External-flat-type high-pressure rotary jet grouting device for complex formations in underground coal mines and method

A technology of complex strata and high-pressure jet spraying, which is applied in earthwork drilling, wellbore/well components, drilling with liquid/gas injection, etc. It can solve the problems of difficult hole formation, poor stability of the borehole wall, and easy drill sticking, etc. problems, to achieve the effect of increasing the consolidation rate, reducing or accidents in the hole, and reducing the upward return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

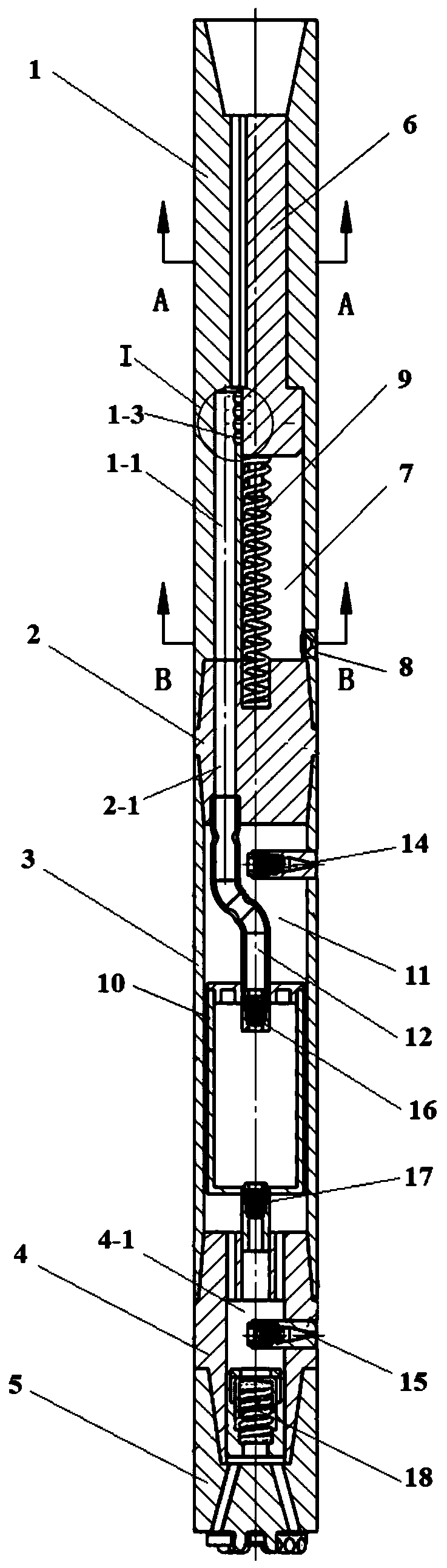

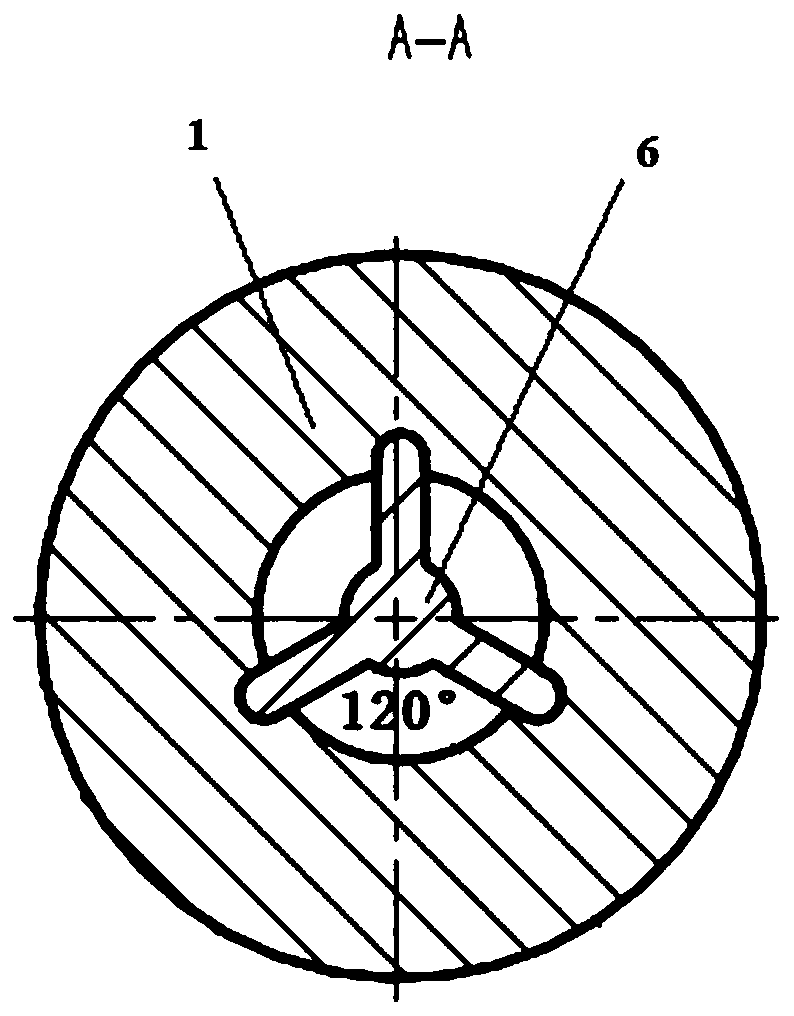

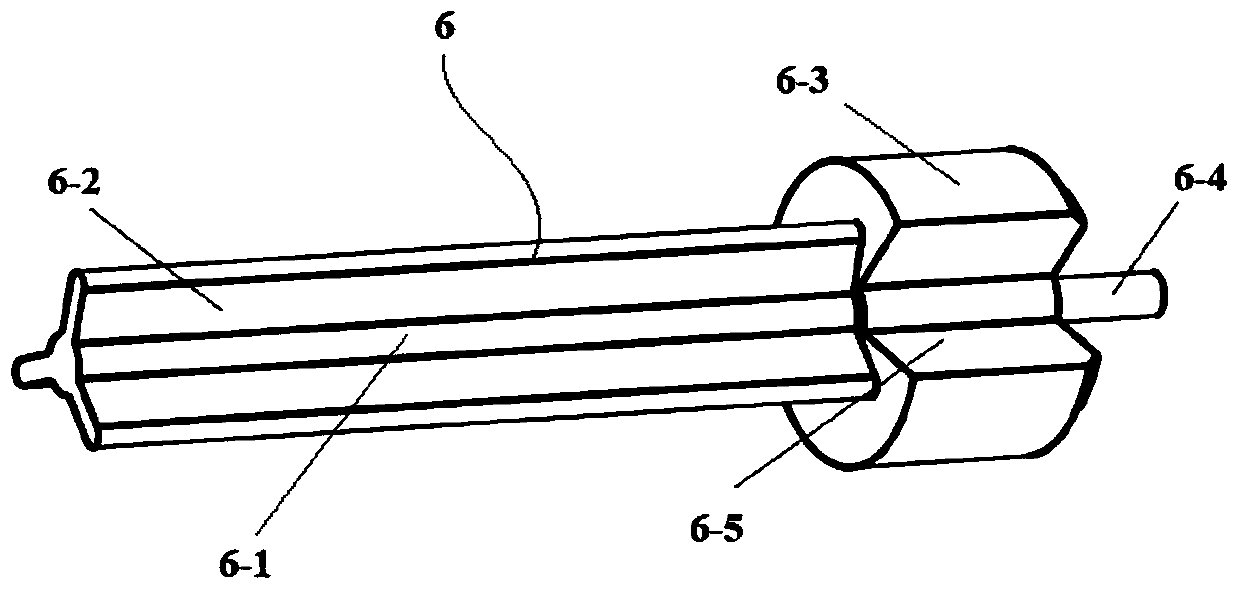

[0055] Such as Figure 1 to Figure 9 As shown, this embodiment provides an outer flat type high-pressure jet grouting device for complex underground formations in coal mines, which includes an outer water pipe 1, a middle joint 2, a lower outer pipe 3, a drill joint 4 and an outer pipe connected coaxially in sequence. A flat drill bit 5; a special-shaped piston 6 that can move axially is arranged in the water-passing outer pipe 1, and the inner space of the water-passing outer pipe 1 between the end of the special-shaped piston 6 and the end of the middle joint 2 is an expansion chamber 7, and the expansion chamber 7 is provided with a nozzle 8 on the side wall of the outer water pipe 1; a limit spring 9 is arranged between the end of the special-shaped piston 6 and the middle joint 2; The first flow passage 1-1 along the axial direction provided on the pipe wall of the pipe 1 and the second passage 2-1 passing through the axial direction provided on the middle joint 2 are bot...

Embodiment 2

[0064] This embodiment also provides a construction method of an outer flat high-pressure jet grouting device for complex underground coal mine formations, including the following steps:

[0065] a. Construction preparation steps: configure the corresponding drilling fluid according to the properties and characteristics of the destination layer, adjust the performance indicators to meet the requirements; configure the cement slurry with a certain water-cement ratio, and it is required to have fast solidification speed and high solidification strength. characteristic;

[0066] b. Installation steps of the device: Insert the special-shaped piston into the outer pipe of the water, connect the limit spring and the middle joint in sequence, put the quantitative expansion agent into the expansion chamber, connect the elbow to the middle joint and ensure that the central axis of the lower end of the elbow is in the middle of the device as a whole The axes are consistent, and then con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Preload | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com