Plate ceramic membrane filtration performance testing device and testing method

A filtration performance testing, ceramic membrane technology, applied in the field of water treatment, can solve the problems of uneven product quality, inability to track test data in real time, and complicated operation, so as to shorten the sample sending and testing cycle, test data is accurate and reliable, and avoid secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

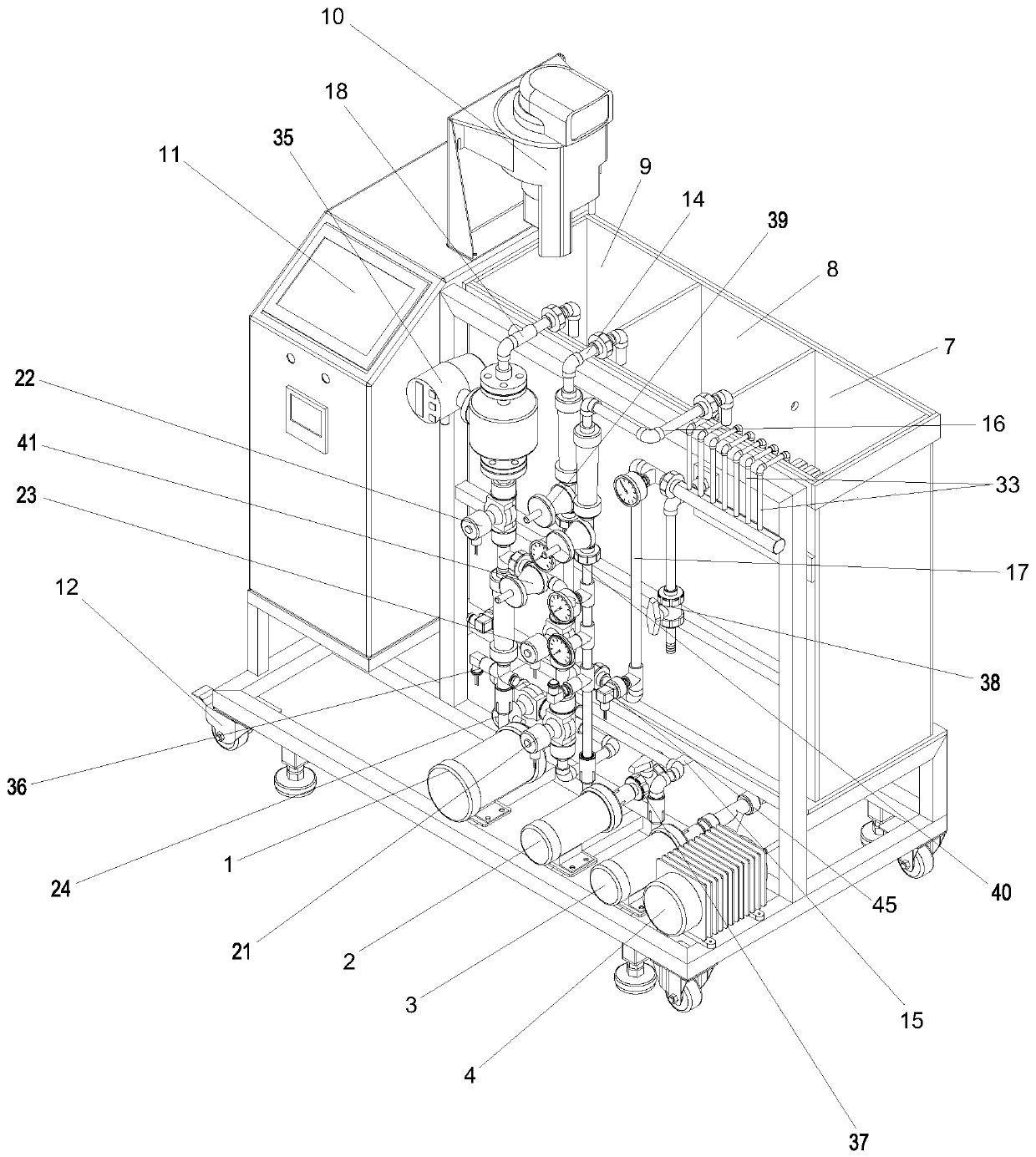

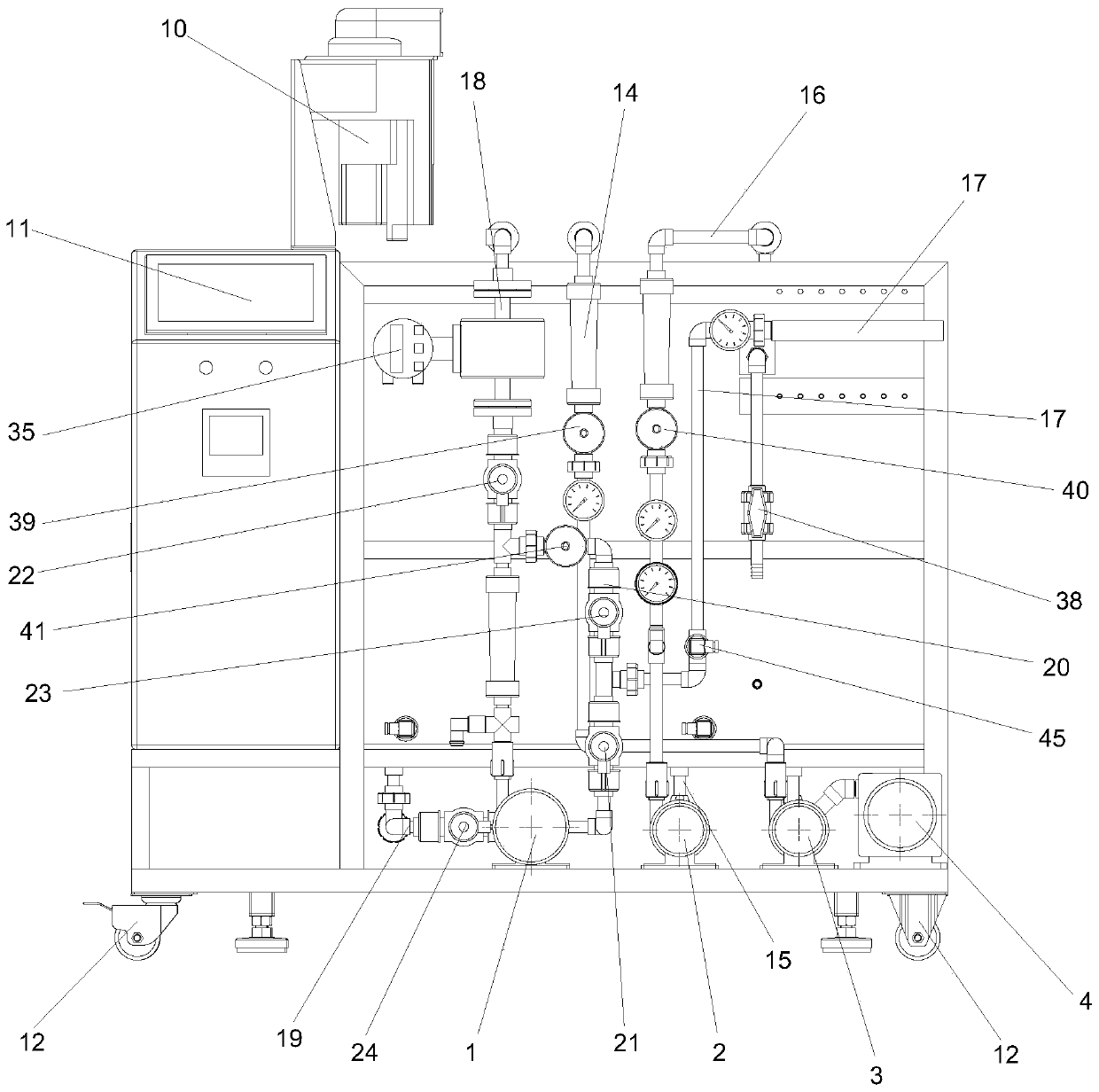

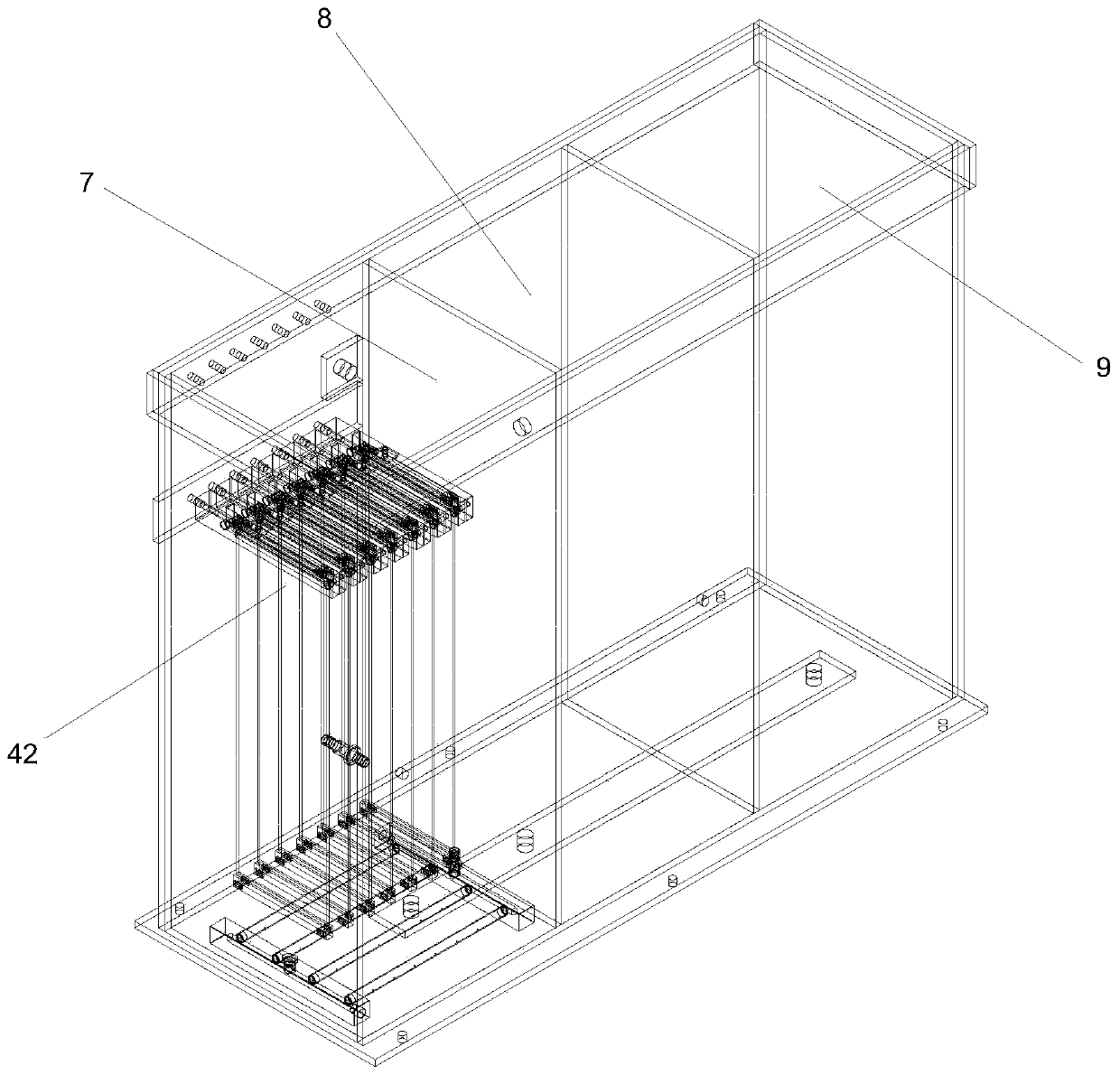

[0033] Such as Figure 1-5 As shown, the flat ceramic membrane filtration performance testing equipment of this embodiment includes a frame and a water production tank 9, a raw water tank 8, a membrane pool 7, a water production pump 1, a water delivery pump 2, a raw water pump 3 and an analyzer 10 arranged on the frame And control device 11, aeration device and universal wheel 12, filter device 42 is arranged in membrane pool 7, raw water pipeline 14 is arranged between raw water pump 3 and raw water tank 8, between the bottom of raw water tank 8 and water transfer pump 2 A sewer pipeline 15 is provided, a water delivery pipeline 16 is provided between the membrane tank 7 and the water delivery pump 2, a first water production pipeline 17 is provided between the membrane tank 7 and the water production pump 1, and the filter device 42 is connected to the first water production pipeline 33 through the membrane tank 7. The water production pipeline 17 is connected, the second w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com