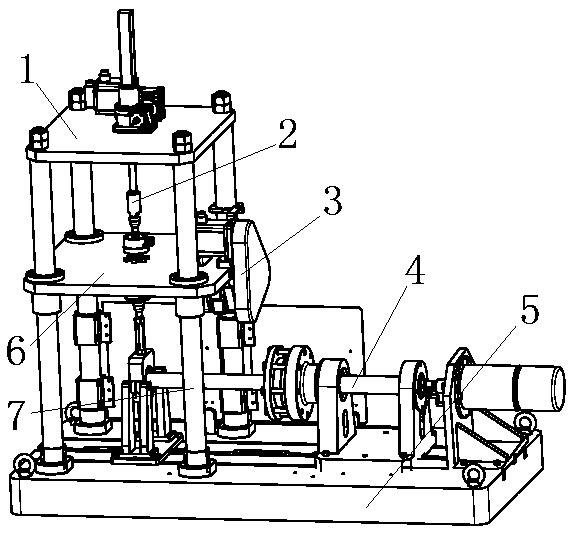

Wheel and axle bending fatigue test device

A bending fatigue and test device technology, which is applied in measuring devices, railway vehicle testing, and material strength testing using a stable bending force. It can meet the needs of less research and other problems, and achieve the effect of reducing processing costs and improving the quality of railway trains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

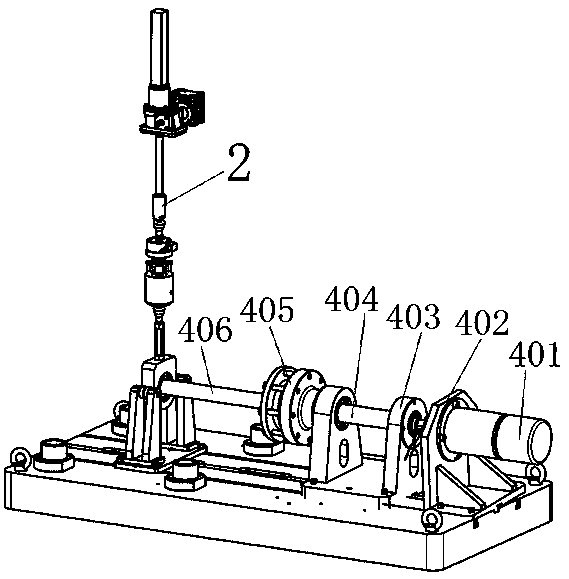

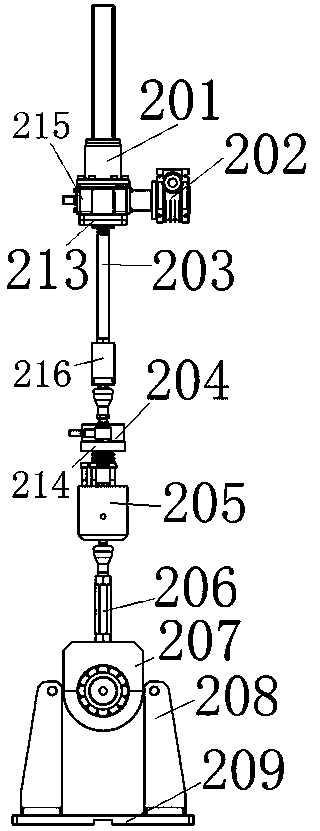

[0020] In the present invention, four pillars 7 arranged in a rectangular shape are fixed on one side of the bearing platform 5. The bearing platform 5 is a connector that is conveniently fixed or installed on other fixed equipment, and also carries all the mechanisms of the present invention. As a whole, the four pillars 7 play a supporting role, leaving space therebetween to facilitate the cooperation of other components in the movement space. The main components of the present invention are mainly divided into three parts: a longitudinal loading mechanism 2, a lateral movement mechanism 3 and a rotation mechanism 4, through which the corresponding forces are applied to test the three factors of longitudinal, lateral and rotation; The top supporting plate 1 is fixedly installed on the upper end of the root pillar 7, and the middle supporting plate 6 is installed in the middle; The lateral movement mechanism 3 is installed on the lower side of the support plate 6 through rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com