Manufacturing method of oil casing coupling blank

A manufacturing method and oil casing technology, which are applied in the manufacturing field, can solve the problems of difficult rolling of pipes, low efficiency, and low metal yield of coupling finished products, so as to improve metal yield, improve processing efficiency, and facilitate production. the effect of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

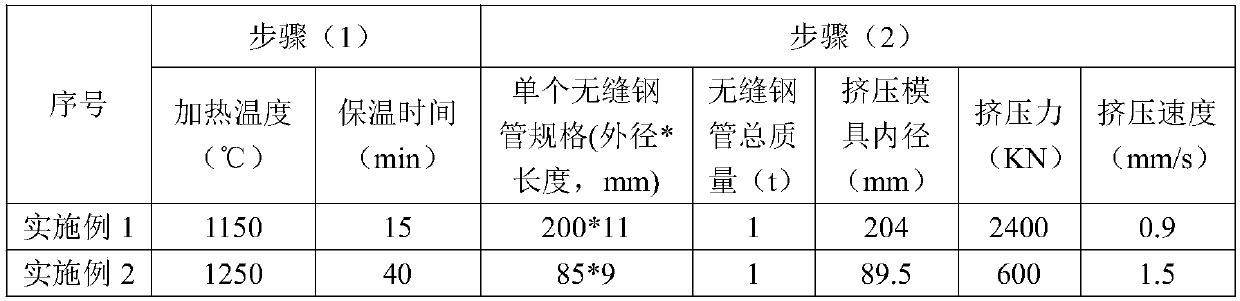

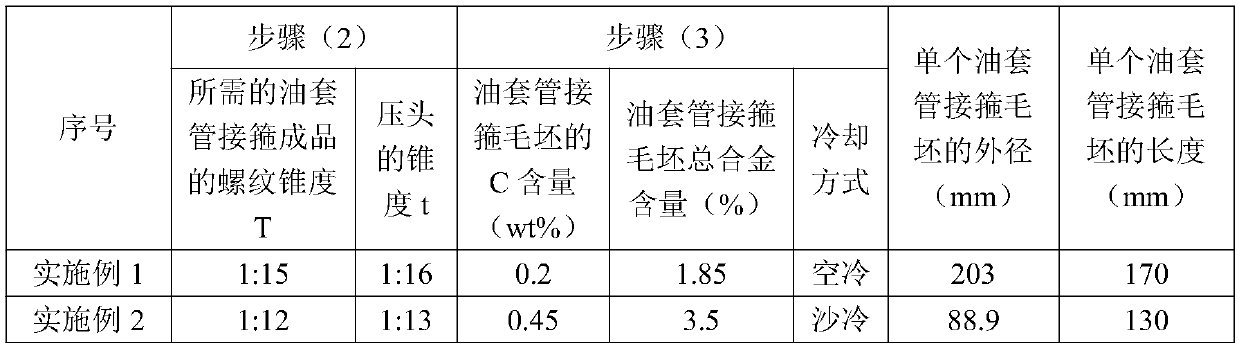

[0036] The oil casing collar blank of Example 1-2 is prepared by the following steps (see Table 1-1 and Table 1-2 for specific process parameters):

[0037] (1) Heat the seamless steel pipe to 1100-1300°C and keep it warm for 10-60 minutes.

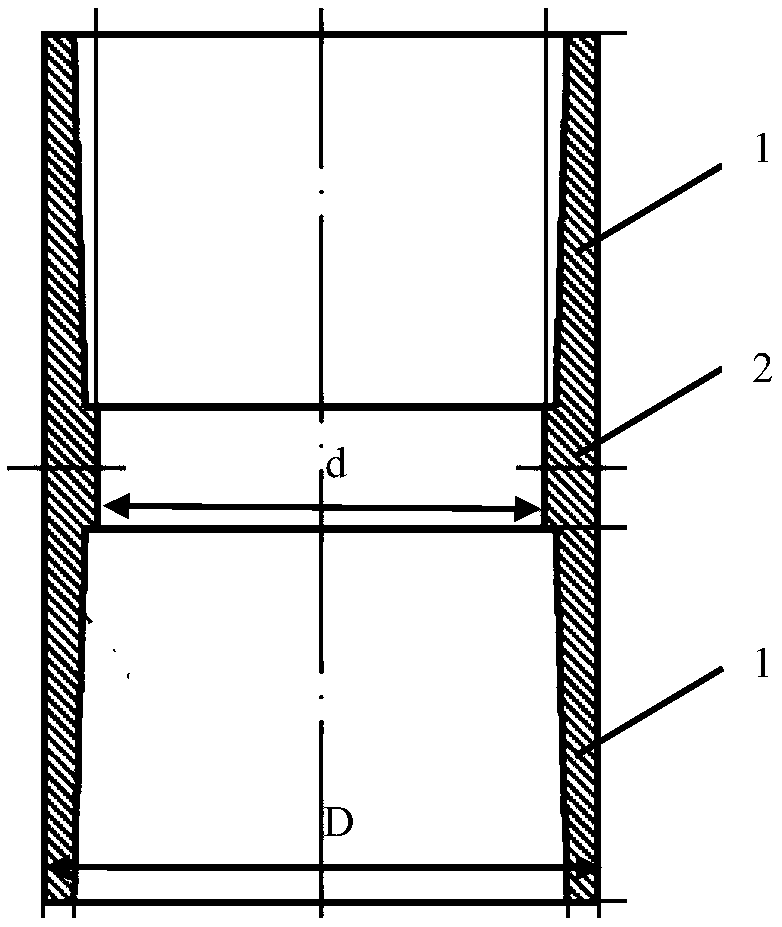

[0038] (2) Place the seamless steel pipe in an extrusion die with a cylindrical inner cavity, and use a pair of indenters to extrude each other from both ends of the seamless steel pipe in the axial direction along the axial direction of the seamless steel pipe. To form two conical coupling blank connection parts and a boss between the two coupling blank connection parts on the inner wall of the seamless steel pipe. Wherein, the extrusion force of the extrusion feed is 400-5000KN, and the extrusion speed of the extrusion feed is 0.2-3mm / s. In addition, the indenter is a cone with a taper. When the required thread taper of the finished oil casing coupling is T≤1:15, the taper t of the indenter needs to meet 0.5T 1:15, the taper t of the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com