Automatic routing of wire harness of electrical system by means of two force control robots

A robot and wire laying technology, applied in general control systems, control/regulation systems, manufacturing wiring harnesses, etc., can solve problems such as inability to introduce, broken wires, and single metal wires, so as to avoid loop formation, avoid breakage, The Effect of Complexity Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

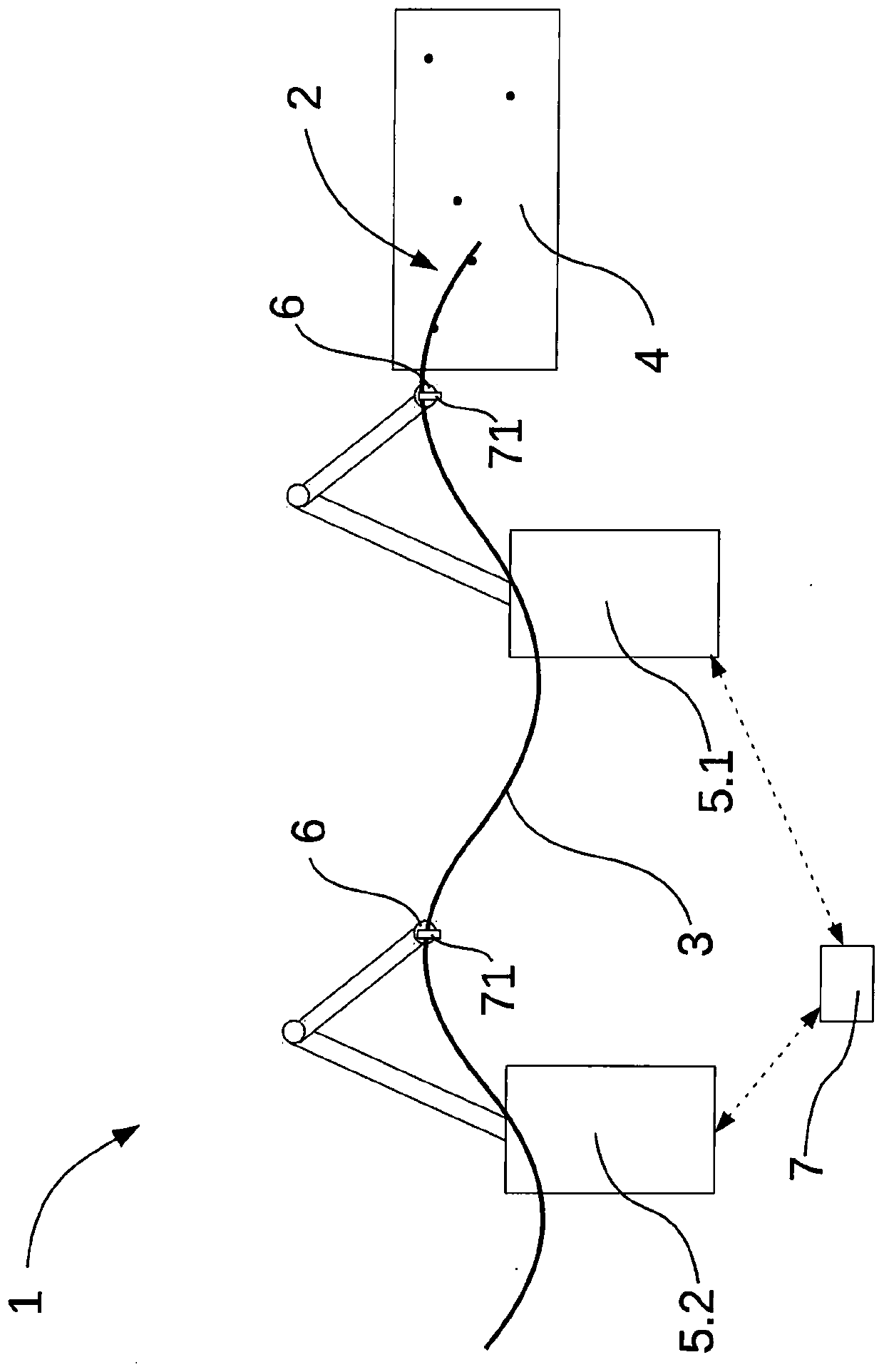

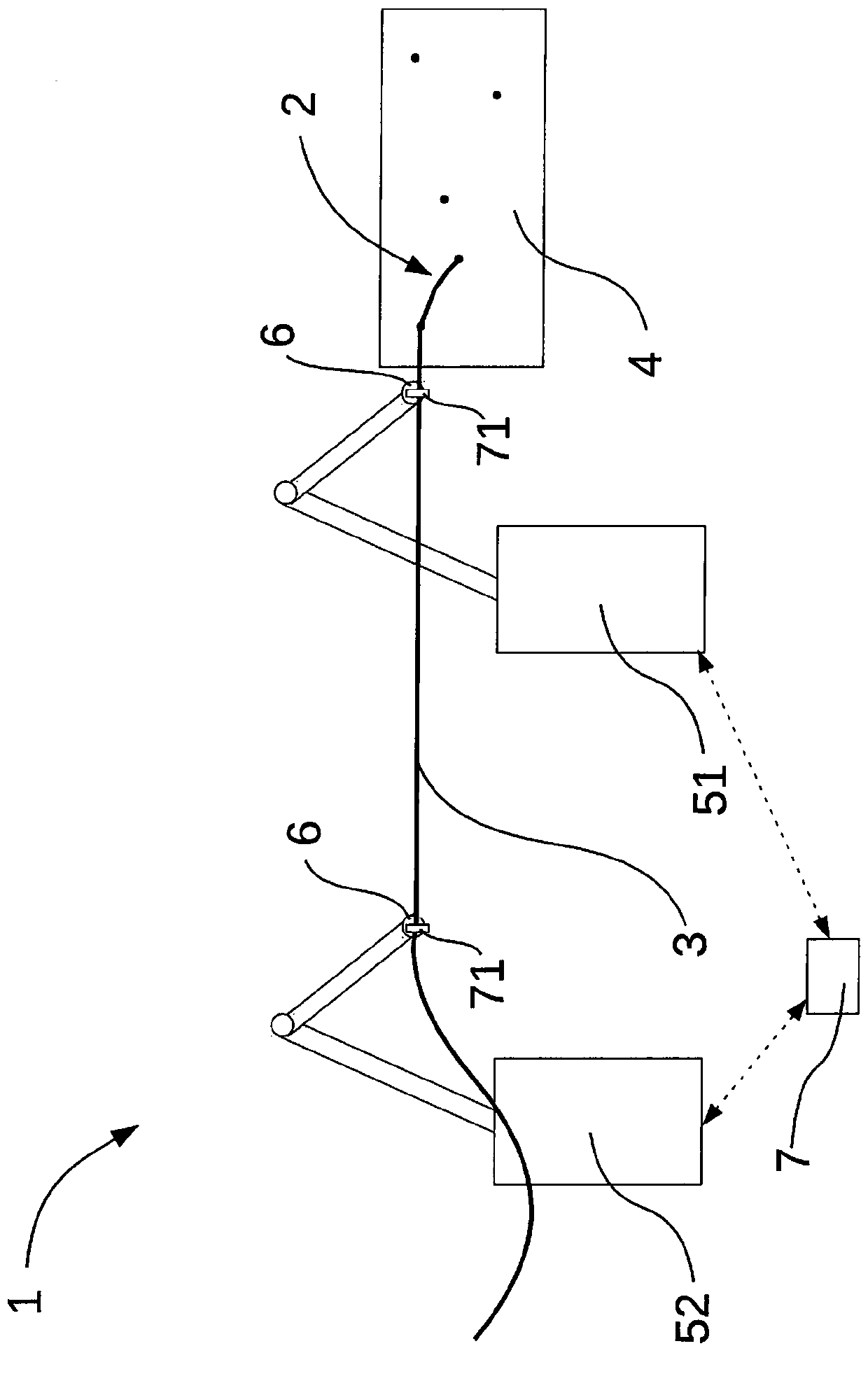

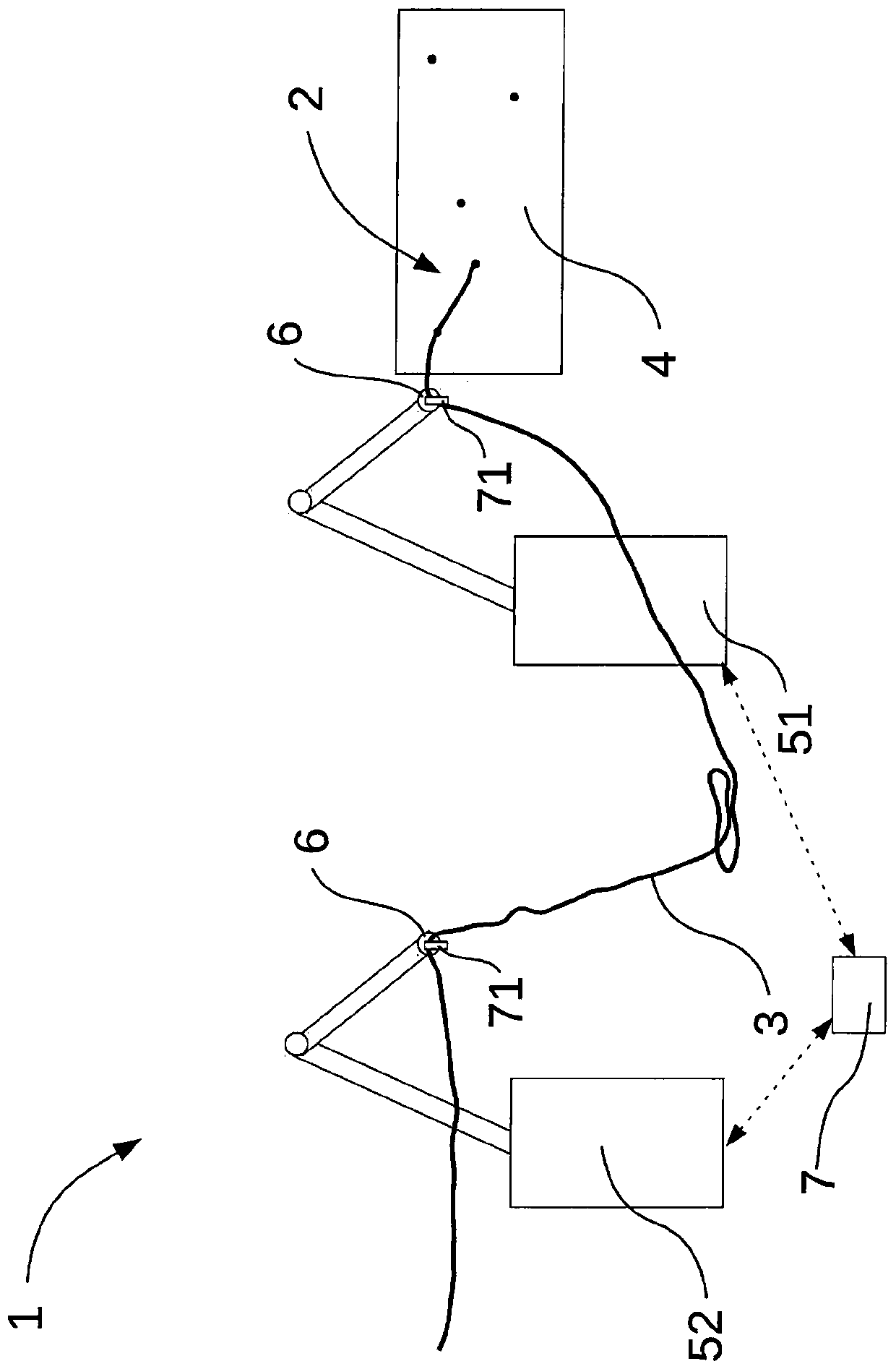

[0028] The invention is referenced below Figure 1 to 3 The description is based on exemplary embodiments, in which the same reference numerals indicate the same structural features and / or functional features.

[0029] figure 1 A schematic diagram of the wire laying system 1 for manufacturing the wire harness 2 in normal operation is shown, and the wire harness is composed of a plurality of cables and / or wires 3. The wire laying system 1 includes two robots 5.1, 5.2, which are assigned different control levels in the system. The robots 5.1, 5.2 are configured to have a grasping element 6 for grasping at least one electric wire 3 of the wire harness 2 for laying the electric wire 3 on the cable mold base plate 4.

[0030] The wire laying system 1 also has a common hierarchical control device 7, which controls the simultaneous movement and simultaneous grabbing of the grabbing elements 6 of the robots 5.1 and 5.2 based on the detected operating data during simultaneous wire processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com