Mounting structure of annular heating coil

A heating coil and installation structure technology, applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactors/fermenters for specific purposes, etc., can solve problems such as damage, distortion, etc., to avoid impact, Avoid distortion and avoid loss of production stoppage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

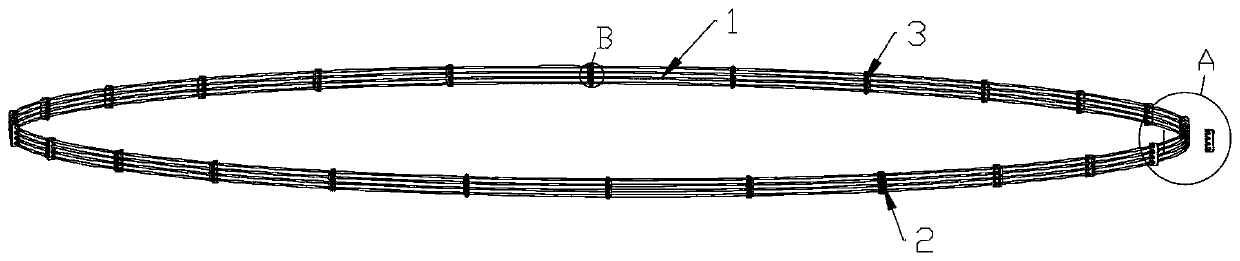

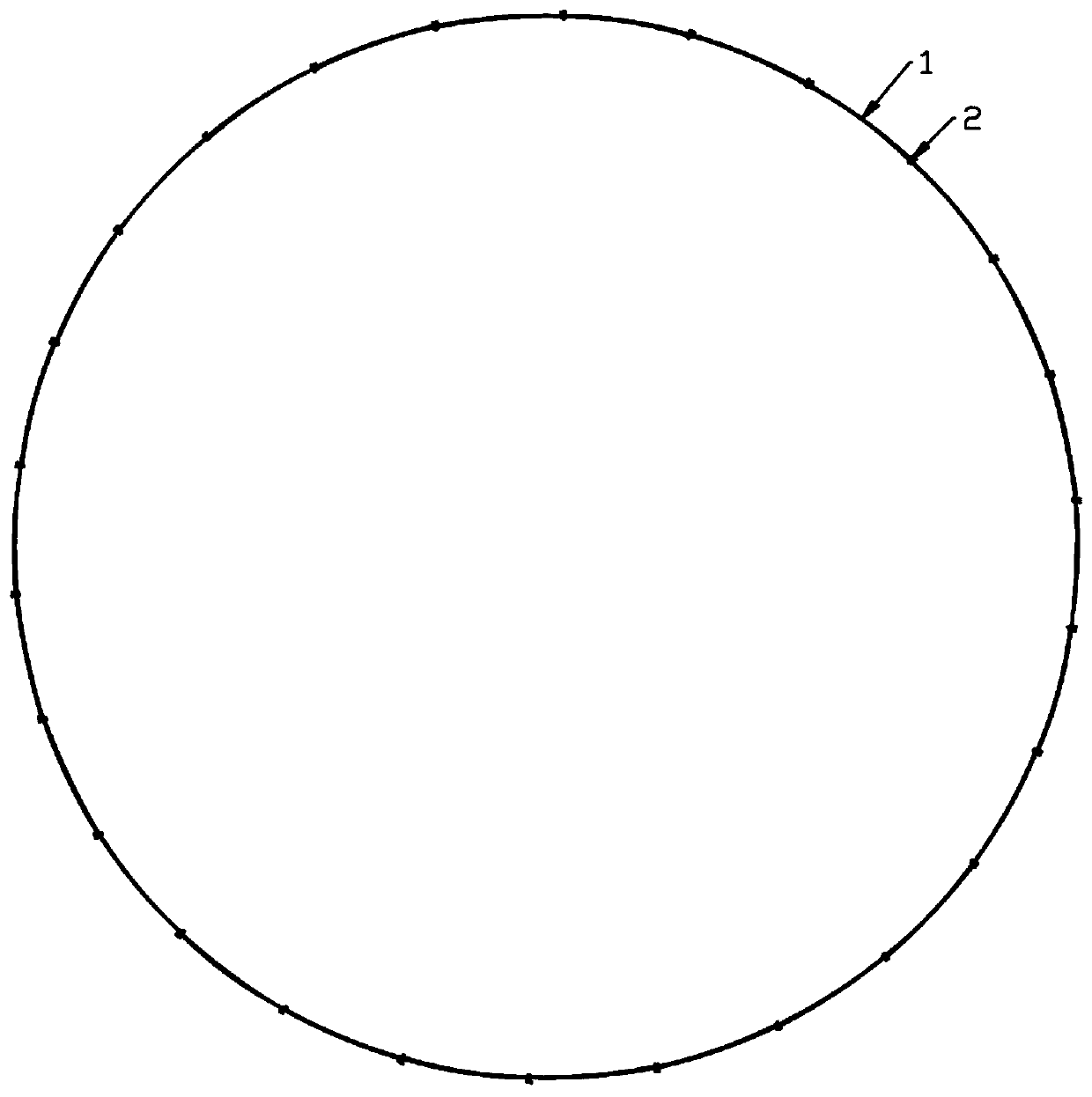

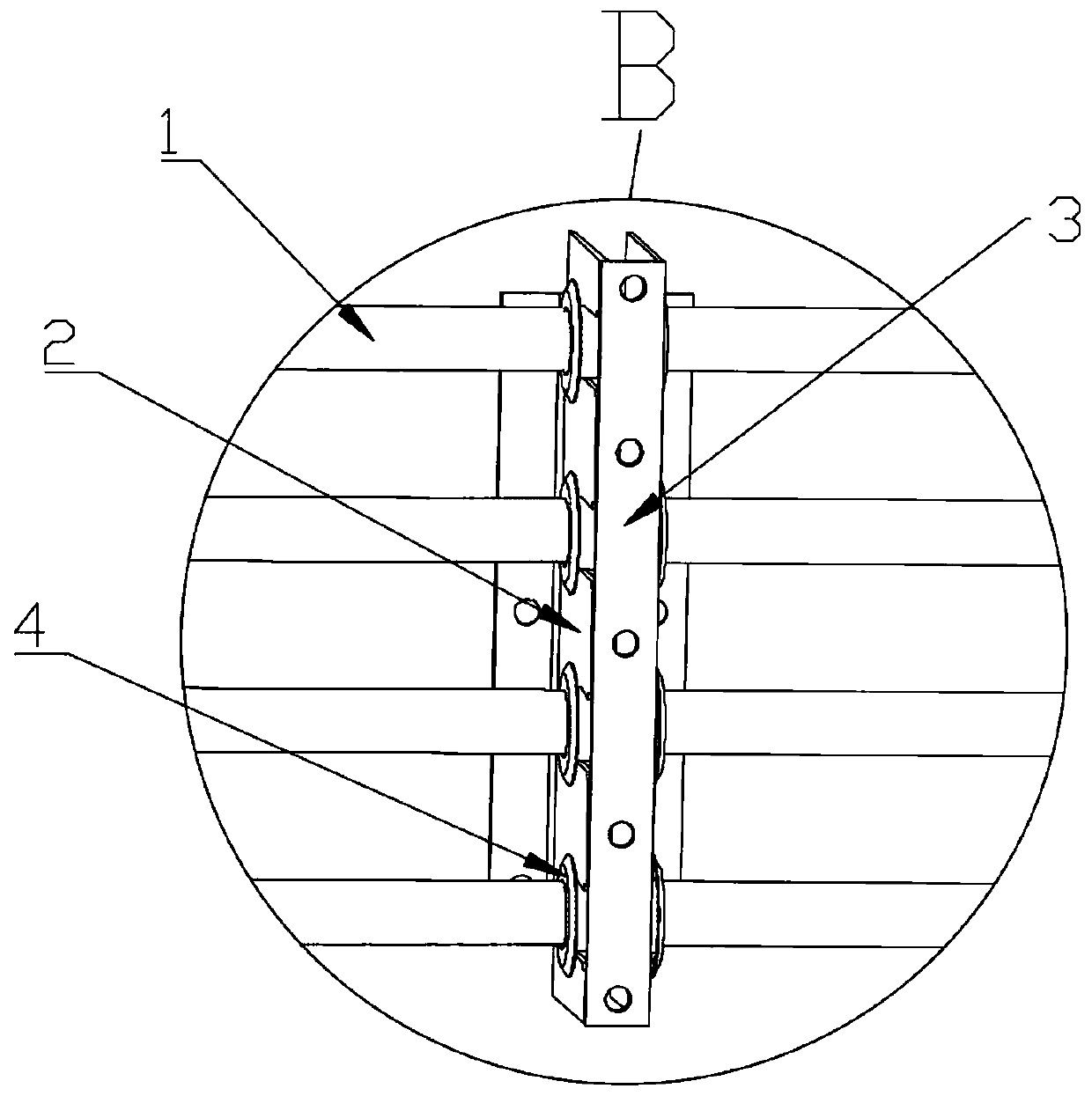

[0024] An installation structure of an annular heating coil is used for installing an annular heating coil 1 on the inner wall of an anaerobic reaction tank, and the annular heating coil 1 is arranged coaxially with the anaerobic reaction tank. Such as figure 1 As shown, the installation structure includes a fixed bracket 2, a pipe sleeve 4, and a limit seal plate 3 connected to each other. A fixed bracket 2, a pipe sleeve 4, and a limit seal plate 3 are used as a group. The circular heating coils 1 are distributed and arranged in the circumferential direction. Such as Figure 3-5 As shown, the fixed bracket 2 is provided with a mounting plate 202 integrally fixedly connected with the fixed bracket 2, and the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com