A high bonding strength electric knife head and its preparation method

A technology combining strength and electrosurgery, applied in the direction of heating surgical instruments, etc., can solve the problems of low interface strength, easy debonding of adhesives, weak connection of insulating heads, etc., to enhance interface strength, avoid interface deformation or even cracking, improve The effect of interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

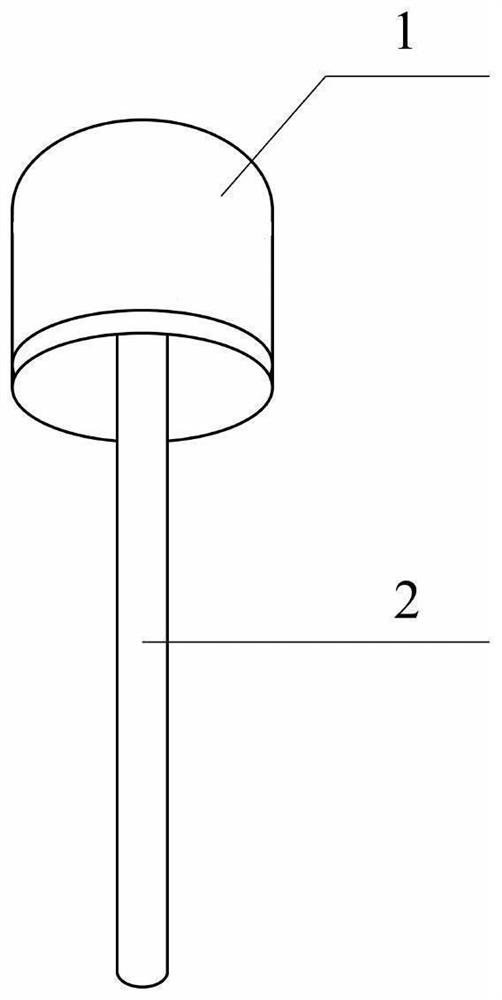

Image

Examples

Embodiment 1

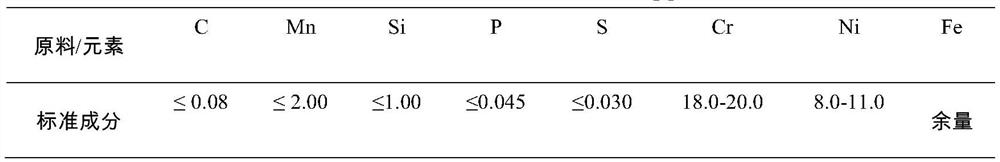

[0046] (1) Preparation of powder and binder: take zirconia powder with an average particle size of 30nm as raw material A, and add 20% of the volume of raw material A with zirconia powder with an average particle size of 3 μm to obtain a mixture M, press the mixture M 48% of the total volume is used as binder; 304 stainless steel powder with an average particle size of 40 μm is used as raw material B, and 44% of the total volume of raw material B is used as binder. The main components (mass percentage) of the binder are: polyethylene glycol 24%, polyoxymethylene 63%, polypropylene 7%, ethylene-ethylene acetic acid copolymer 6%, and the sum of the above components is 100%

[0047] (2) Mixing: Under the protection of argon, keep the material temperature at 180°C, respectively mix the mixture M, the raw material B powder and the corresponding binder for 2 hours, and obtain the feeding materials A and B respectively;

[0048] (3) Injection molding: The mold cavity is designed acco...

Embodiment 2

[0052] (1) Preparation of powder and binder: take zirconia powder with an average particle size of 30nm as raw material A, and add 25% of the volume of raw material A with zirconia powder with an average particle size of 3 μm to obtain a mixture M, press the mixture M 48% of the total volume is used as binder; 304 stainless steel powder with an average particle size of 40 μm is used as raw material B, and 44% of the total volume of raw material B is used as binder. The main components (mass percentage) of the binder are: polyethylene glycol 24%, polyoxymethylene 63%, polypropylene 7%, ethylene-ethylene acetic acid copolymer 6%, the sum of the above components is 100%

[0053] (2) Mixing: Under the protection of argon, keep the material temperature at 180°C, respectively mix the mixture M, the raw material B powder and the corresponding binder for 2 hours, and obtain the feeding materials A and B respectively;

[0054] (3) Injection molding: The mold cavity is designed accordin...

Embodiment 3

[0058] (1) Preparation of powder and binder: take zirconia powder with an average particle size of 30nm as raw material A, and add 30% of the volume of raw material A with zirconia powder with an average particle size of 3 μm to obtain a mixture M, press the mixture M 48% of the total volume is used as binder; 304 stainless steel powder with an average particle size of 40 μm is used as raw material B, and 44% of the total volume of raw material B is used as binder. The main components (mass percentage) of the binder are: 24% polyethylene glycol, 63% polyoxymethylene, 7% polypropylene, 6% ethylene-ethylene acetic acid copolymer, and the sum of the above components is 100%

[0059] (2) Mixing: Under the protection of argon, keep the material temperature at 180°C, respectively mix the mixture M, the raw material B powder and the corresponding binder for 2 hours, and obtain the feeding materials A and B respectively;

[0060] (3) Injection molding: The mold cavity is designed acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com