Cold spinning device applied to steel seamless gas cylinder

A seamless gas cylinder and cold spinning technology, which is applied in the field of gas cylinder cold spinning processing equipment, can solve problems such as uneconomical and practical, bearing wear, etc., achieve stable rotation, reduce maintenance and replacement costs, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

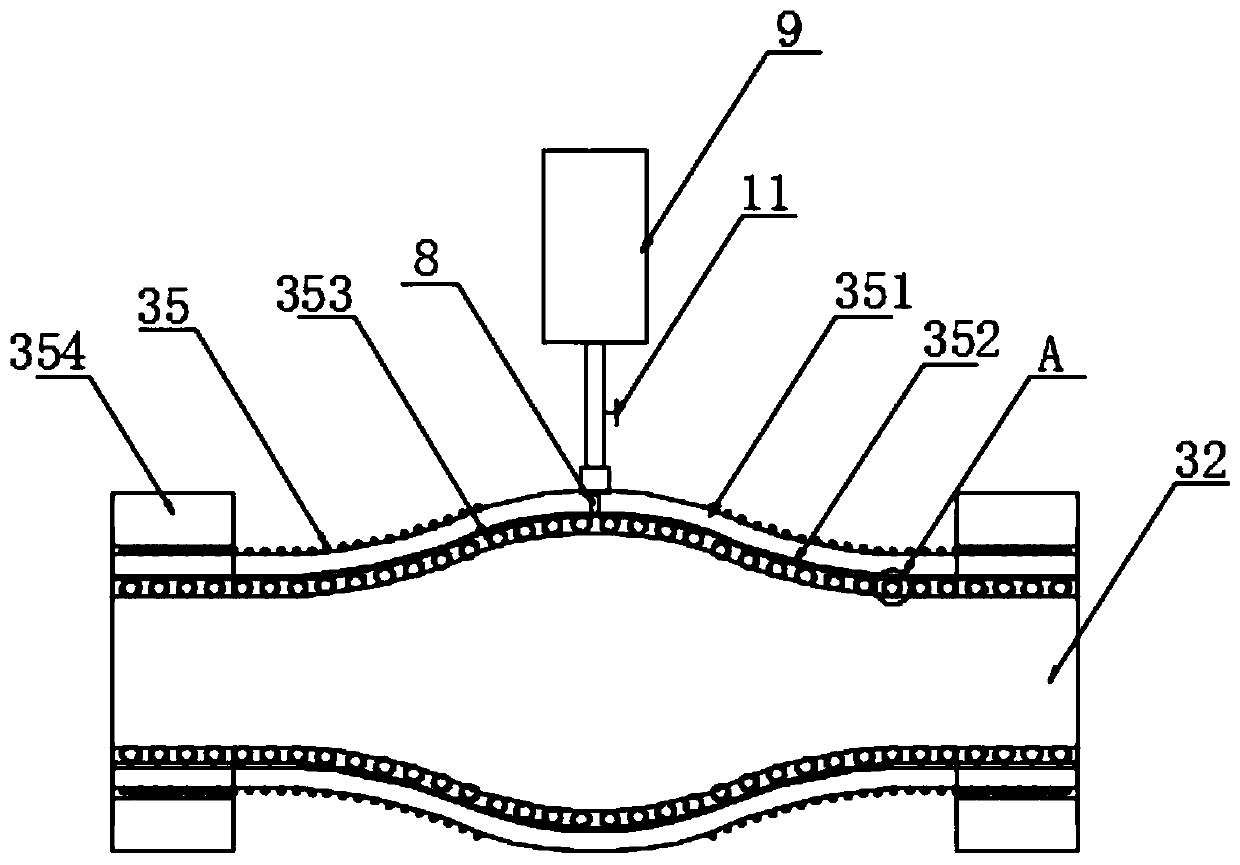

[0040] The specific embodiment is: connect the solenoid valve 11 with the controller that controls the cold rotation device, so that the timing opening and closing of the solenoid valve 11 can be controlled by the controller when the cold rotation device is in use, so that it can be realized according to the cold rotation without manual refueling. It is very convenient to use for intelligent control and automatic refueling according to the running time of the rotary device.

[0041] The working principle of the present invention:

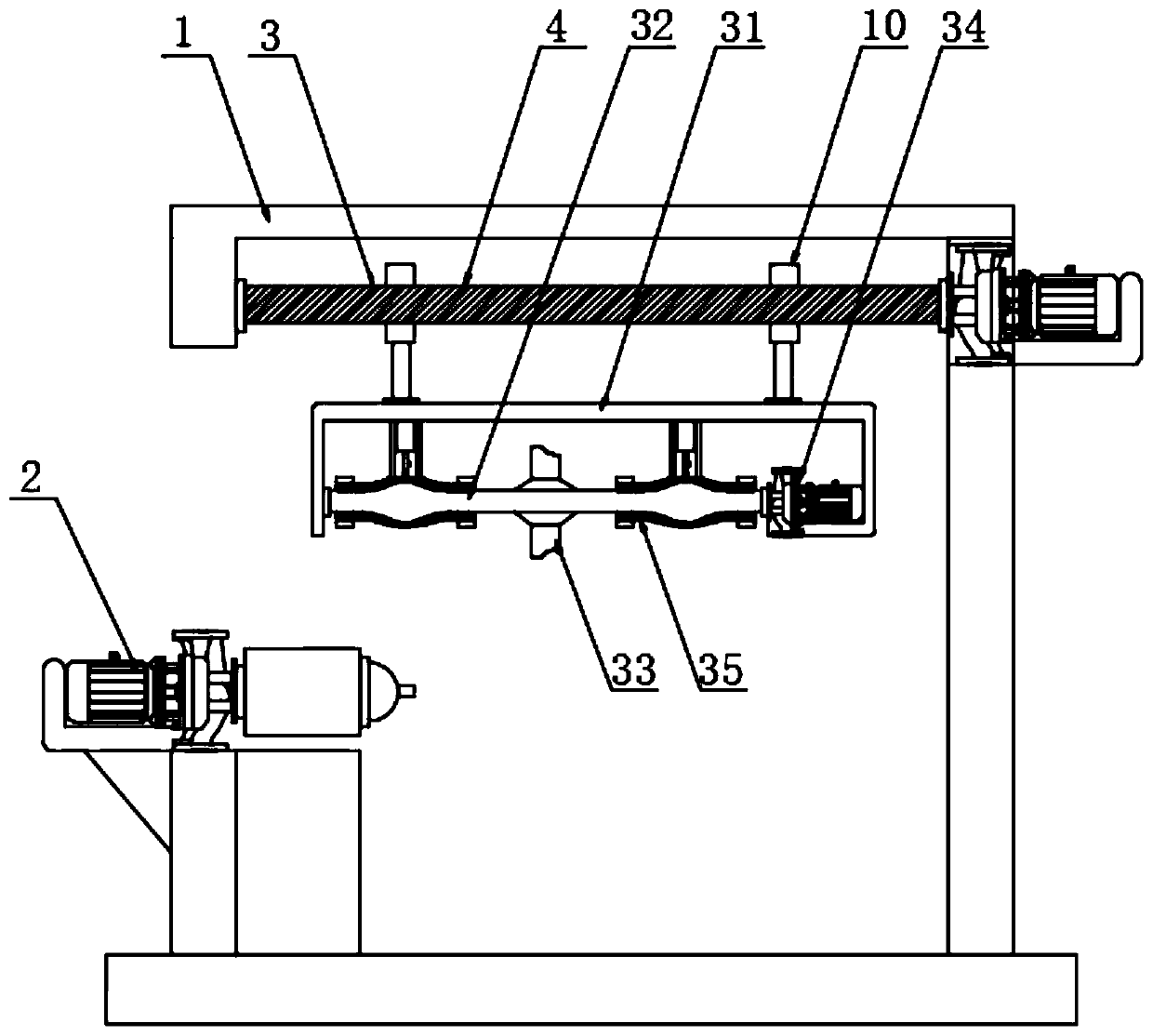

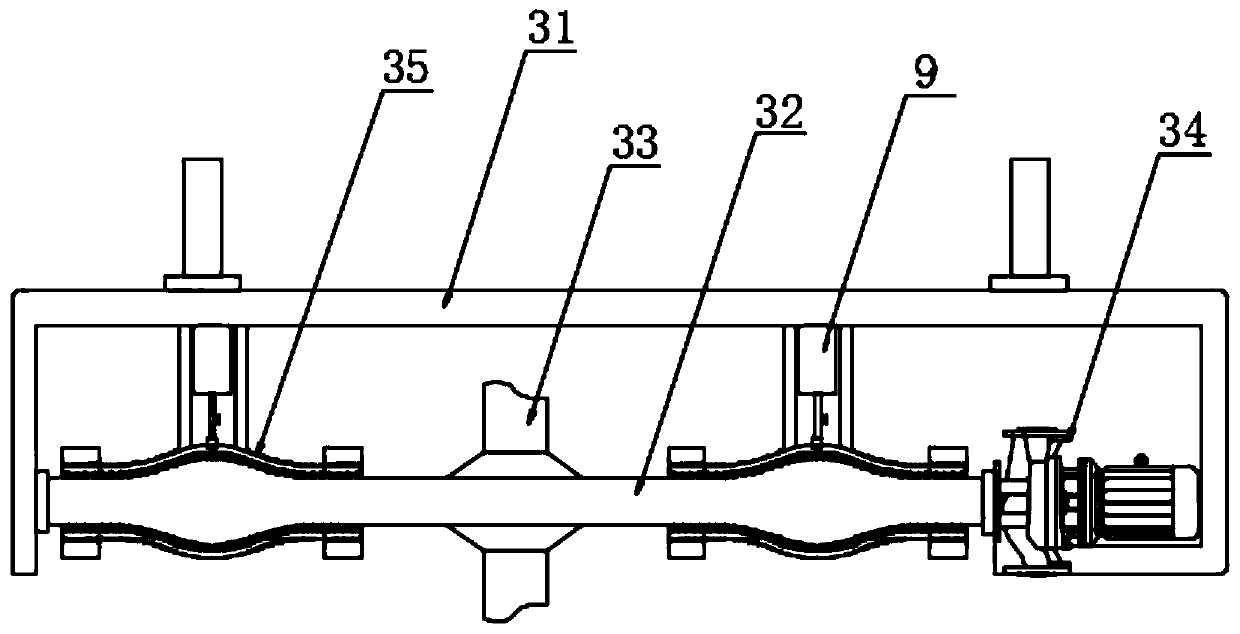

[0042] Refer to the attached Figure 1-7 , when the whole device is working, the preform clamping mechanical arm clamps the preform, the No. 2 servo motor drives the preform clamping mechanical arm to rotate, the screw rod 4 drives the rotary wheel mechanism 3 to move left and right, and the No. 1 servo motor 34 passes The special-shaped rotating shaft 32 drives the rotary wheel 33 to rotate to realize the processing of the outer wall of the prefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com