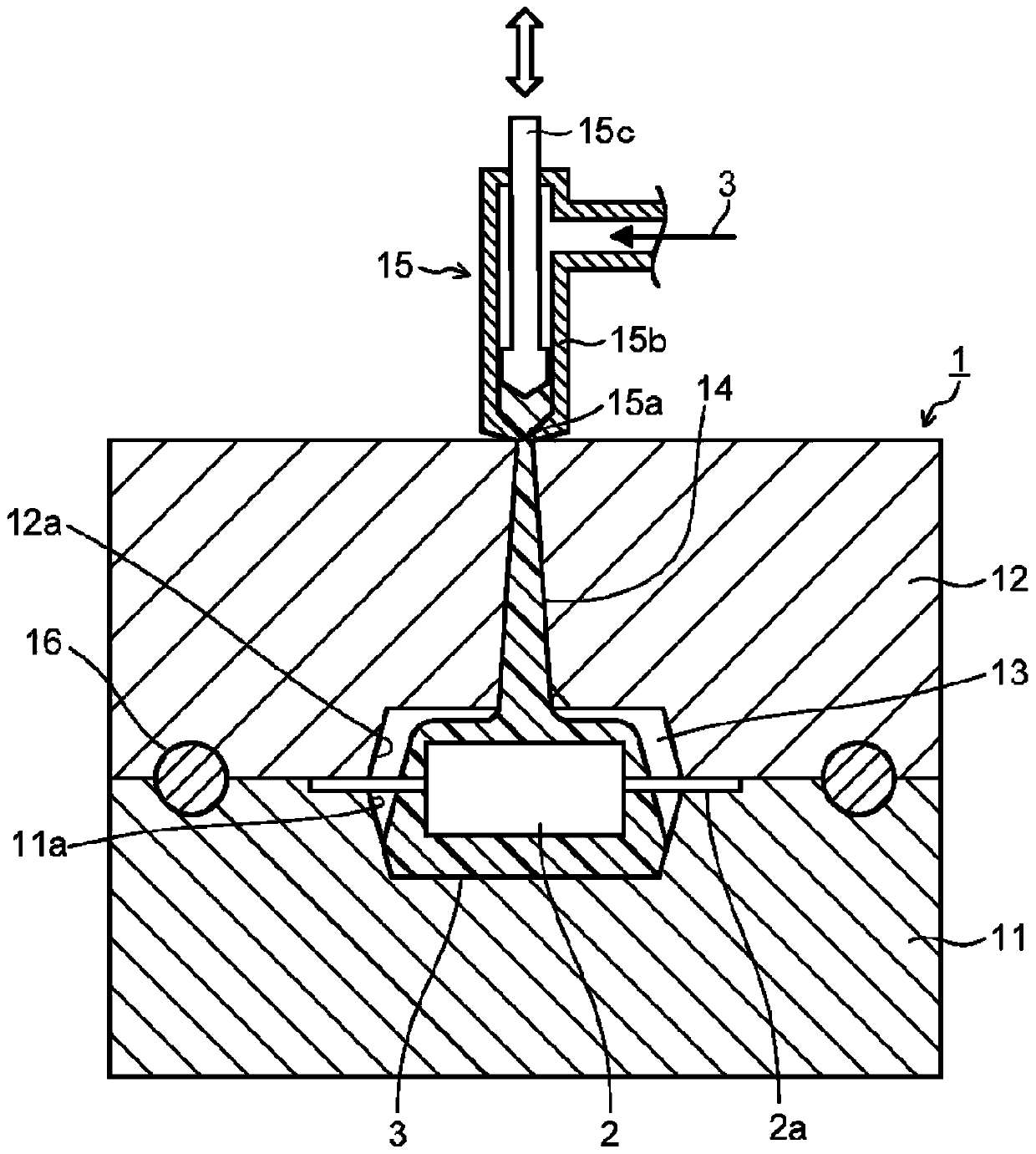

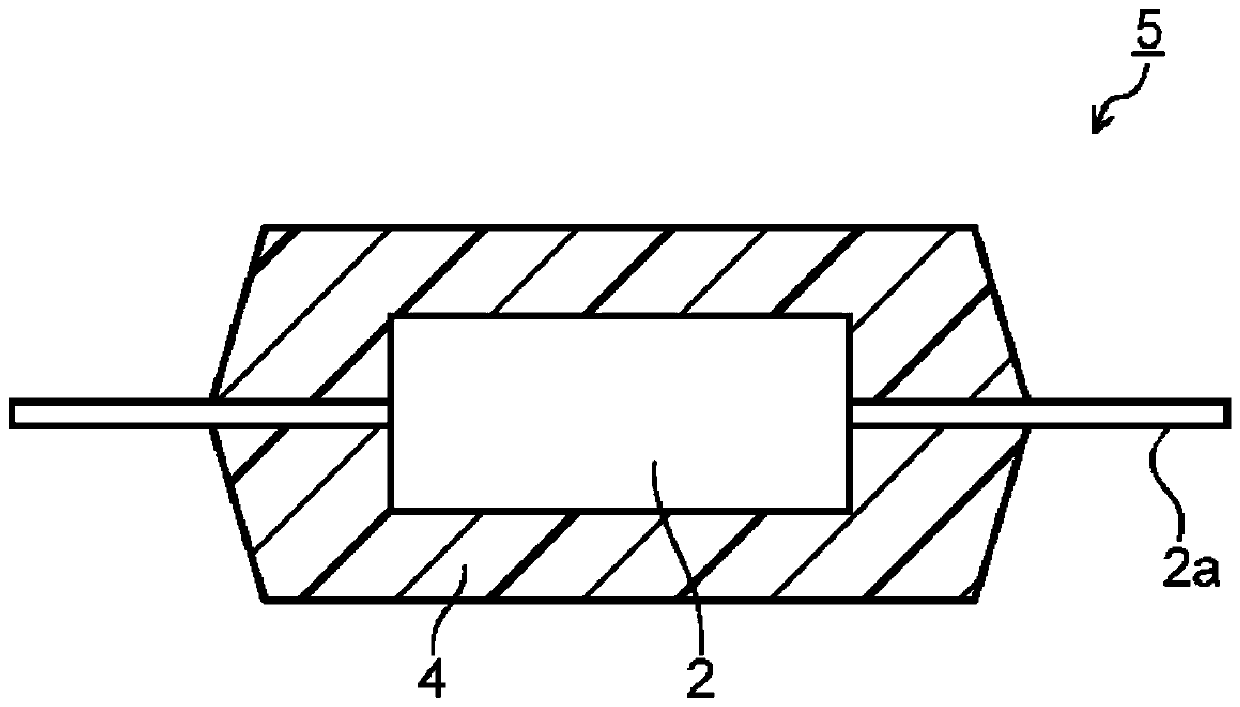

Image

Examples

Embodiment 1~8 and comparative example 1~7

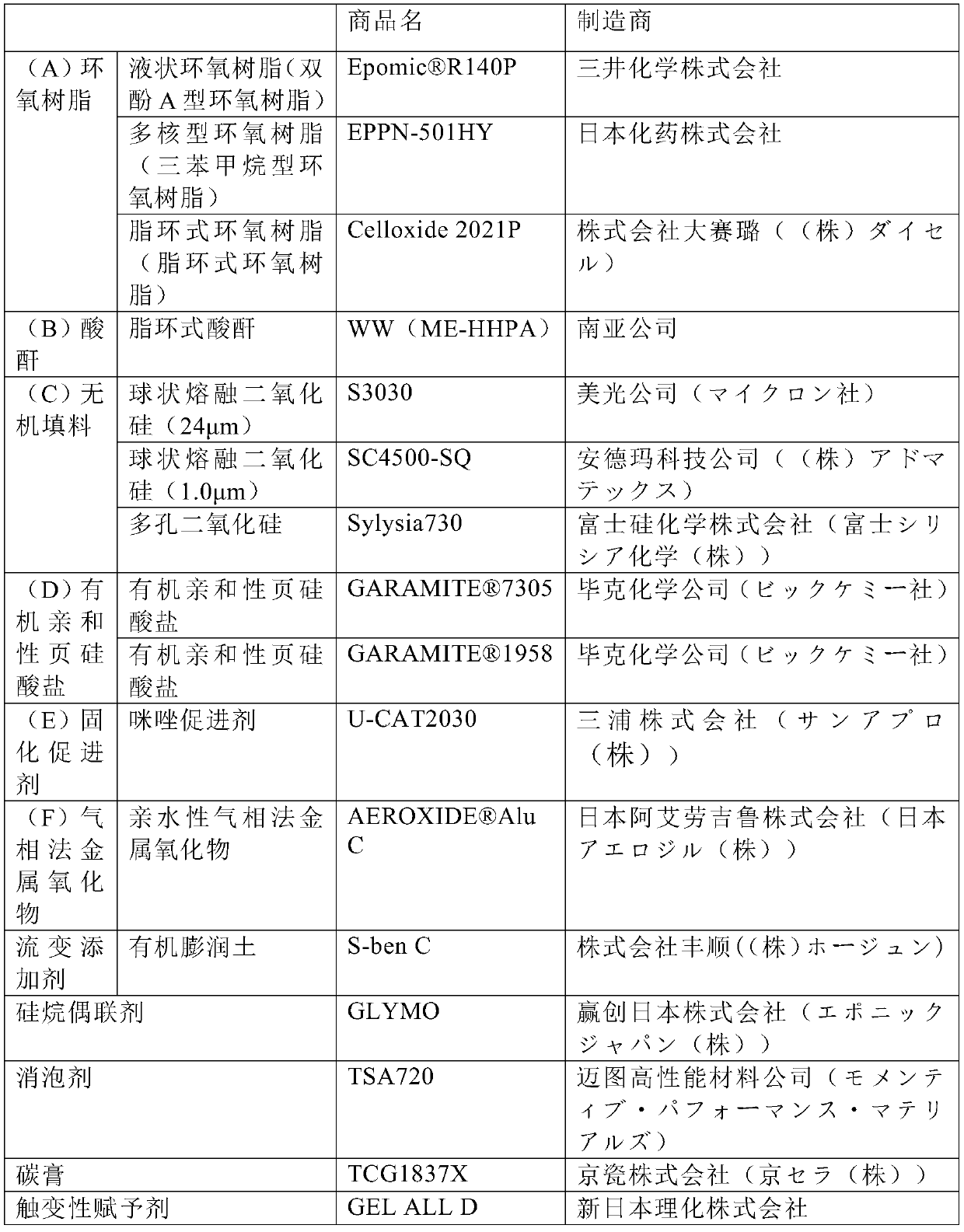

[0079] The types and compounding amounts of the components described in the first component column of Table 2 were put into a universal mixer heated to 100° C., and mixed under vacuum conditions for 1 hour to prepare the first component. Then, each component of the type and compounding amount described in the second component column of Table 2 was put into a universal mixer heated to 60° C., and mixed under vacuum conditions for 1 hour to prepare a second component. 100 parts by mass of the first component and 100 parts by mass of the second component were mixed using a universal mixer to prepare an epoxy resin composition for casting molding.

[0080] It should be noted that in Table 2, blank columns represent non-combination.

[0081] The characteristics of the epoxy resin compositions for casting molding and the characteristics of cured products produced in Examples 1 to 8 and Comparative Examples 1 to 7 were measured and evaluated under the measurement conditions shown bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com