Non-contact wire diameter measuring device and method

A non-contact, measurement method technology, applied in the field of measurement, can solve the problems of potential safety hazards, the complexity of non-contact wire diameter measuring instruments, and the high price of laser range finders, and achieve the reduction of random measurement errors, low cost, and easy shooting The effect of low angle requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

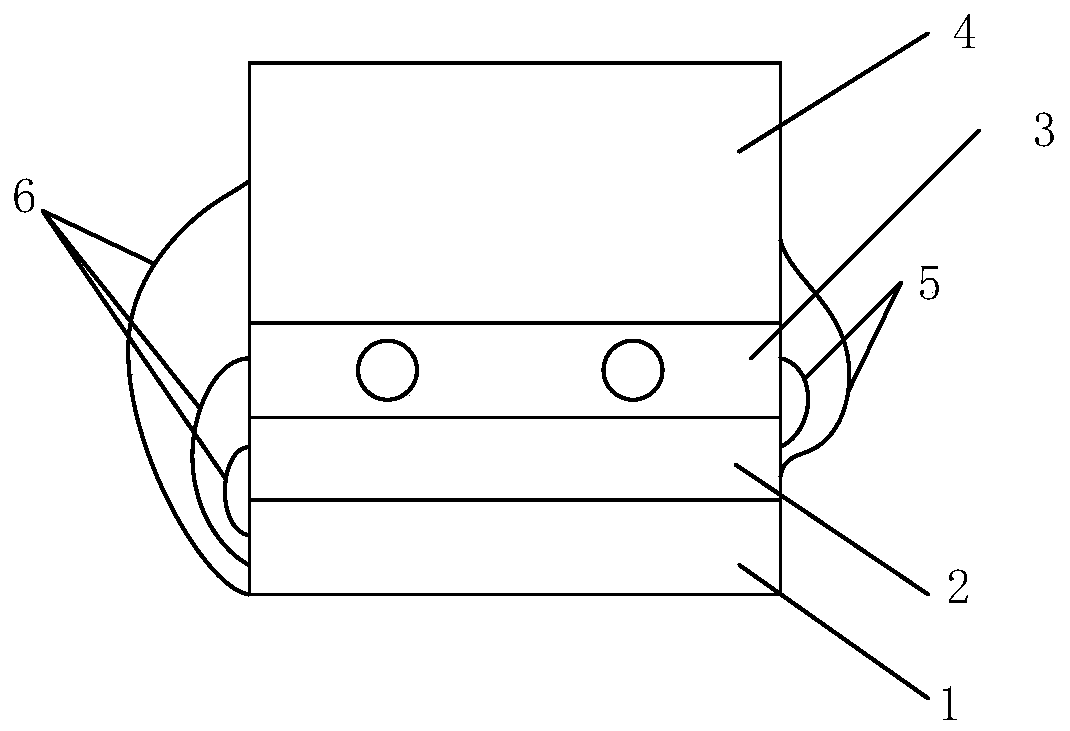

[0041] Such as figure 1 As shown, the present invention provides a non-contact wire diameter measuring device, which includes a binocular stereo vision depth camera 3, a central processing unit 2, a display 4, and a power source 1, wherein the power source 1 is respectively binocular stereo vision through a power supply line 6 The depth camera 3, the central processing unit 2, and the display 4 are powered, and the central processing unit 2 is respectively connected to the binocular stereo vision depth camera 3 and the display 4 through a signal transmission line 5 to realize two-way transmission of digital signals.

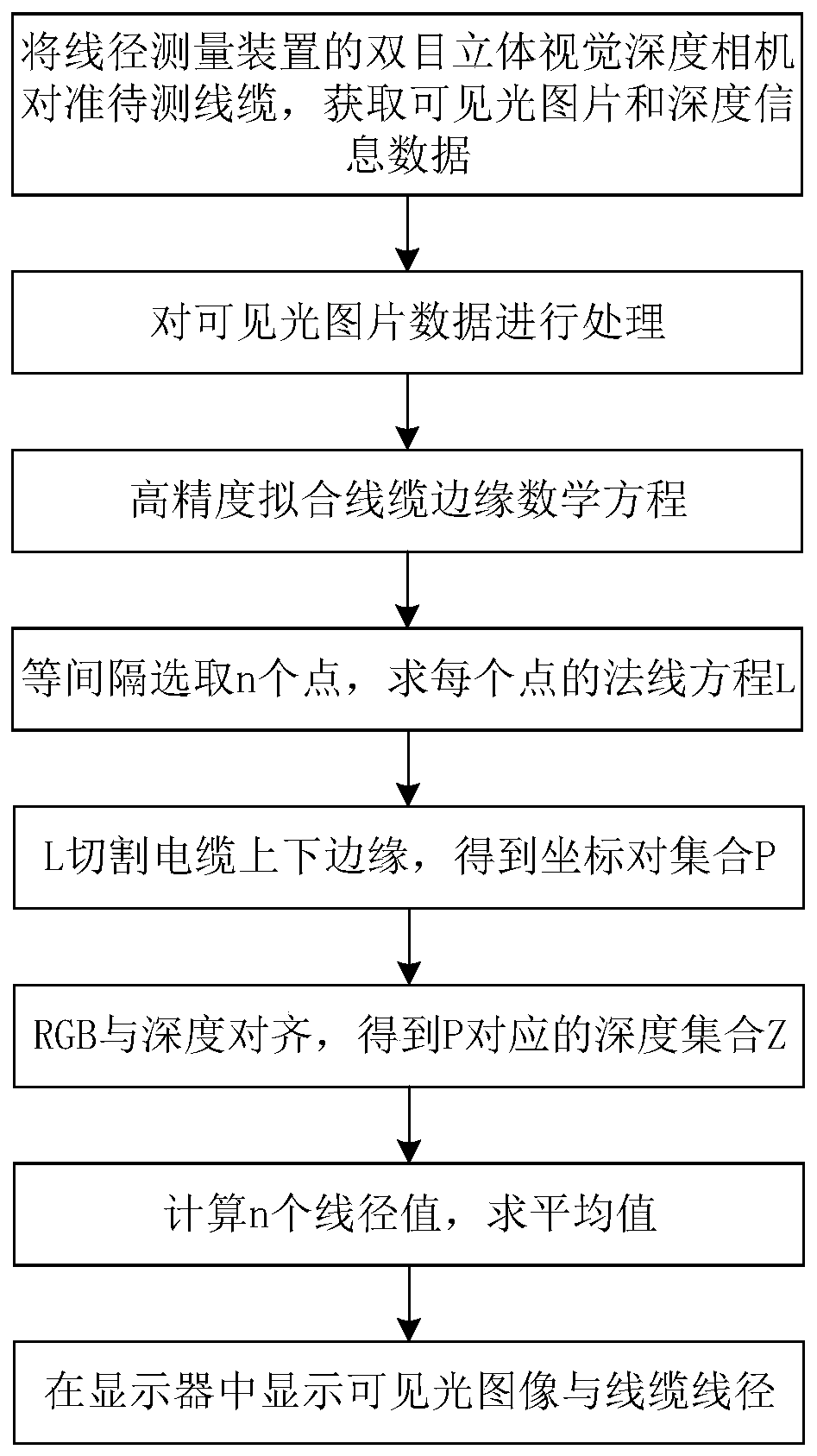

[0042] Cooperate figure 2 Shown is the flow chart of the non-contact wire diameter measurement method provided by the present invention, which specifically includes the following steps:

[0043] Step 1. Point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com