Annular inner support system for foundation pit and support replacement construction method

A foundation pit and ring-shaped technology, applied in the direction of foundation structure engineering, excavation, foundation structure test, etc., can solve the problems of cumbersome installation and removal, inability to increase symmetrical force, and inability to monitor symmetrical force, so as to solve the inconvenience of dismantling and prevent The effect of slipping and loosening, fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

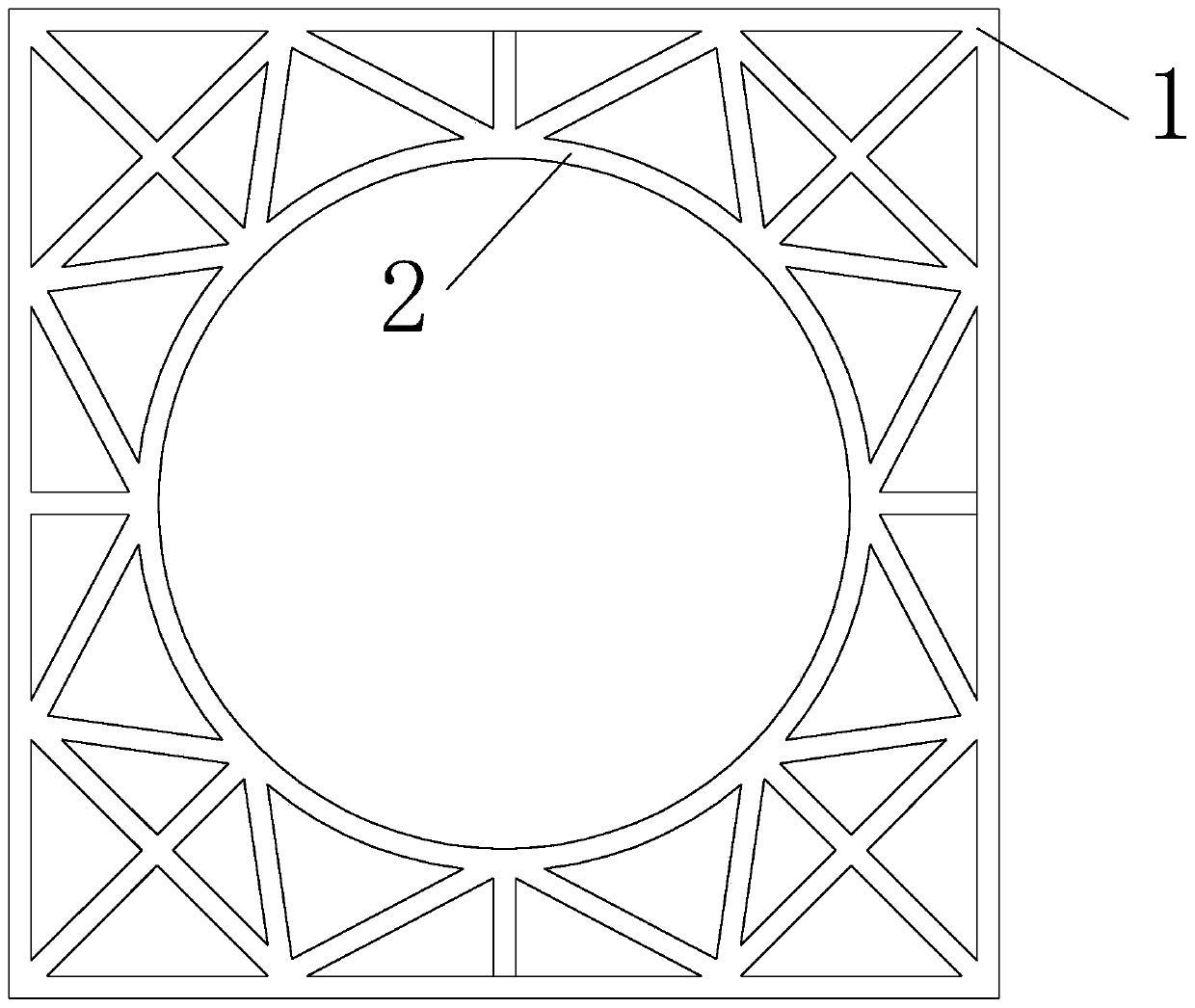

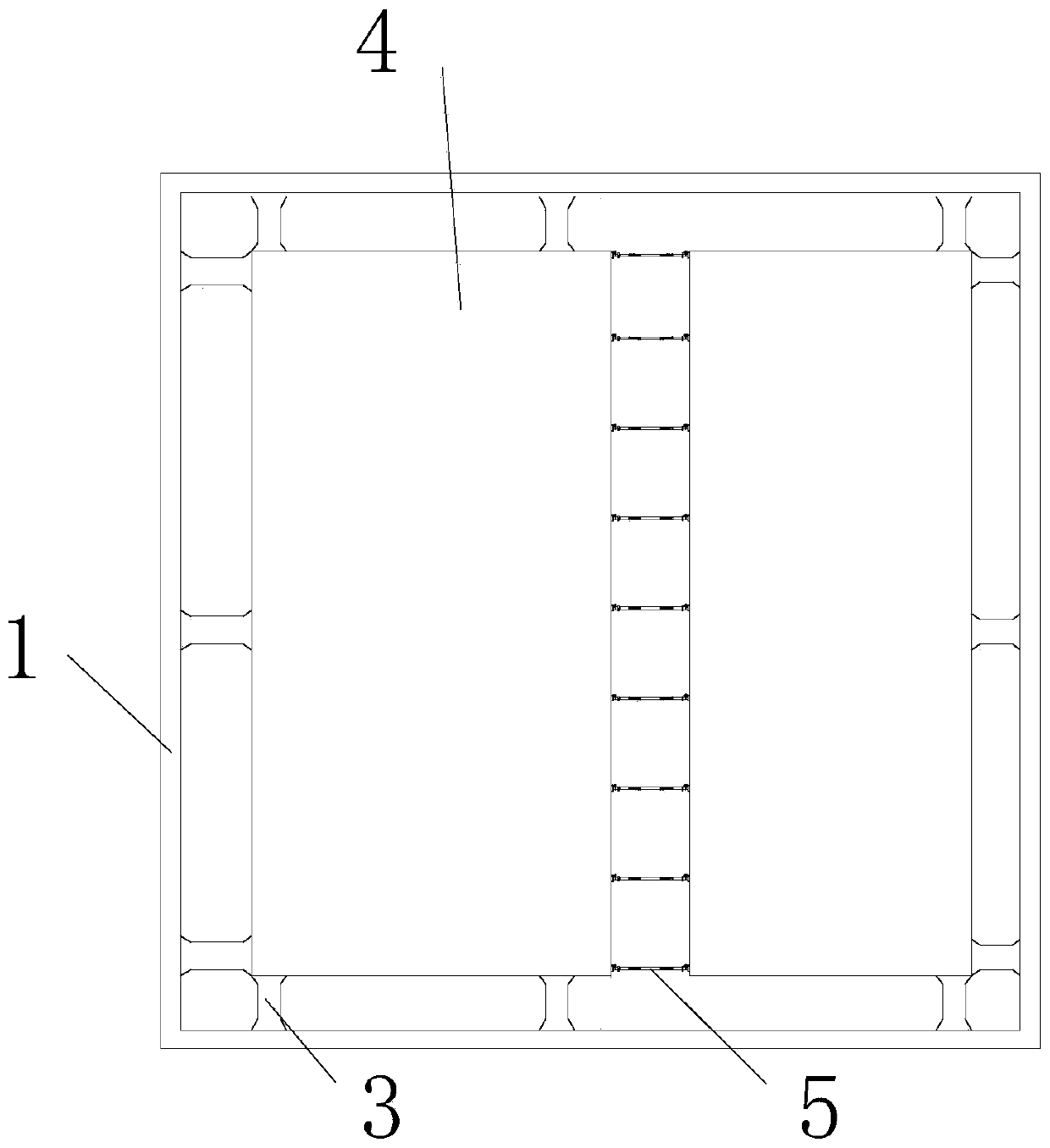

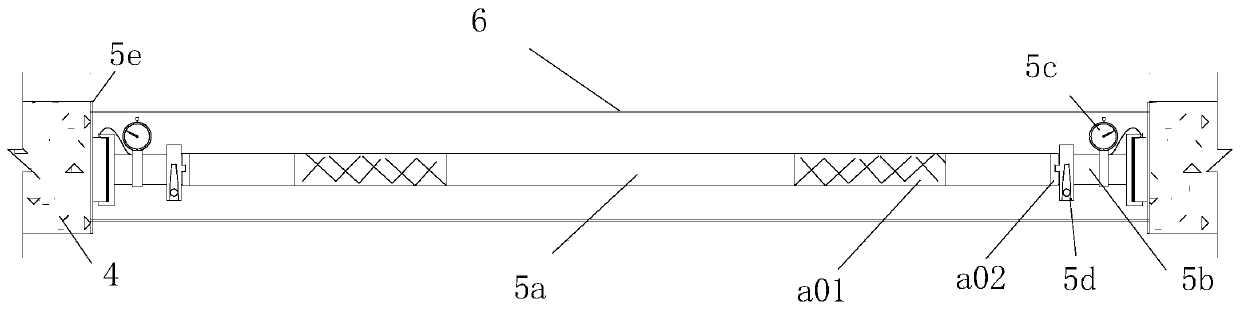

[0032] Such as Figure 1 to Figure 4 As shown, a ring-shaped internal support system of a foundation pit includes a vertical support member 1 arranged along the periphery of the foundation pit and a main structure 4 located in the foundation pit. The inner side of the vertical support member 1 is connected with a circular horizontal structure composed of reinforced concrete beams. The inner support 2, the concrete power transmission belt 3 is distributed between the periphery of the main structure 4 and the vertical support member 1, the main structure 4 is provided with a post-cast belt, and the post-cast belt is equipped with a post-cast steel bar 6 and a post-cast belt The dowel bar 5, the post-casting belt dowel bar 5 includes a main bar 5a and two sets of adjusting bars 5b located at both ends of the main bar 5a, a pressure sensor 5c, a locking mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com