Method for extracting red ginseng saponin

An extraction method and technology of ginsenosides, applied in the field of extraction of red ginseng saponins, can solve the problems of long extraction time, low extraction rate, high extraction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

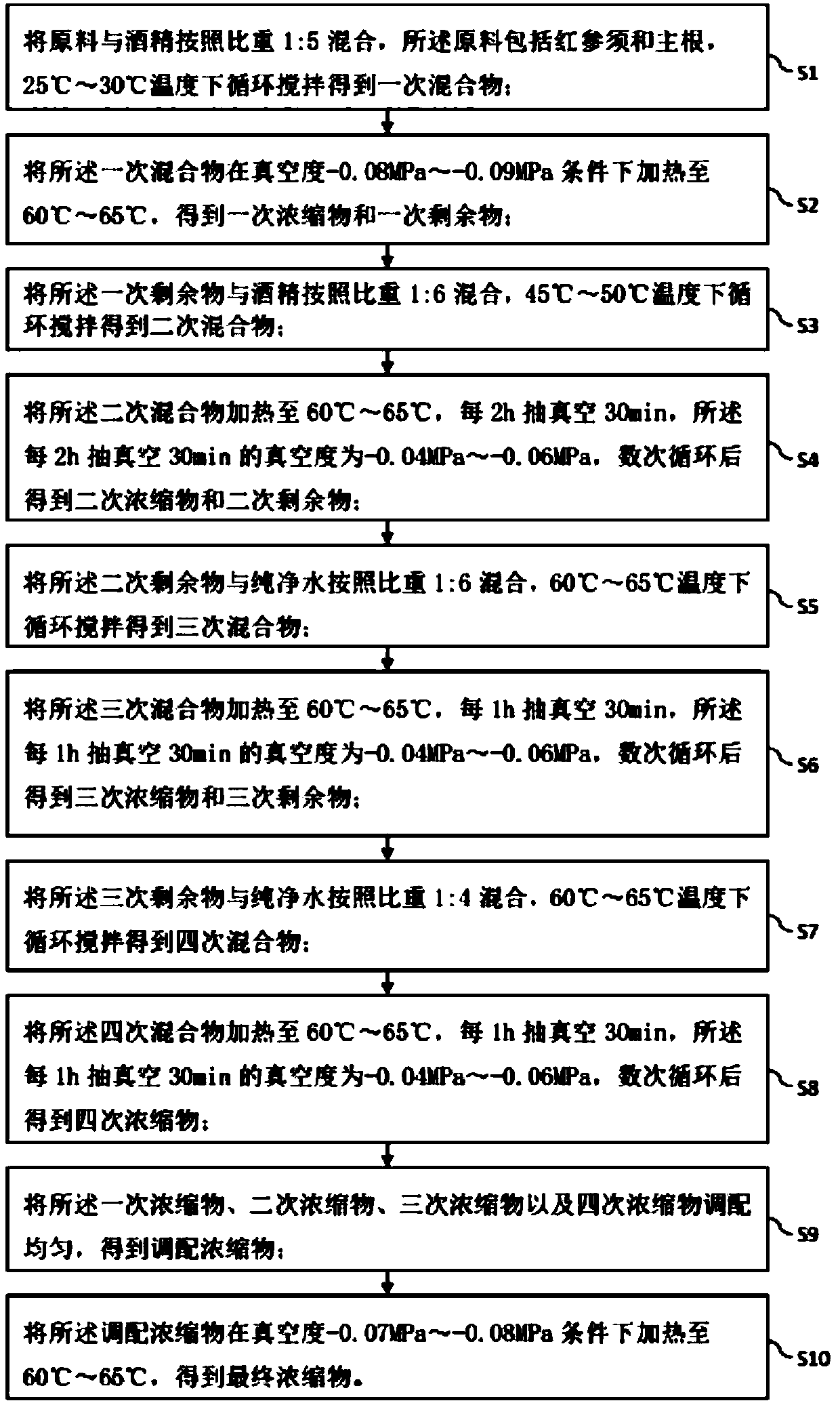

Image

Examples

Embodiment 1

[0042] Step S1, primary extraction: mix the raw materials with alcohol according to the ratio of 1:5, the raw materials include red ginseng whiskers and main roots, and circulate and stir at a temperature of 25°C to 30°C to obtain a primary mixture;

[0043] Step S2, primary concentration: heating the primary mixture to 60° C. to 65° C. under a vacuum of -0.08 MPa to -0.09 MPa to obtain a primary concentrate and a primary residue;

[0044] Step S3, secondary extraction: mix the primary residue with alcohol according to the ratio of 1:6, and circulate and stir at a temperature of 45°C to 50°C to obtain a secondary mixture;

[0045] Step S4, secondary concentration: heat the secondary mixture to 60°C-65°C, vacuumize for 30min every 2h, and the vacuum degree of vacuumize for 30min every 2h is -0.04MPa~-0.06MPa, after several cycles Obtain secondary concentrate and secondary residue;

[0046] Step S5, third extraction: mix the secondary residue with purified water according to th...

Embodiment 2

[0054] Step S1, primary extraction: mix the raw materials with alcohol according to the ratio of 1:5, the raw materials include red ginseng whiskers and main roots, and circulate and stir at a temperature of 25°C to 30°C to obtain a primary mixture;

[0055] Step S2, primary concentration: heating the primary mixture to 60° C. to 65° C. under a vacuum of -0.08 MPa to -0.09 MPa to obtain a primary concentrate and a primary residue;

[0056] Step S3, secondary extraction: mix the primary residue with alcohol according to the ratio of 1:6, and circulate and stir at a temperature of 45°C to 50°C to obtain a secondary mixture;

[0057] Step S4, secondary concentration: heat the secondary mixture to 60°C-65°C, vacuumize for 30min every 2h, and the vacuum degree of vacuumize for 30min every 2h is -0.04MPa~-0.06MPa, after several cycles Obtain secondary concentrate and secondary residue;

[0058] Step S5, third extraction: mix the secondary residue with purified water according to th...

Embodiment 3

[0067] Step S1, primary extraction: mix the raw materials with alcohol according to the ratio of 1:5, the raw materials include red ginseng whiskers and main roots, and circulate and stir at a temperature of 25°C to 30°C to obtain a primary mixture;

[0068] Step S2, primary concentration: heating the primary mixture to 60° C. to 65° C. under a vacuum of -0.08 MPa to -0.09 MPa to obtain a primary concentrate and a primary residue;

[0069] Step S3, secondary extraction: mix the primary residue with alcohol according to the ratio of 1:6, and circulate and stir at a temperature of 45°C to 50°C to obtain a secondary mixture;

[0070] Step S4, secondary concentration: heat the secondary mixture to 60°C-65°C, vacuumize for 30min every 2h, and the vacuum degree of vacuumize for 30min every 2h is -0.04MPa~-0.06MPa, after several cycles Obtain secondary concentrate and secondary residue;

[0071] Step S5, third extraction: mix the secondary residue with purified water according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com