Heat-insulating multi-layer pipe for superconducting power transmission and laying method thereof

A multi-layer tube and superconducting technology, applied in the usage of superconductor elements, superconducting devices, pipeline laying and maintenance, etc., can solve the problems of breakage of separators and insufficient thermal insulation, and achieve excellent thermal insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, a method for implementing the present invention will be specifically described. In addition, the following description shows preferable embodiment of this invention, and this invention is not limited at all by the following description.

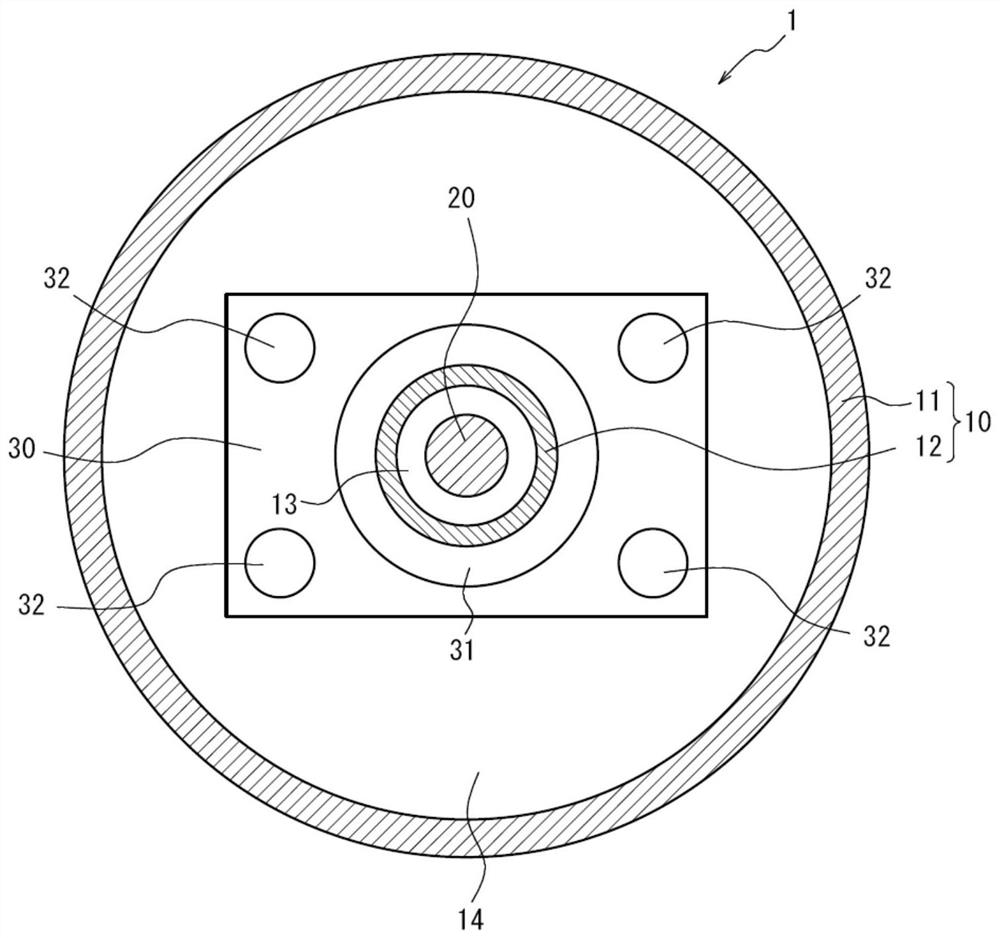

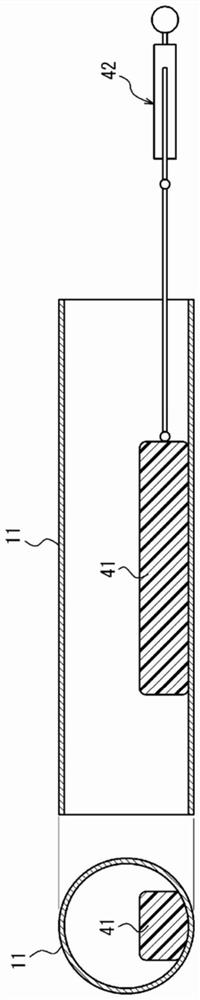

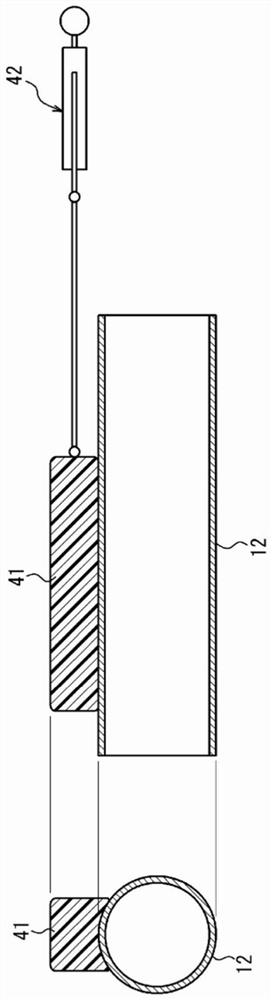

[0039] The heat-insulating multilayer tube for superconducting power transmission according to the present invention includes a superconducting cable, a multilayer tube for accommodating the superconducting cable, and a plurality of spacers. Hereinafter, the structure of each part mentioned above is demonstrated.

[0040] [Superconducting cable]

[0041] Any superconducting cable can be used as the superconducting cable as long as it can be used for superconducting power transmission. An example of a suitably usable superconducting cable includes a superconducting cable having a core material (former, former) made of metal such as copper, an insulating layer, and a conductor made of a superconducting material. Any superconduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com