Movable track lifting device

A mobile and rail-based technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problem of inability to apply variable cross-section high-rise bridge main towers, limited construction scope, and scope of application. narrow and other issues, to achieve the effect of simple installation and fixation, wide application range and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

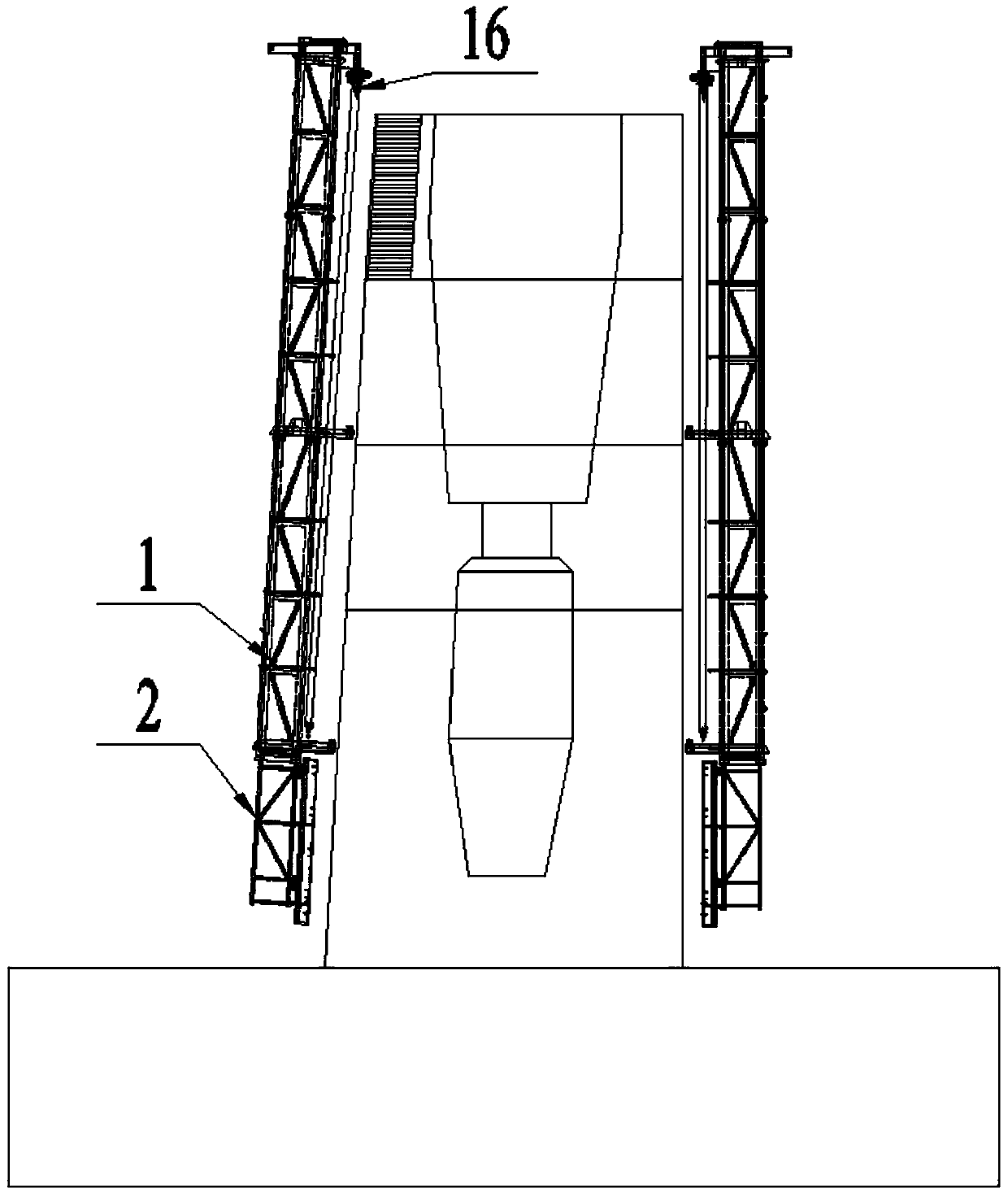

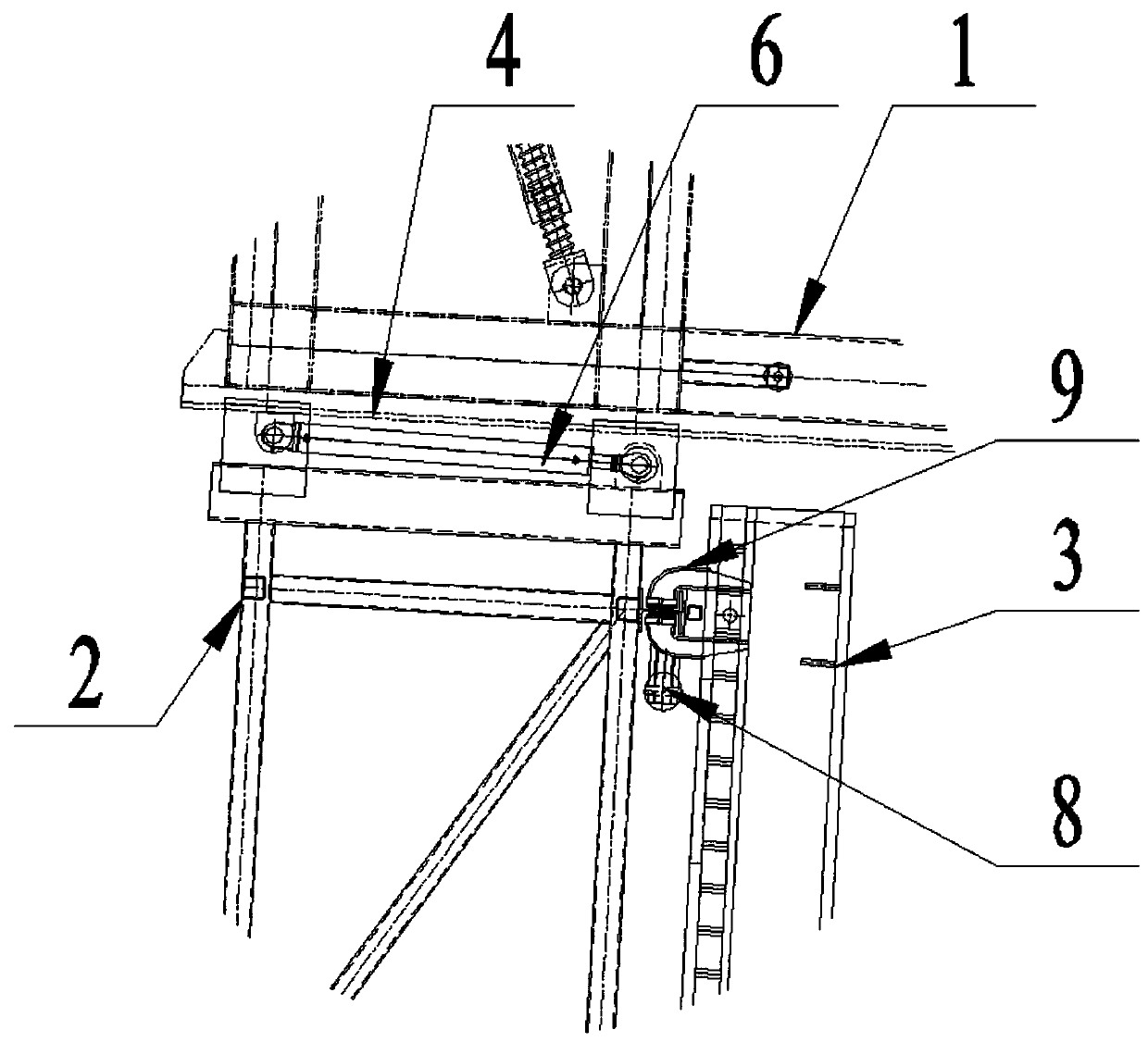

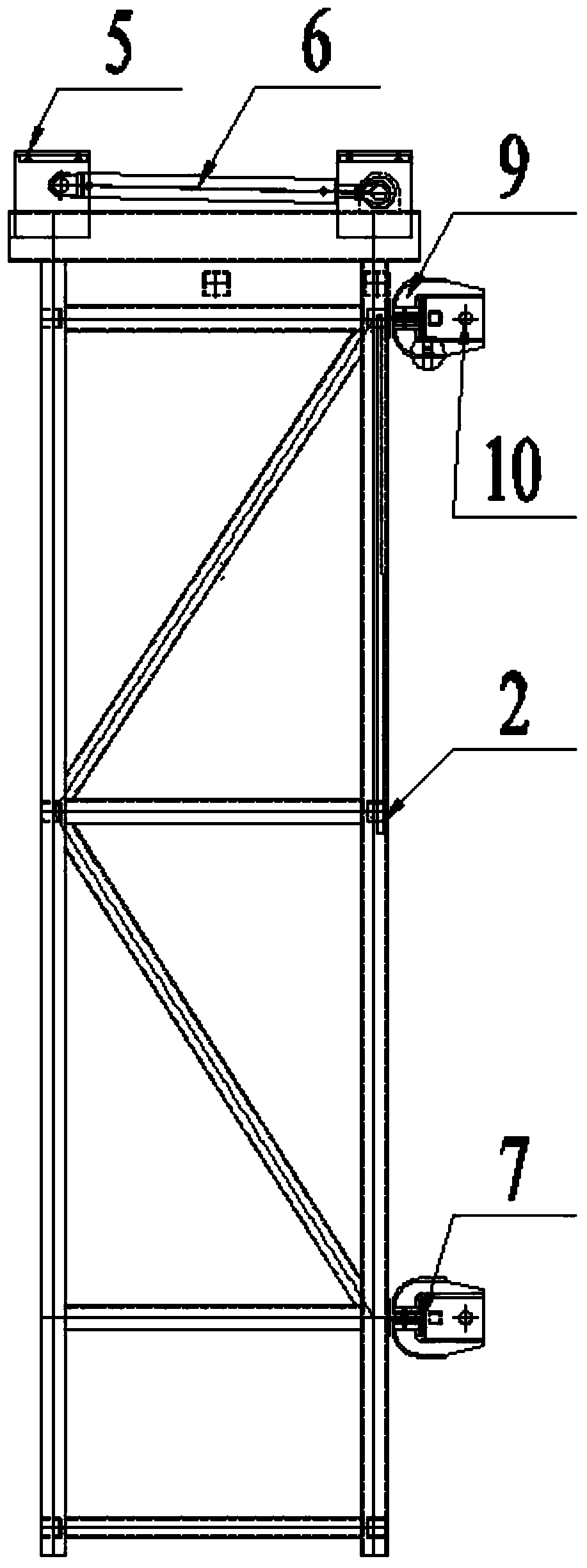

[0037] Such as Figure 1-10 , a movable track lifting device, the lifting device of this embodiment is used to lift the track unit 3, so that the track unit 3 can be reused repeatedly, reducing the cost of the track structure. The hoisting device of the present embodiment comprises a fixed truss 1 and a movable truss 2, such as figure 1 As shown, the fixed truss 1 of this embodiment is anchored on the finished concrete surface through embedded parts, and the movable truss 2 is a movable truss structure connected to the fixed truss 1 in a longitudinally movable manner.

[0038] Such as figure 2 As shown, the lower end of the fixed truss 1 is provided with a longitudinal guide rail 4 extending in the longitudinal direction, the movable truss 2 is provided with a sliding shoe 5 slidingly connected to the longitudinal guide rail 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com