Motor vehicle headlamp

A technology for headlights and motor vehicles, which is applied to vehicle components, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problem of increasing weight, difficulty in installing a lamp module to a headlight housing, and increasing the size of the lamp module. Size and other issues, to achieve the effect of efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

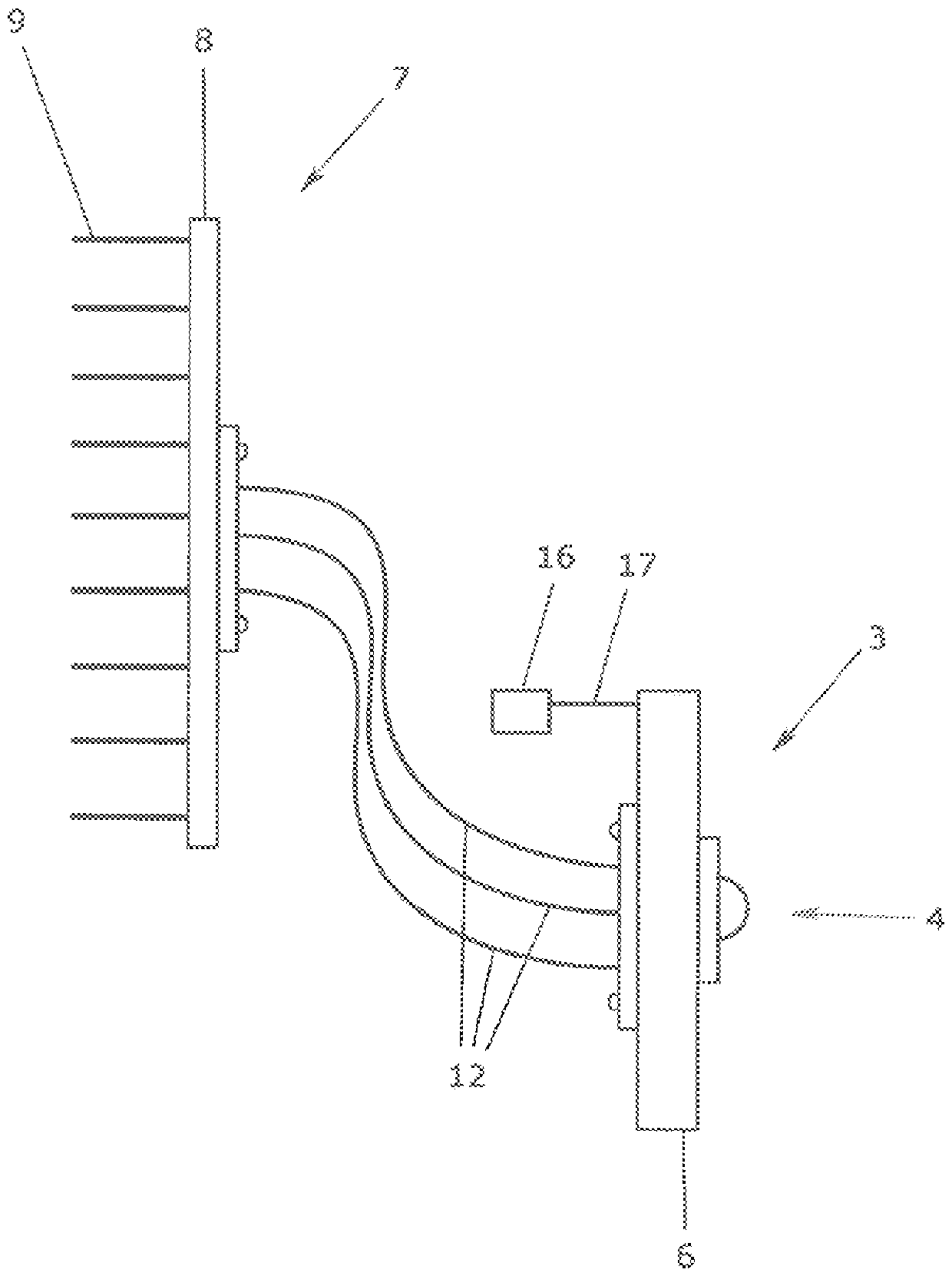

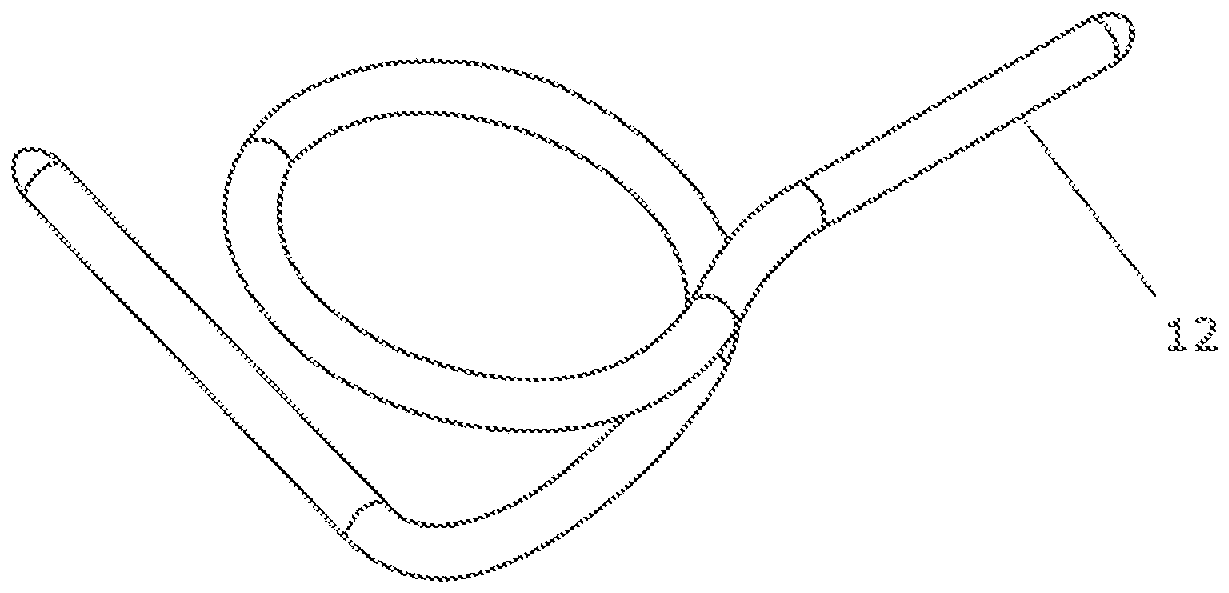

[0027] figure 1 A motor vehicle headlight 1 according to the invention with a headlight housing 2 in which at least one light module 3 is arranged is shown in a schematic, clearly simplified illustration. The lamp module 3 has a luminous means 4 , wherein at least one laser diode 5 is preferably provided as the luminous means 4 . However, other light emitting means 4 can also be used, for example light emitting diodes, DLP components or the like. The luminous means 4 are fastened on a carrier frame 6 . Furthermore, the motor vehicle headlight 1 includes at least one cooling element 7 which is provided for extracting heat from the light module 3 . The cooling element 7 is arranged on the headlight housing 2 in such a way that the heat extracted by the lamp module 3 is emitted outside the headlight housing 2 . The cooling element 7 has a cooling body 8 and cooling fins 9 , wherein the cooling fins 8 are arranged outside the headlight housing 2 . The heat sink 8 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com