Anastomotic nail manufacturing and mounting integrated production technology process

A production process and technology of staples, applied in the direction of nails, connecting components, pins, etc., can solve problems such as operation failure, affecting the shape of titanium nails, and inability to ensure sharp corners, so as to reduce the risk of surgery and improve the qualified rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

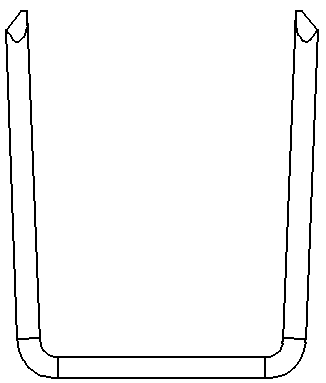

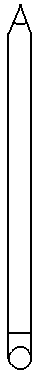

[0027] Such as Figure 1-2 As shown, the staple is U-shaped, and both ends of the staple have two oblique cuts, and the inside height of the cuts at both ends of the staple is higher than the height of the outside, so the inside of both ends of the staple is a sharp part.

[0028] The integrated production process of staple making and binding includes the following steps:

[0029] Clean the titanium wire first, then pull the titanium wire from the titanium wire reel through the nylon guide wheel, the tension wheel, and connect to the wire drawing servo motor, and then pull out the desired length to the position to be cut by the wire drawing servo motor.

[0030] Due to the reaction force of the guide wheel and the tension wheel, the titanium wire will straighten the titanium wire and relieve the stress when the wire drawing servo motor is pulled. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com