A multi-channel trigger current testing system and its debugging and testing method

A technology for triggering current and testing system, applied in the direction of using digital measurement technology for measurement, measurement device, measurement of electrical variables, etc., can solve the problem of inability to realize multi-channel long-term sampling experiments, etc., to make up for a single sensor and data acquisition circuit. Inadequate, achieve the effect of optimizing the range and accuracy, and data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

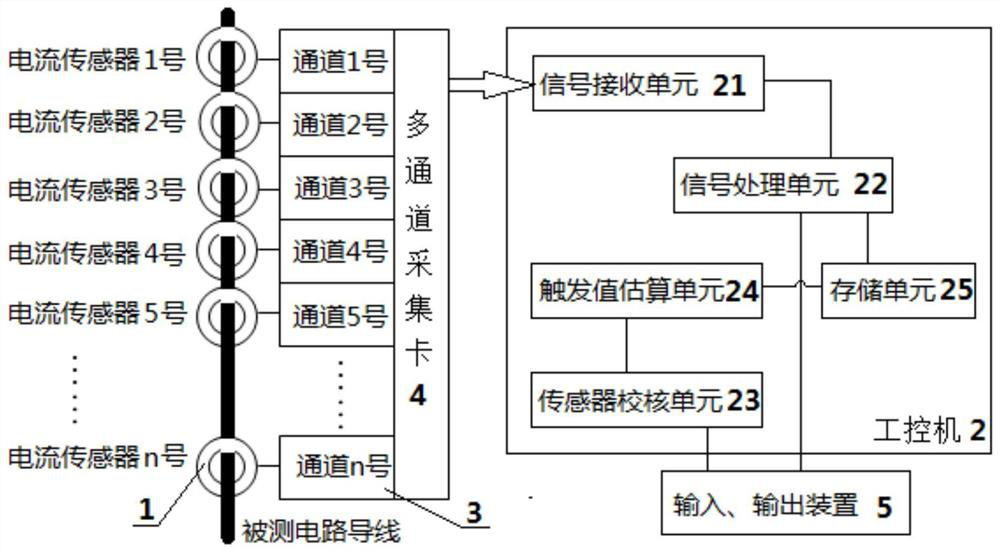

[0062] A multi-channel trigger current testing system includes a current sensor 1 and an industrial computer 2, and the current sensor 1 is connected to the industrial computer 2 for signals; the test system includes a plurality of current sensors 1, and the plurality of current sensors 1 pass through Corresponding sampling channel 3 is connected with multi-channel acquisition card 4 signals, and described multi-channel acquisition card 4 is connected with industrial computer 2 signals, and described industrial computer 2 is connected with input and output device 5 signals; Described current sensor 1 is non-contact type sensor; the industrial computer 2 includes: a signal receiving unit 21, a signal processing unit 22, a sensor checking unit 23, a trigger value estimation unit 24 and a storage unit 25, and the signal receiving unit 21 signal input terminal is connected to a multi-channel acquisition card The signal output end of 4 is connected, and the signal output end of the ...

Embodiment 2

[0071] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0072] The industrial computer 2 is an embedded industrial computer or a PC industrial computer;

[0073] The input and output devices 5 include: a keyboard, a mouse, a display, and a touch display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com