Reheat steam temperature adjusting method based on hierarchical scheduling multi-model predictive control

A technology of predictive control and reheat steam temperature, applied in the field of thermal control and boiler steam temperature control of thermal power units, can solve the problems of difficult application of engineering practice, poor quality of reheat steam temperature control of thermal power units, etc., to improve thermal cycle efficiency and safety, less dynamic and steady-state deviations, and the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

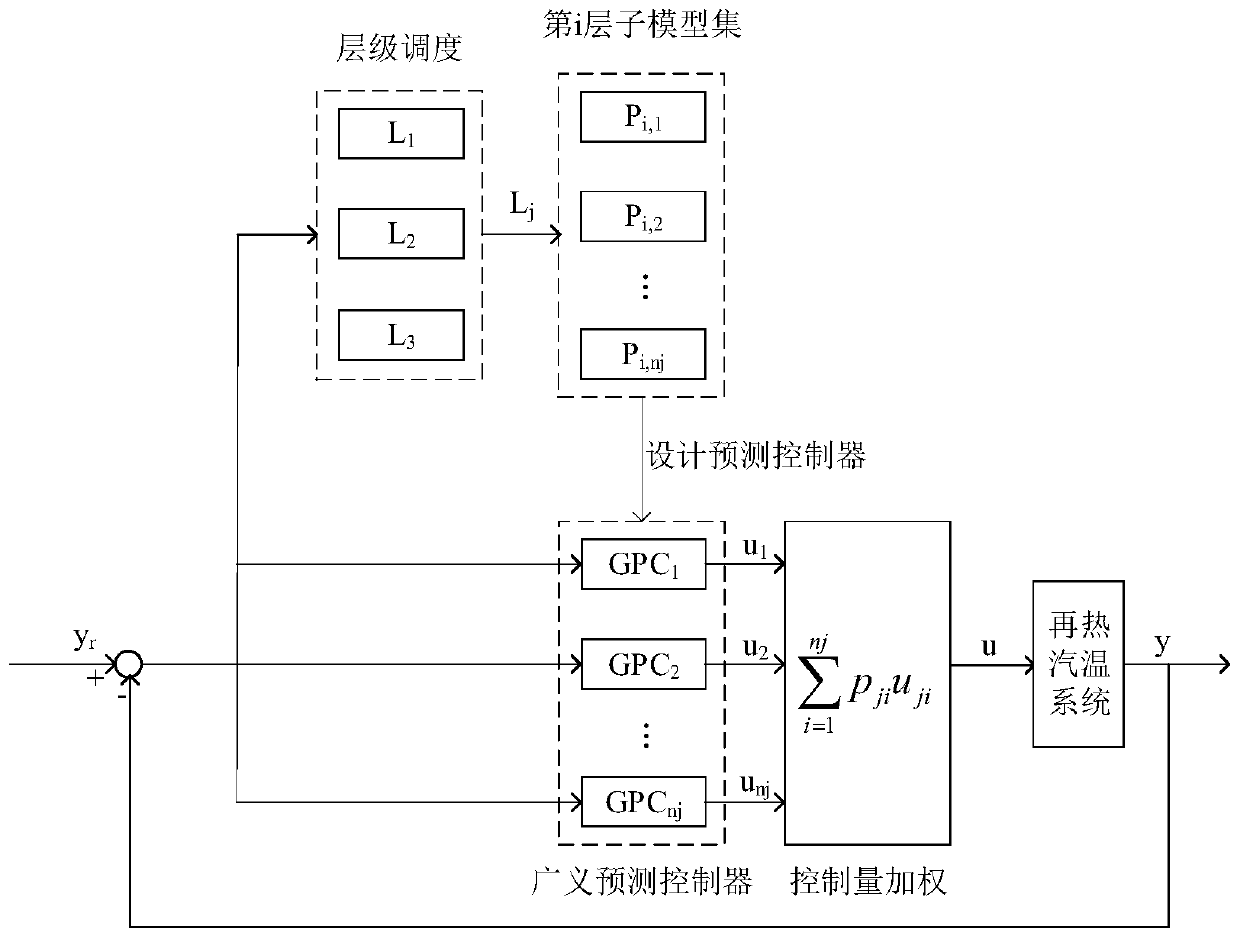

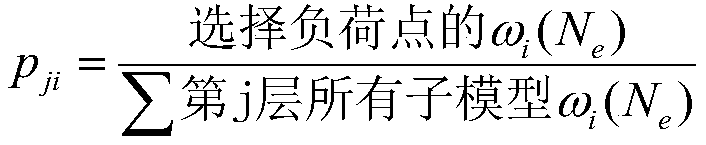

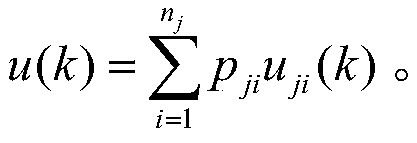

[0023] figure 1 Multi-model predictive control structure diagram for hierarchical scheduling, in the figure, y r Indicates the set value of reheat steam temperature, u nj Indicates that according to the selected L j The control quantity of the generalized predictive controller designed by the njth sub-model of the layer, u represents the weighted overall control quantity, that is, the flue gas baffle opening instruction, and y represents the actual reheat steam temperature under the action of the control quantity u. The reheat steam temperature adjustment method based on hierarchical scheduling multi-model predictive control, the specific implementation steps are as follows:

[0024] Step 1: According to the effect of the flue gas baffle in the 50%-100% load section of the thermal power unit on the final stage reheating steam temperature T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com