Cover-free dual mass flywheel with a centrifugal pendulum-type absorber

A dual-mass flywheel and centrifugal force pendulum technology, applied in the direction of rotation vibration suppression, spring/shock absorber, vibration suppression adjustment, etc., to achieve the effect of simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

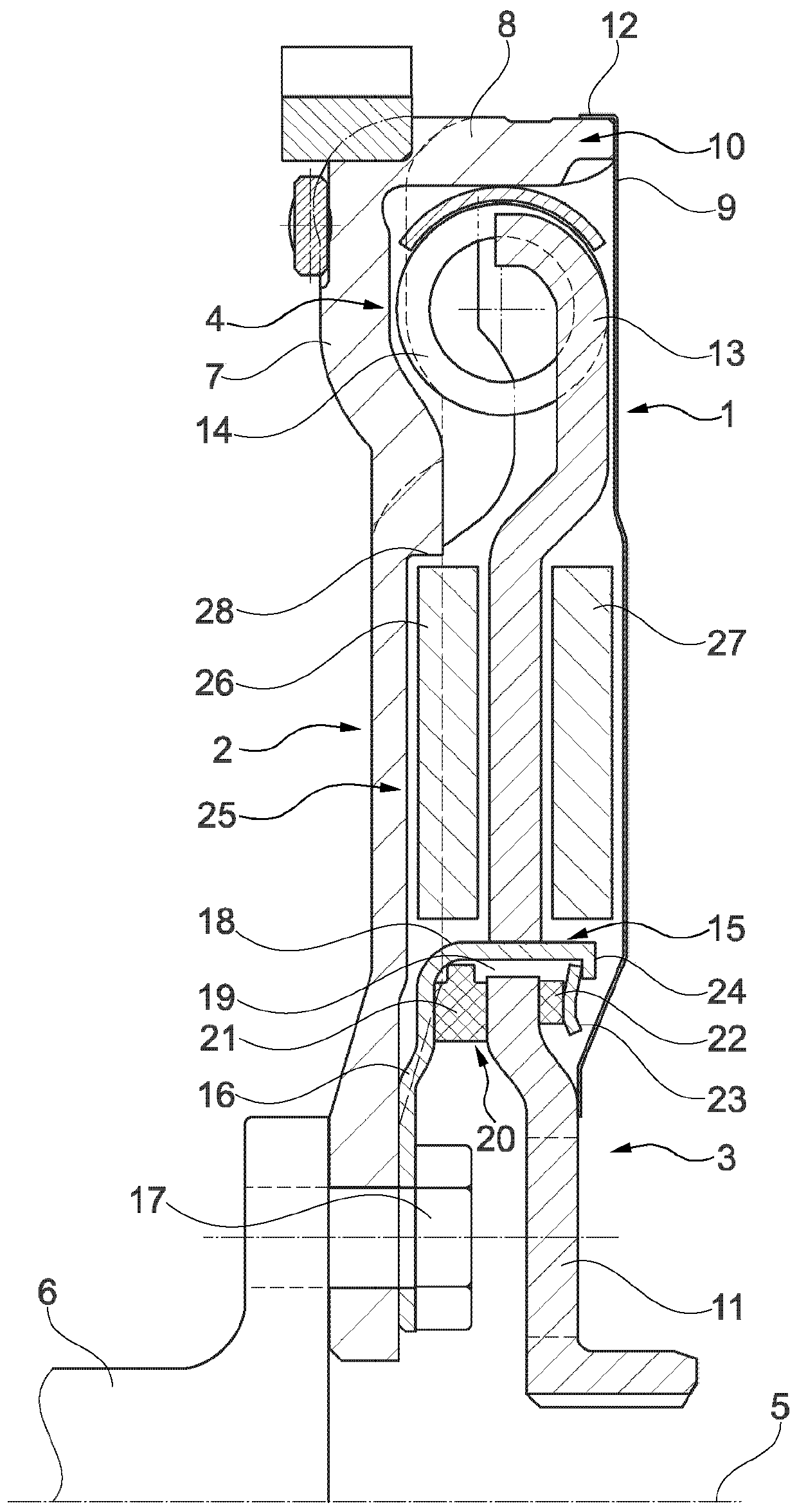

[0029] figure 1Shown is a dual-mass flywheel (ZMS) 1 , also known as a torsional damper, which is arranged in the drive train of a vehicle with a crankshaft (not shown) of an internal combustion engine and a vehicle clutch (not shown), in particular embodied as a double clutch. out). The torque of the internal combustion engine is transmitted here from the vehicle clutches to the drive wheels, for example via a switching gear and a differential gear in conjunction with a cardan shaft. The dual-mass flywheel 1 comprises a primary part 2 , also called primary mass, and a secondary part 3 or secondary mass, which are limited relative to each other about an axis of rotation 5 against the force of a spring-damper system 4 twist. The primary part 2 comprises a drive-side disk flange 7 fastened to the crankshaft flange 6 , which surrounds the spring-damper system 4 with an outer bent leg 8 .

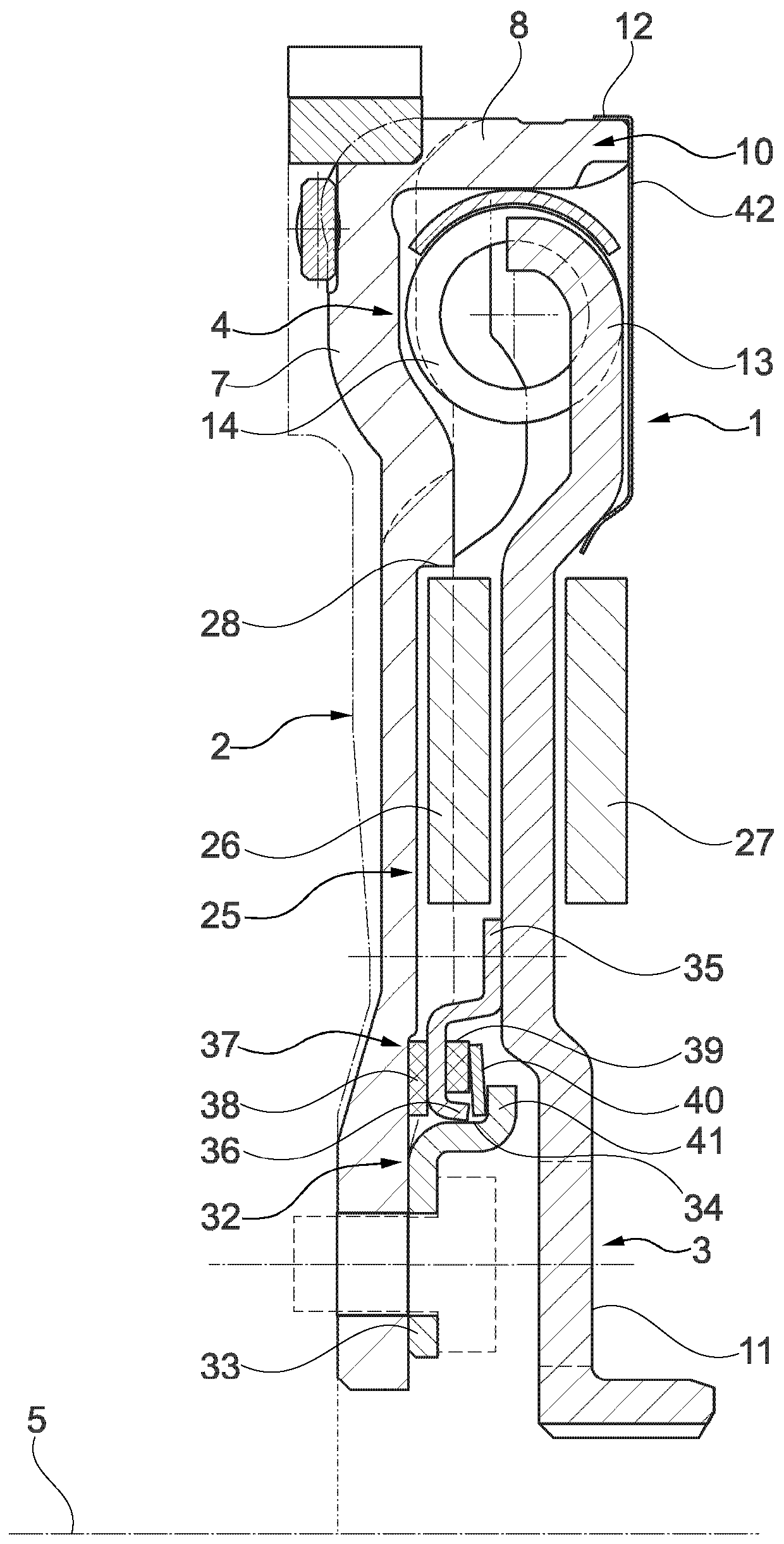

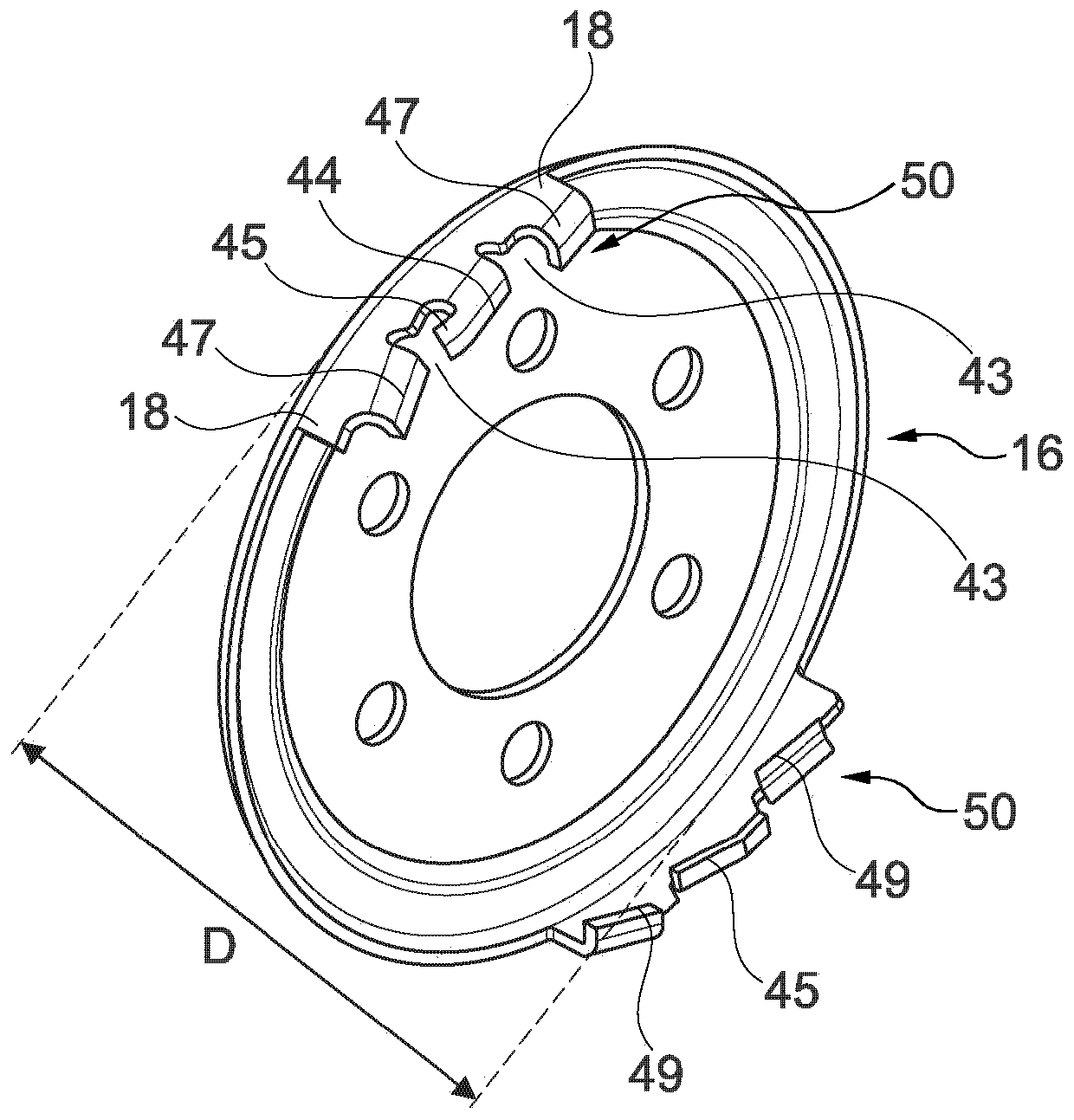

[0030] On the clutch side or on the output side, the thin-walled, disc-shaped sheet meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com