The welding sequence of a structural component determines the method, device, equipment and storage medium

A welding sequence and determination method technology, applied in design optimization/simulation, etc., can solve problems such as slow calculation speed, few types of welding processes, and inability to obtain accuracy, so as to reduce the amount of calculation and realize the effect of numerical simulation calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

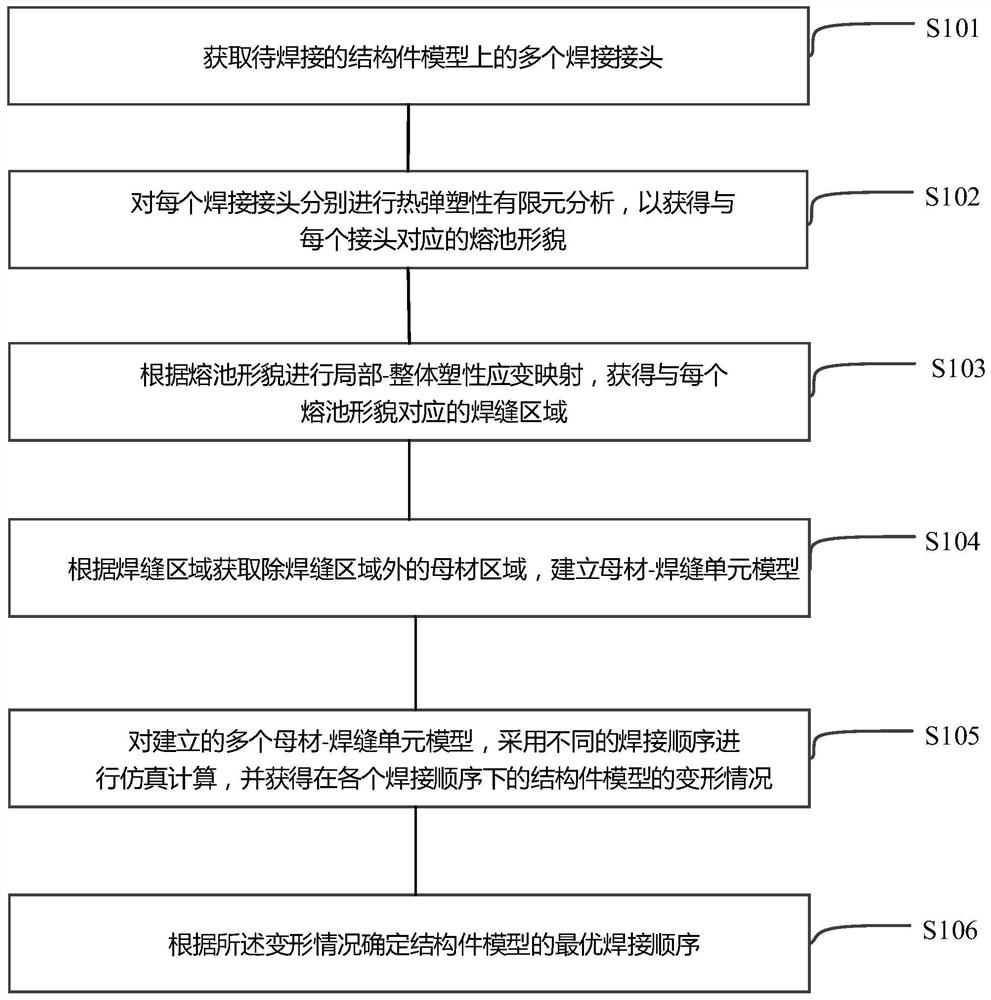

[0065] see Figure 1 to Figure 11 , the first embodiment of the present invention provides a method for determining the welding sequence of structural parts, which can be performed by a device for determining the welding sequence of structural parts (hereinafter referred to as the device for determining the welding sequence). In particular, one of the devices for determining the welding sequence or a plurality of processors, and at least include the following steps:

[0066] S101. Obtain a plurality of welding joints on the structure part model to be welded.

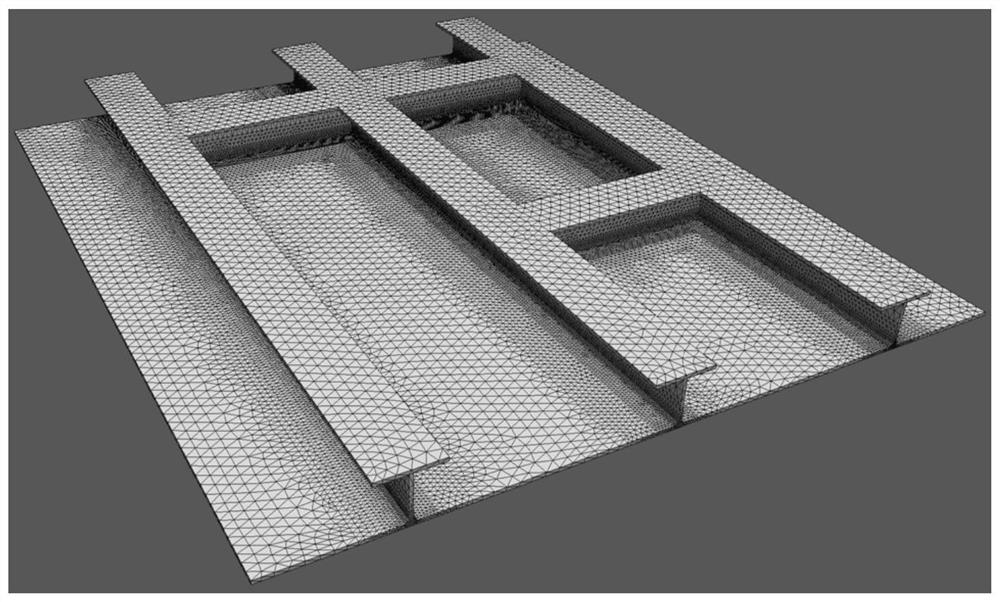

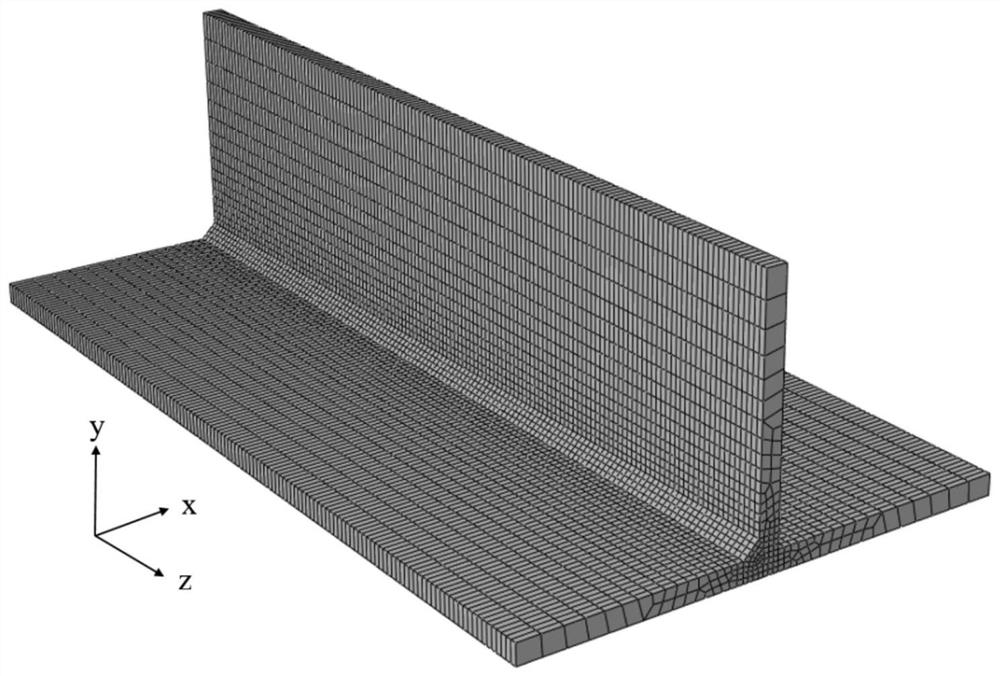

[0067] see figure 2 and image 3 , in this embodiment, the welding sequence determination device first obtains the pre-established three-dimensional geometric model of the structural member model to be welded and performs network division to generate a finite element model (such as figure 2 shown), according to the finite element model, obtain multiple welded joints on the structure model (such as image 3 ).

[0...

no. 2 example

[0088] see Figure 12 , the embodiment of the present invention also provides a welding sequence determination device for structural parts, including:

[0089] A welding joint obtaining unit 100, configured to obtain a plurality of welding joints on the structural part model to be welded;

[0090] The molten pool morphology acquisition unit 200 is configured to perform thermoelastic-plastic finite element analysis on each welded joint, so as to obtain the molten pool morphology corresponding to each joint;

[0091] A weld area acquisition unit 300, configured to perform local-overall plastic strain mapping according to the molten pool morphology, to obtain a weld area corresponding to each molten pool morphology;

[0092] 400, for obtaining base material areas other than the weld area according to the weld area, and establishing a base material-weld unit model;

[0093] The simulation calculation unit 500 is used to perform simulation calculations on the multiple established...

no. 3 example

[0106] The third embodiment of the present invention provides a welding sequence determination device for structural parts, including a processor, a memory, and a computer program stored in the memory, the computer program can be executed by the processor to achieve the above-mentioned The method for determining the welding sequence of the structural parts described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com