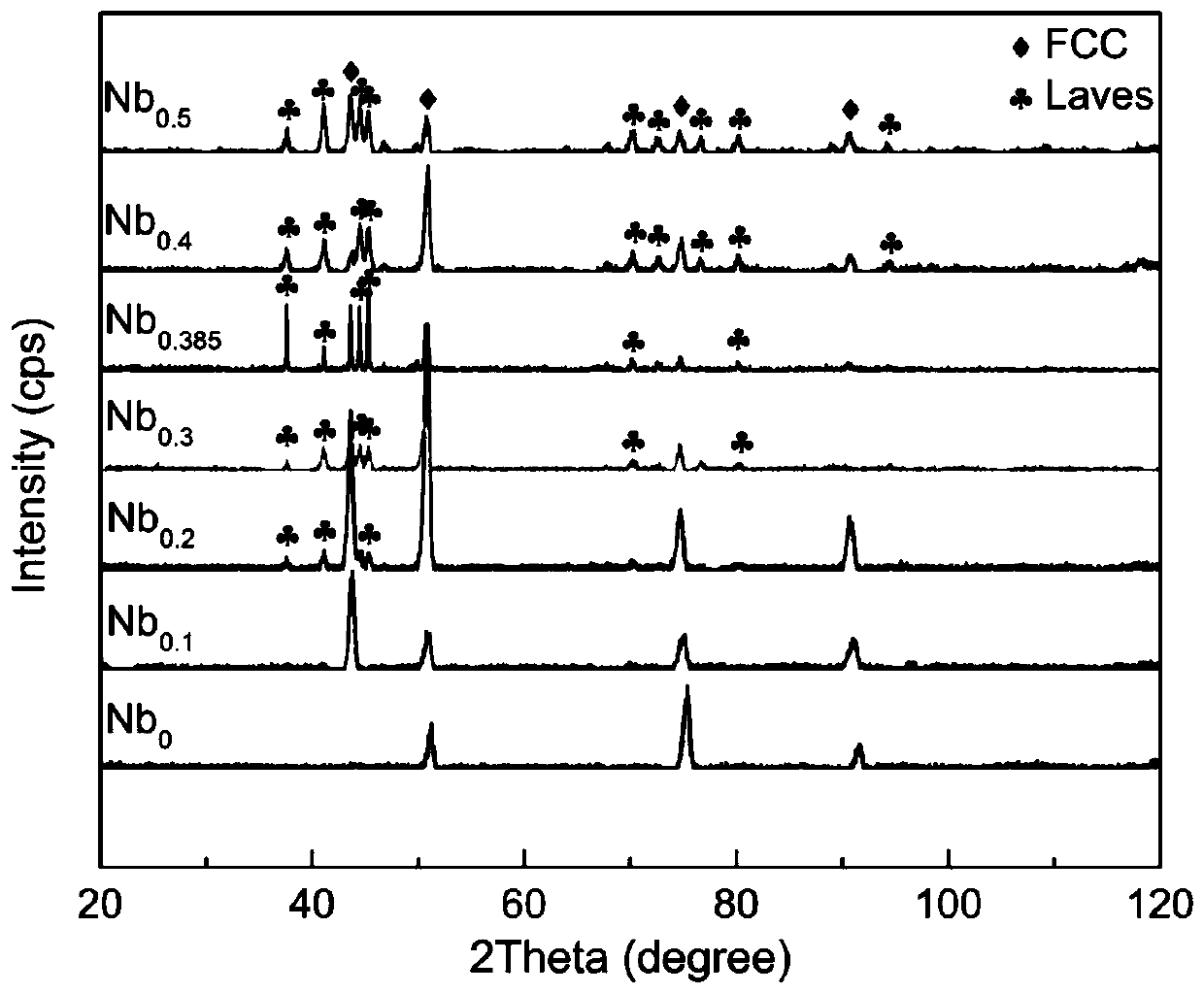

CoCrNiNbx eutectic intermediate entropy alloy and preparation method thereof

A technology of entropy alloys and metal raw materials, which is applied in the field of eutectic medium entropy alloys and its preparation, can solve the problems of insufficient strength, poor castability, poor strength and plasticity, etc., and achieve the effect of reducing defects such as slag inclusions and good sample quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1:

[0034] A CoCrNiNb 0.3 Eutectic medium entropy alloy, the content of its constituent elements Co, Cr, Ni, Nb is 1:1:1:0.3 according to the molar ratio, the specific preparation method is as follows:

[0035] Step 1, pretreatment of high-purity Co, Cr, Ni, Nb elemental metal raw materials. The purity of the high-purity Co block, Cr sheet, Ni block, and Nb sheet is not less than 99.95wt.%.

[0036]The specific method is as follows: grind the block Co, then put the Co block, Cr sheet, Ni block and Nb sheet into different beakers, pour a certain amount of absolute ethanol (just submerged the raw materials), and use Clean with an ultrasonic cleaner for 15 to 20 minutes to remove scale and impurities on the surface of raw materials. Then dry the cleaned raw materials with a blower at low temperature to obtain clean Co, Cr, Ni, Nb raw materials, which are put into clean sample bags for later use.

[0037] Step 2, weighing Co, Cr, Ni, Nb metal elemental raw mate...

Embodiment 2

[0046] A CoCrNiNb 0.385 Eutectic medium entropy alloy, the content of its constituent elements Co, Cr, Ni, and Nb is 1:1:1:0.385 according to the molar ratio. The specific preparation method is as follows:

[0047] Step 1, pretreatment of high-purity Co, Cr, Ni, Nb elemental metal raw materials. The purity of the high-purity Co block, Cr sheet, Ni block and Nb sheet is not less than 99.95wt.%.

[0048] The specific method is as follows: grind the block Co, then put the Co block, Cr sheet, Ni block and Nb sheet into different beakers, pour a certain amount of absolute ethanol (just submerged the raw materials), and use Clean with an ultrasonic cleaner for 15 to 20 minutes to remove scale and impurities on the surface of raw materials. Then dry the cleaned raw materials with a blower at low temperature to obtain clean Co, Cr, Ni, Nb raw materials, which are put into clean sample bags for later use.

[0049] Step 2, weighing Co, Cr, Ni, Nb metal elemental raw materials accordi...

Embodiment 3

[0058] A CoCrNiNb 0.5 Eutectic medium entropy alloy, the content of its constituent elements Co, Cr, Ni, and Nb is 1:1:1:0.5 according to the molar ratio, and the specific preparation method is as follows:

[0059] Step 1, pretreatment of high-purity Co, Cr, Ni, Nb elemental metal raw materials. The purity of the high-purity Co block, Cr sheet, Ni block and Nb sheet is not less than 99.95wt.%.

[0060] The specific method is as follows: grind the block Co, then put the Co block, Cr sheet, Ni block and Nb sheet into different beakers, pour a certain amount of absolute ethanol (just submerged the raw materials), and use Clean with an ultrasonic cleaner for 15 to 20 minutes to remove scale and impurities on the surface of raw materials. Then dry the cleaned raw materials with a blower at low temperature to obtain clean Co, Cr, Ni, Nb raw materials, which are put into clean sample bags for later use.

[0061] Step 2, weighing Co, Cr, Ni, Nb metal elemental raw materials accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com