A Metal-polymer Composite Microstructure Heat Sink Structure for CPU Applications

A technology of composite microstructure and radiator, which is used in instruments, computing, electrical and digital data processing, etc., can solve the problems of poor radiator performance, affecting CPU performance, and high processing costs, to improve thermal conductivity, increase heat dissipation area, improve The effect of the flow situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

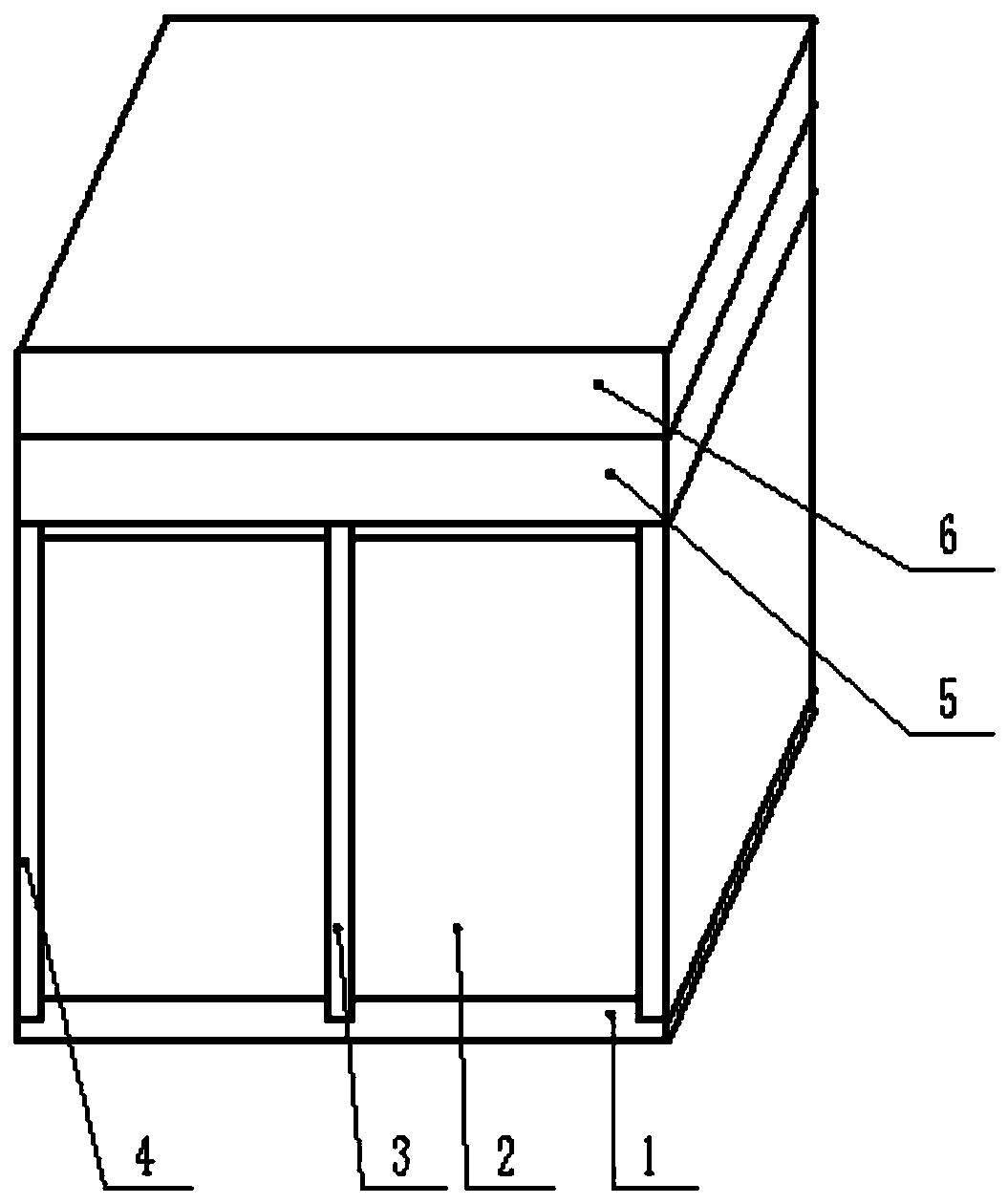

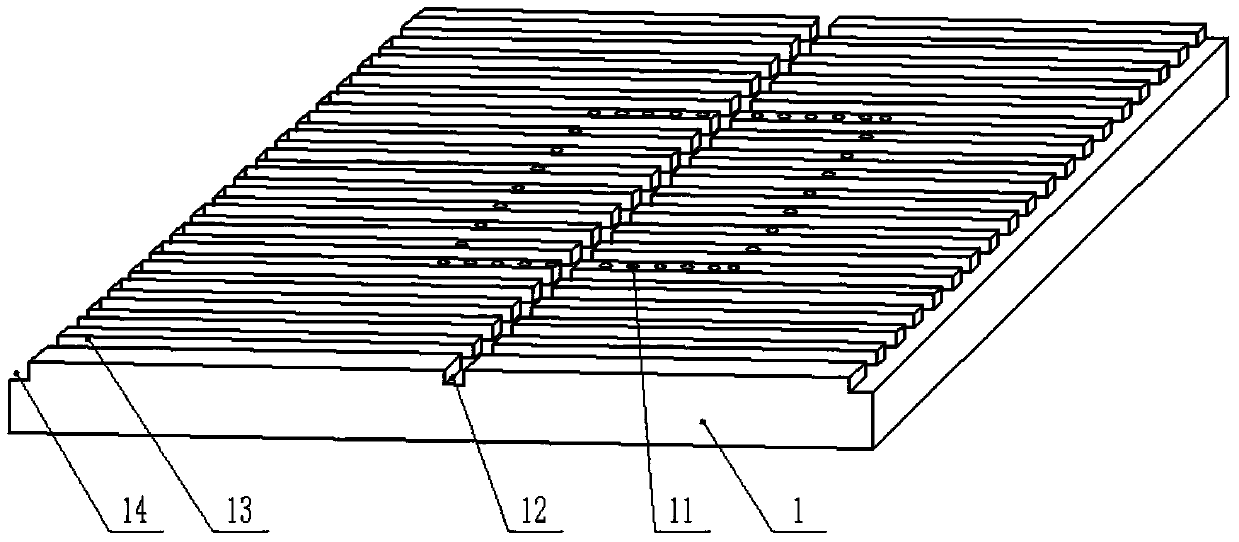

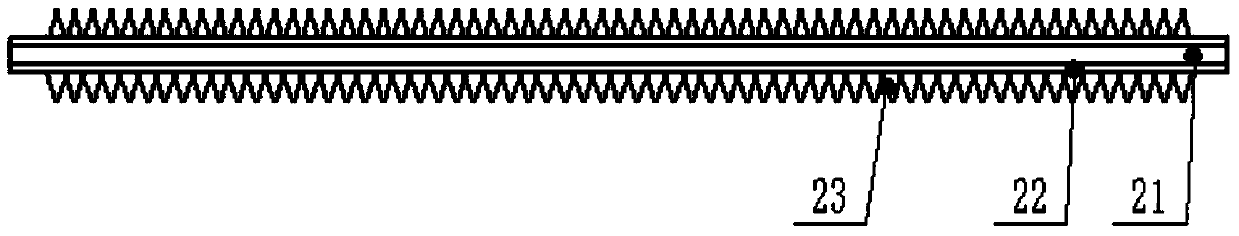

[0026]A CPU-oriented metal-polymer composite microstructure heat sink can be used for cooling the CPU. In this embodiment, the metal base plate 1 is a copper or aluminum cube base plate with a length, width and height of 795 mm. It is provided with multiple Install rectangular slots 13 with microstructured cooling fins, the size of which is 35mm2mmmm; the number of preferential rectangular slots is 32, and there are multiple rectangular slots 14 for installing metal side plates and for installing metal middle plates The rectangular groove 13, the size of the rectangular groove is 9mm3mmmm; a plurality of convection holes 11 on the metal base plate are arranged around the place in direct contact with the CPU, and the diameter of the convection holes 11 on the metal base plate is 5mm, uniformly distributed On a square 3mm larger in size than the CPU. The metal bottom plate 1 is pasted on the CPU through heat-conducting silicone grease, and fixed on the computer motherboard throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com