Baking tray for food processing baking machine

A technology for food processing and baking machines, applied in the direction of baking plates/tables, etc., can solve the problems of uneven distribution of water vapor, food easily sticking to the bottom of the baking plate, and the shape of baked food is damaged, and achieves easy access and placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

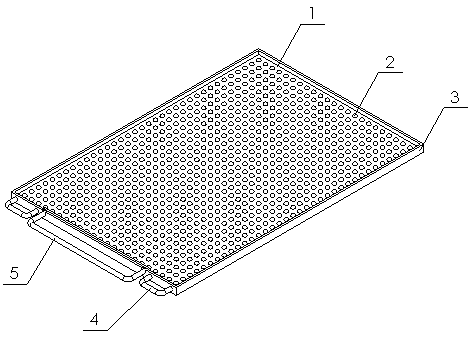

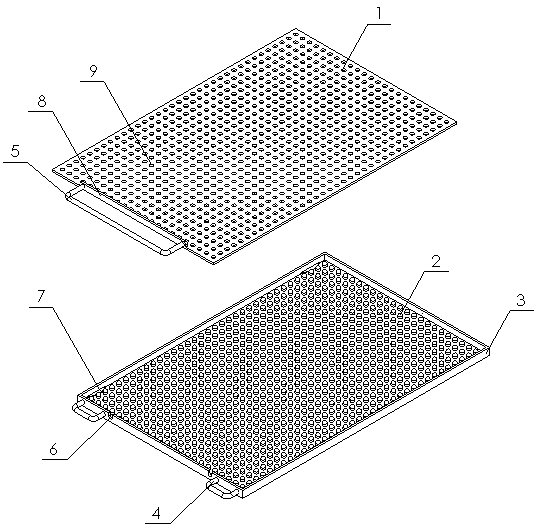

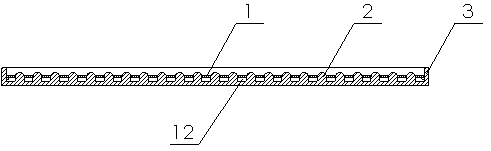

[0017] A baking tray for a food processing and baking machine of the present invention is achieved in the following way: a baking tray for a food processing and baking machine of the present invention consists of an inner baking tray (1), a supporting column point (2), an outer baking tray ( 3), composed of outer handle (4), inner handle (5), card slot (6), limit plate (7), connecting plate (8), through hole (9) and water storage chamber (12), the outer grill There are four limit plates (7) on the inner wall of the tray (3), and the four limit plates (7) are respectively close to the four corners of the outer baking pan (3), and the limit plates (7) The width decreases from the middle to both ends, the inner baking tray (1) is placed in the outer baking tray (3), the inner baking tray (1) is placed on four limiting plates (7), and multiple support columns The point (2) is placed at the bottom of the outer baking pan (3), and a plurality of the support column points (2) are dis...

Embodiment 2

[0021] The difference between this embodiment and Embodiment 1 is: the support column point (2) is additionally provided with a socket (11), the rubber column (10) is inserted into the socket (11), and the rubber column (10) ) is made of food-grade high-temperature resistant silicone rubber; when used, it further reduces the stickiness of the support column point (2) to food, and the baking effect is good;

[0022] The four limiting plates (7) are designed to be close to the four corners of the outer baking tray (3), which can limit the inner baking tray (1), and are distributed at the four corners to the inner baking tray ( 1) The support is relatively stable when supported;

[0023] The design of the water storage cavity (12) formed between the inner baking pan (1) and the outer baking pan (3) can place water during baking to increase the moisture during baking and avoid overdrying during baking;

[0024] The design of a plurality of support column points (2) distributed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com