Multifunctional long round water-cooling copper pipe winding device and method

A water-cooled copper tube, multi-functional technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problems of water-cooled transformers, such as larger size, larger size, and narrow installation space, to reduce transformer failure problems , to achieve the effect of precision and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

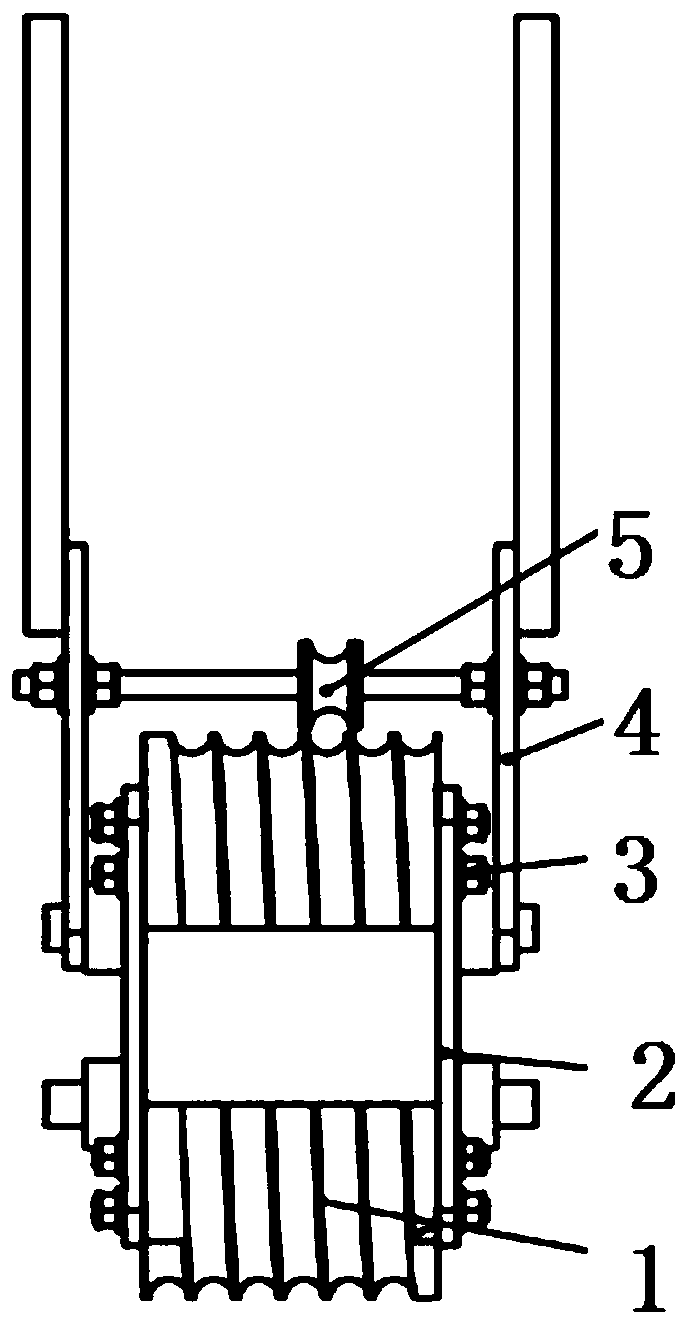

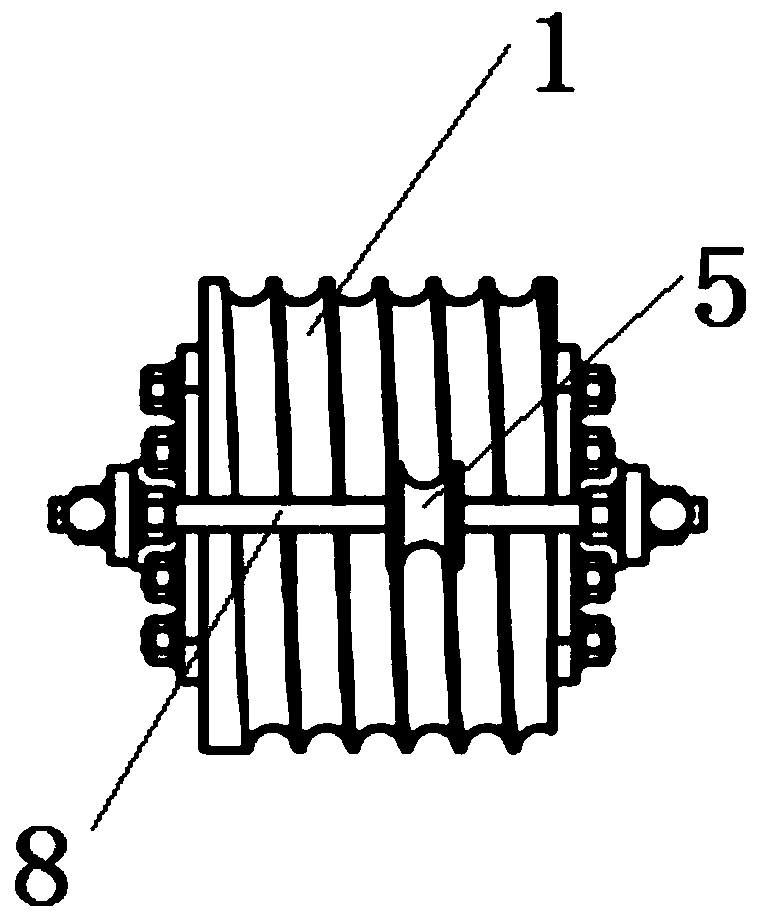

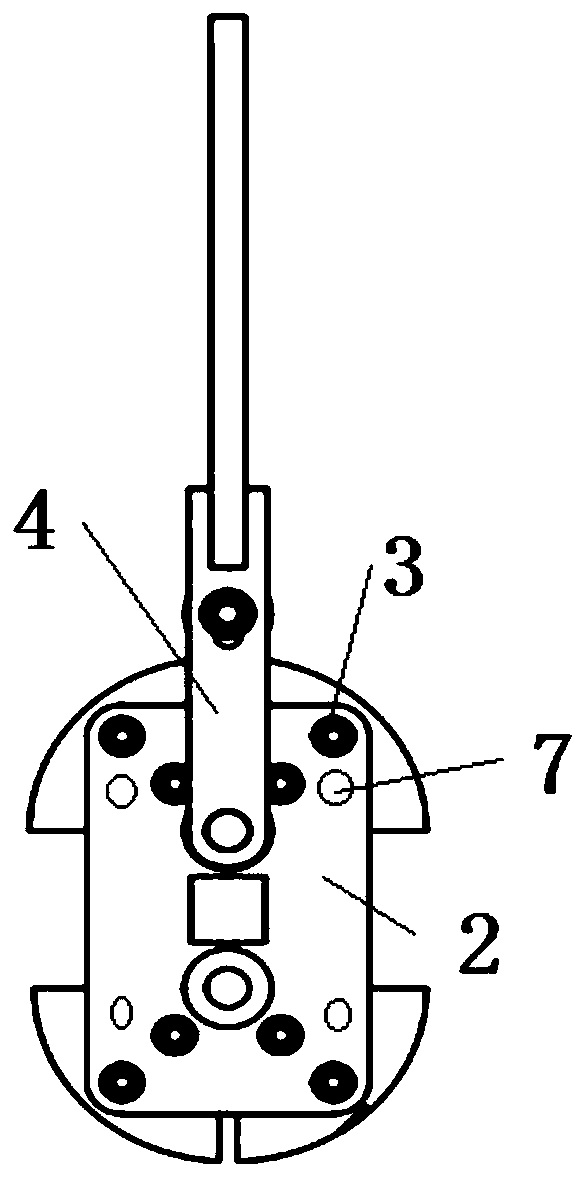

[0026] Such as Figure 1-Figure 6 As shown, the present invention provides a multi-functional oblong water-cooled copper pipe winding device, which is characterized in that: it includes a winding core, and the winding core is composed of four winding core assemblies 6. The 4 winding mold core components 6 are cut in a helical shape by using large round steel finishing, each of the winding mold core 1 components is a quarter of the winding mold core 1, and the 4 winding mold cores The components of the core 1 are tightly connected with the core splint 2 through the clamping screw 3. The center of the core splint 2 is provided with a rotating shaft. Two winding mold core 1 components, two winding mold core 1 components are arranged below, the distance between the upper two winding mold core 1 components and the lower two winding mold core 1 components is at least greater t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap