Turning piece cleaning equipment

A technology for cleaning equipment and turning, applied to lighting and heating equipment, cleaning methods and utensils, cleaning methods using liquids, etc., which can solve the problem of puncture wounds, metal shavings stinging users, and inability to completely remove metal shavings from turning parts and other issues to achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

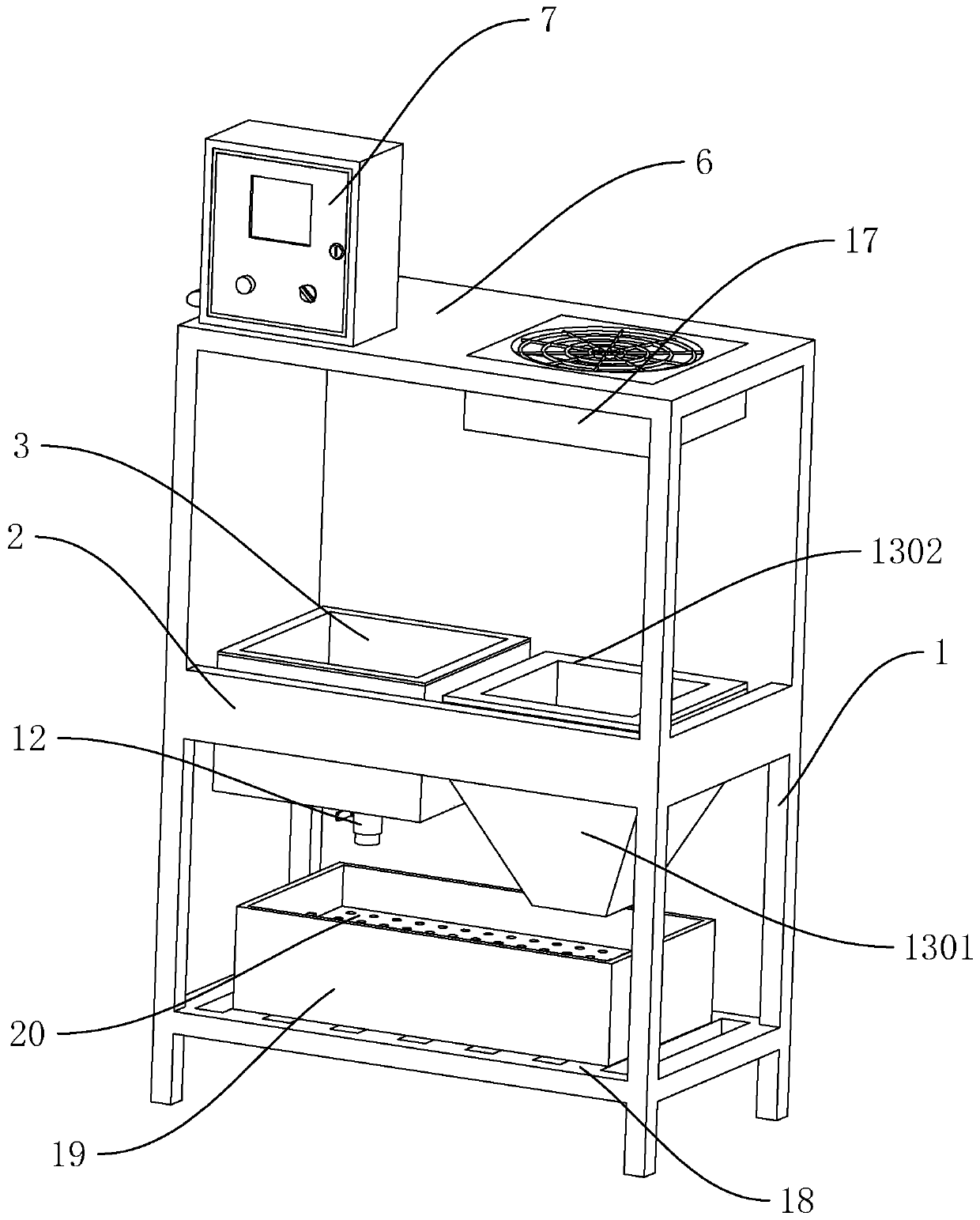

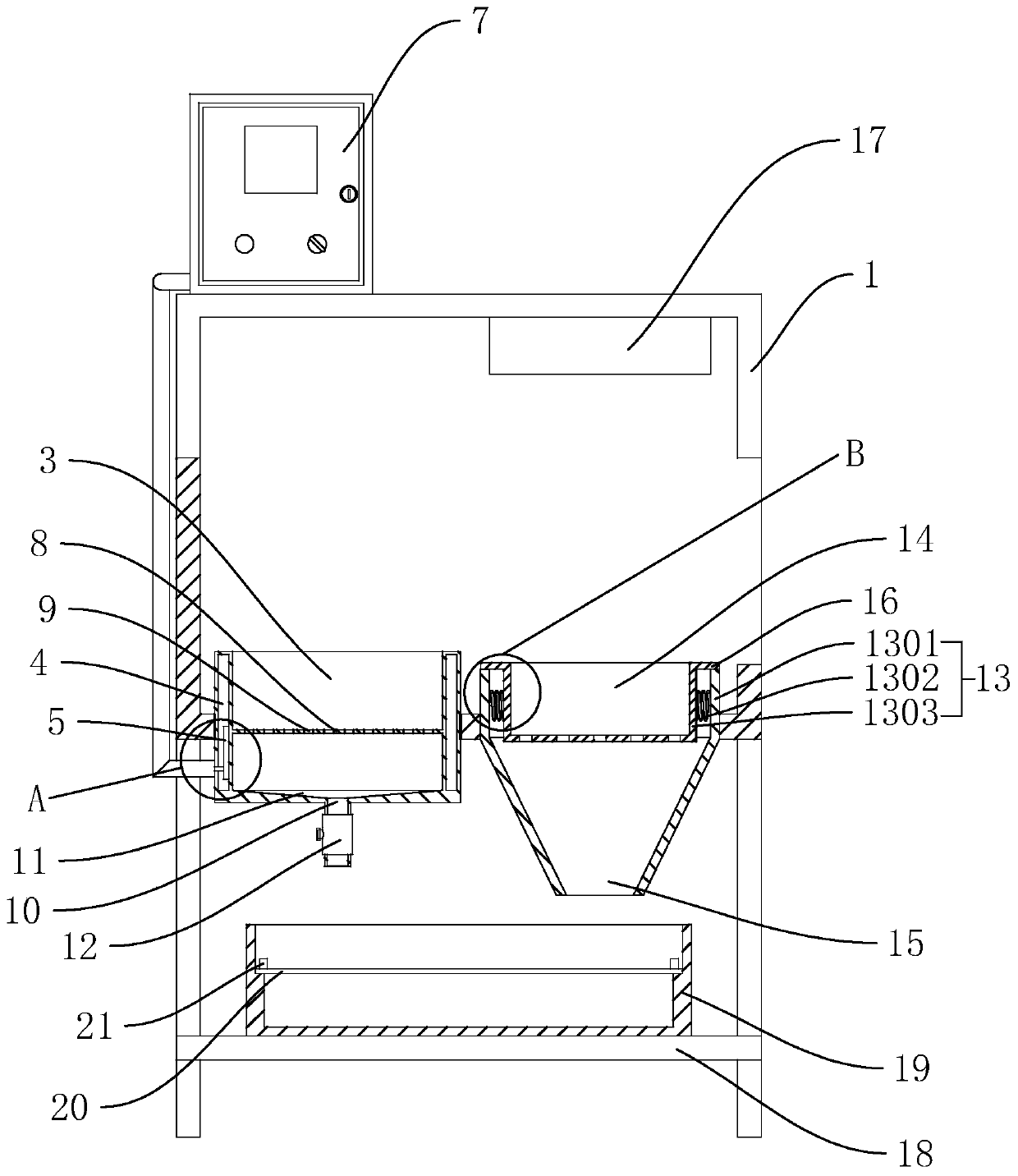

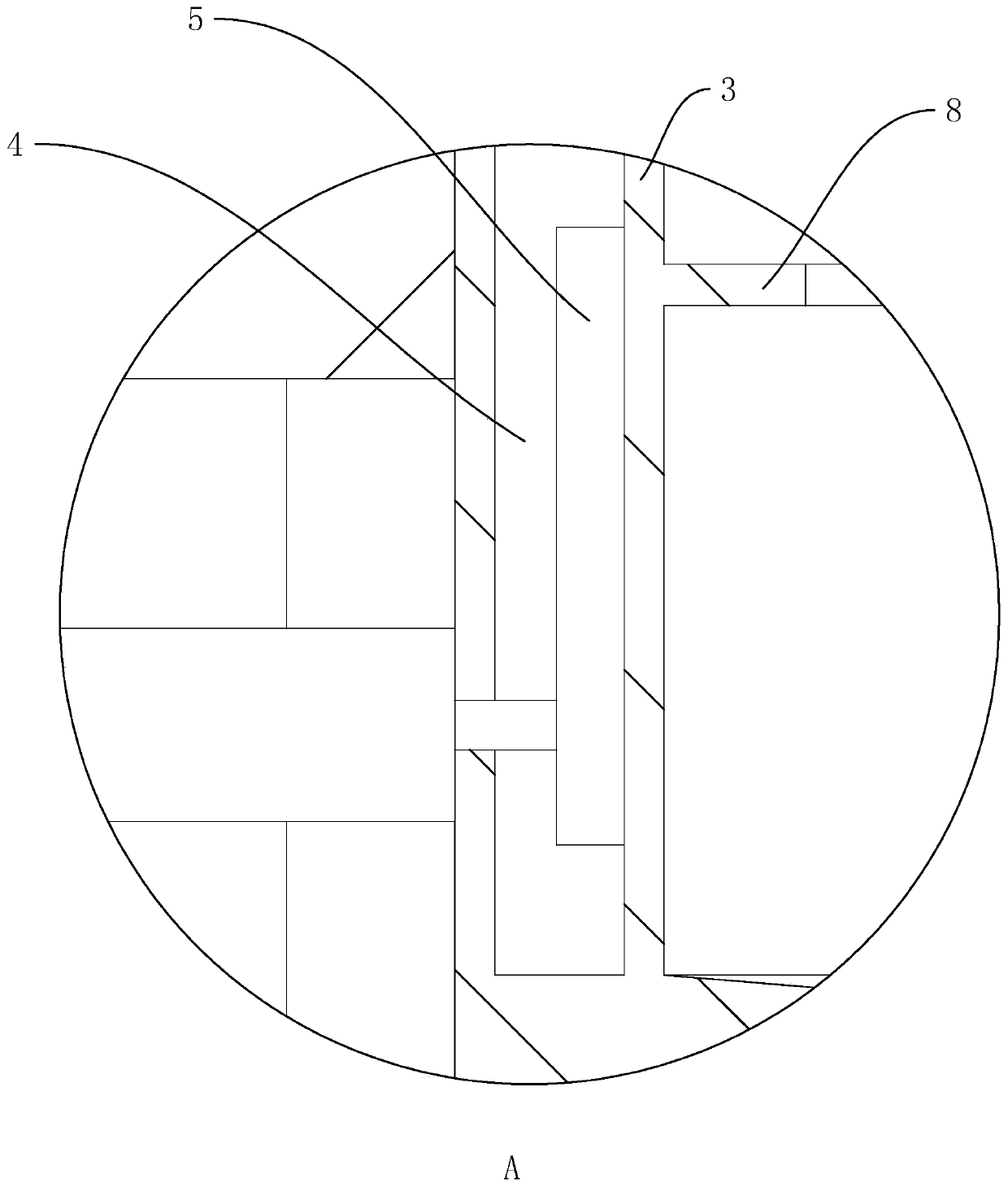

[0039] refer to Figure 1 to Figure 3 , is a kind of turning parts cleaning equipment disclosed by the present invention, comprising a body 1, a cleaning platform 2 is fixed on the body 1, a cleaning pool 3 is placed on the cleaning platform 2, and a cavity 4 is opened on the side wall of the cleaning pool 3, and the cavity A heating device 5 is placed in the 4, and the heating device 5 is preferably an electric heating sheet. The body 1 is fixed with a top plate 6 above the cleaning platform 2, and a control box 7 is placed on the top plate 6. The control box 7 controls the starting and closing of the heating device 5. The heating device 5 is attached to the side of the cavity 4 close to the inner wall of the cleaning pool 3, and the heating device 5 transfers heat to the inner wall of the cleaning pool 3 to heat the cleaning liquid in the cleaning pool 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com