UHPFRC (ultra high performance fiber reinforcement concrete) assembling type road protecting wall and construction method

A protective wall and assembly technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problem of affecting the impact resistance of the protective fence, affecting the practicability, safety, reliability and durability of the protective wall, and the impact of the protective wall. and other problems, to achieve the effect of superior absorption of impact energy, solving the problem of road greening, and strengthening the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

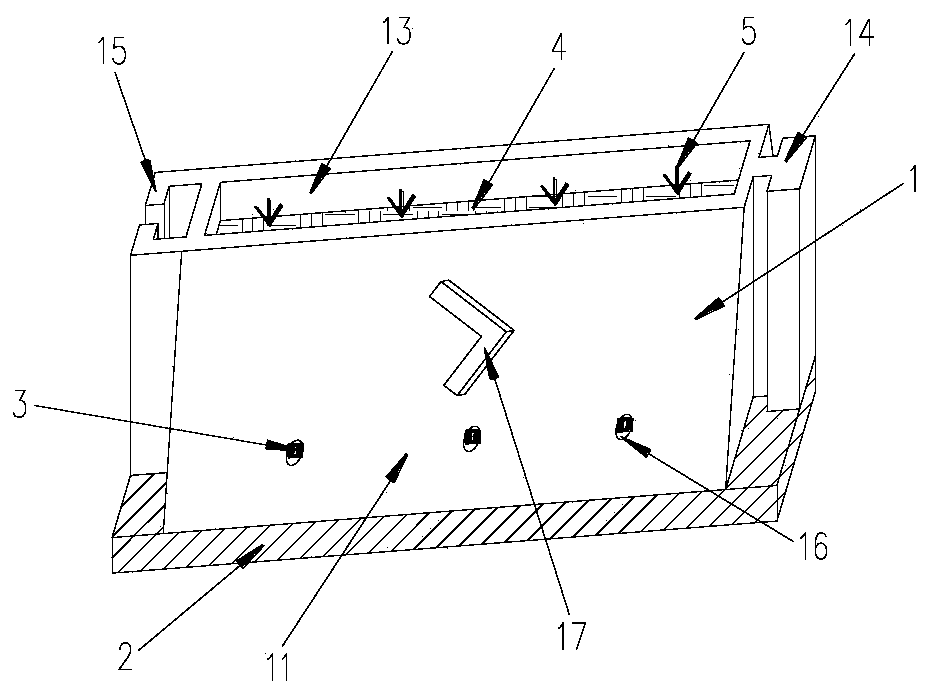

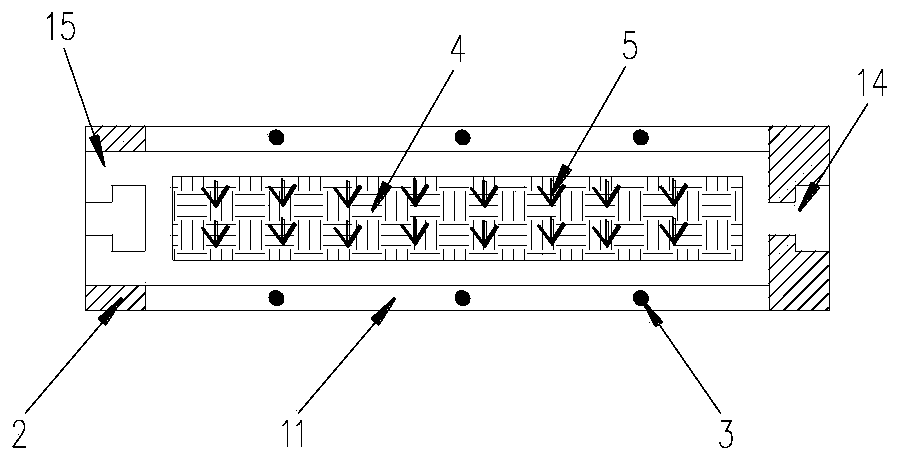

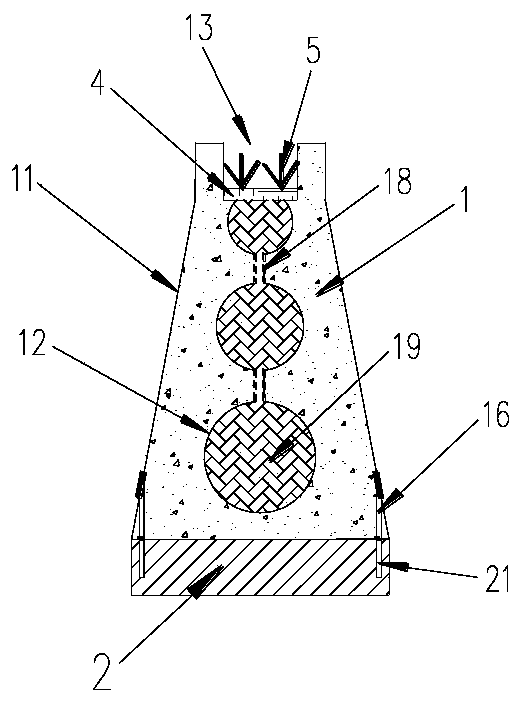

[0042] refer to Figure 1 to Figure 8 , for the UHPFRC prefabricated road protective wall set in the center of the road, including UHPFRC protective wall 1, strip foundation 2, bolts 3, planting soil 4 and green plants 5; where UHPFRC protective wall 1 includes UHPFRC wall side 11, T-shaped connection Part 14, C-shaped connector 15, greening groove 13, embedded hole 12, drainage channel 18, anchor hole 16, L-shaped reflective strip 17; Large; T-shaped connectors 14 and C-shaped connectors 15 are arranged at both ends of the UHPFRC protective wall 1, and the T-shaped connector 14 at the end of the UHPFRC protective wall 1 is implanted into the C-shaped connector 15 to realize the UHPFRC protective wall 1 is embedded and connected; the greening groove 13 is arranged on the top of the UHPFRC protective wall 1; the UHPFRC protective wall 1 is provided with three embedded holes 12, and the top of the last embedded hole 12 is connected with the greening groove 13, which can be autom...

Embodiment 2

[0061] refer to Figure 1 to Figure 8 , for the UHPFRC prefabricated road protective wall set on the side of the road, including UHPFRC protective wall 1, strip foundation 2, bolt 3, planting soil 4 and green plants 5; where UHPFRC protective wall 1 includes UHPFRC wall side 11, T-shaped Connecting piece 14, C-shaped connecting piece 15, greening groove 13, embedded hole 12, drainage channel 18, anchor hole 16, L-shaped reflective strip 17; The lower part is large; the T-shaped connector 14 and the C-shaped connector 15 are arranged at both ends of the UHPFRC protective wall 1, and the T-shaped connector 14 at the end of the UHPFRC protective wall 1 is implanted into the C-shaped connector 15 to realize UHPFRC protection The embedded connection of the wall 1; the green groove 13 is arranged on the top of the UHPFRC protective wall 1; the UHPFRC protective wall 1 is provided with three embedded holes 12, and the top of the uppermost embedded hole 12 is connected with the green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com