Automatic tobacco essence batching device

A technology of automatic ingredients and tobacco flavor, applied in the direction of mixer accessories, dissolving, mixer, etc., can solve the problems of inaccurate proportion matching, weight deviation, affecting the effect of tobacco flavor blending finished products, etc., and achieve the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to more clearly illustrate the embodiments of the present invention and / or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations. In addition, the affiliation related to the orientation only indicates the relative positional relationship between the components, not the absolute positional relationship.

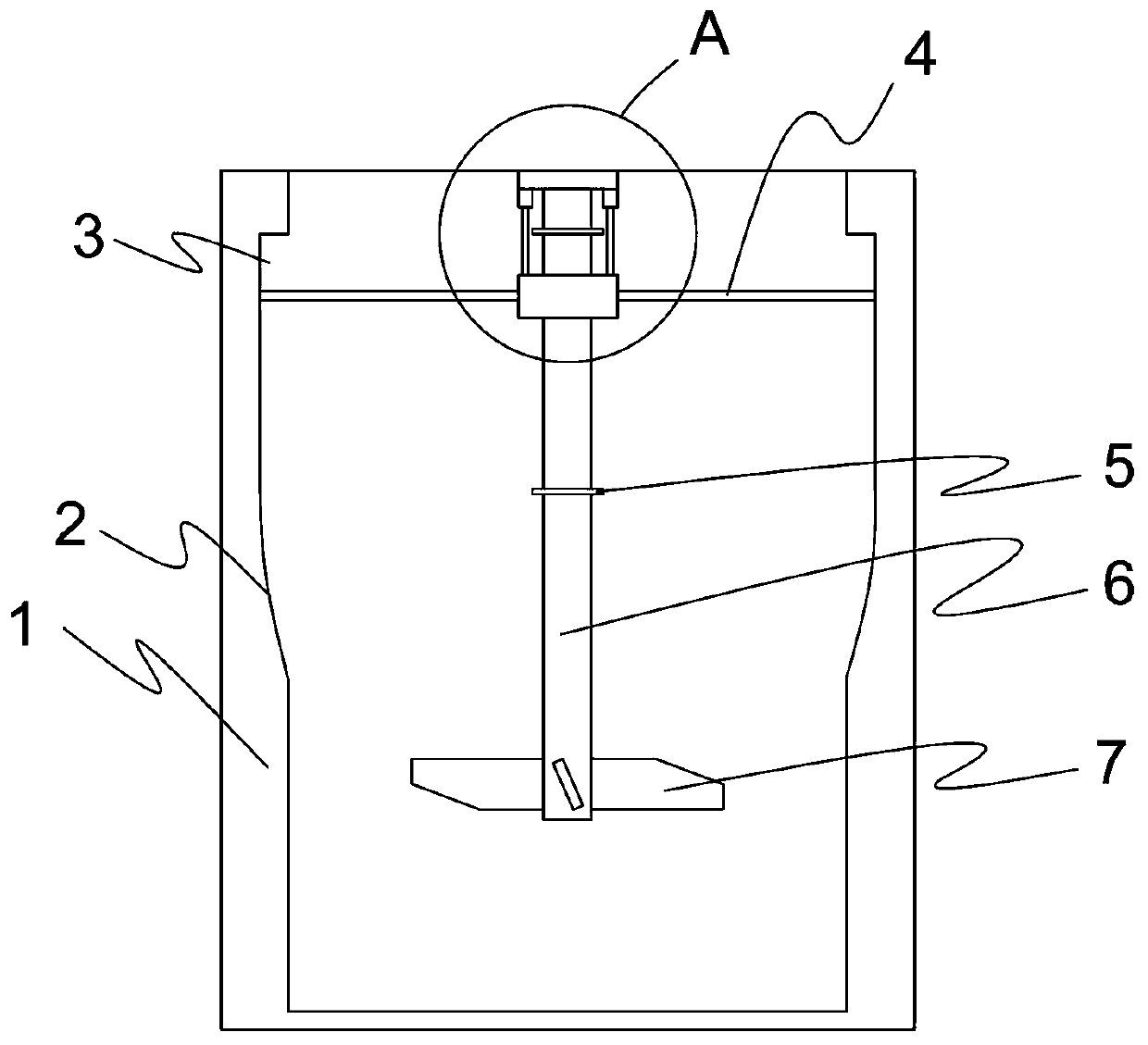

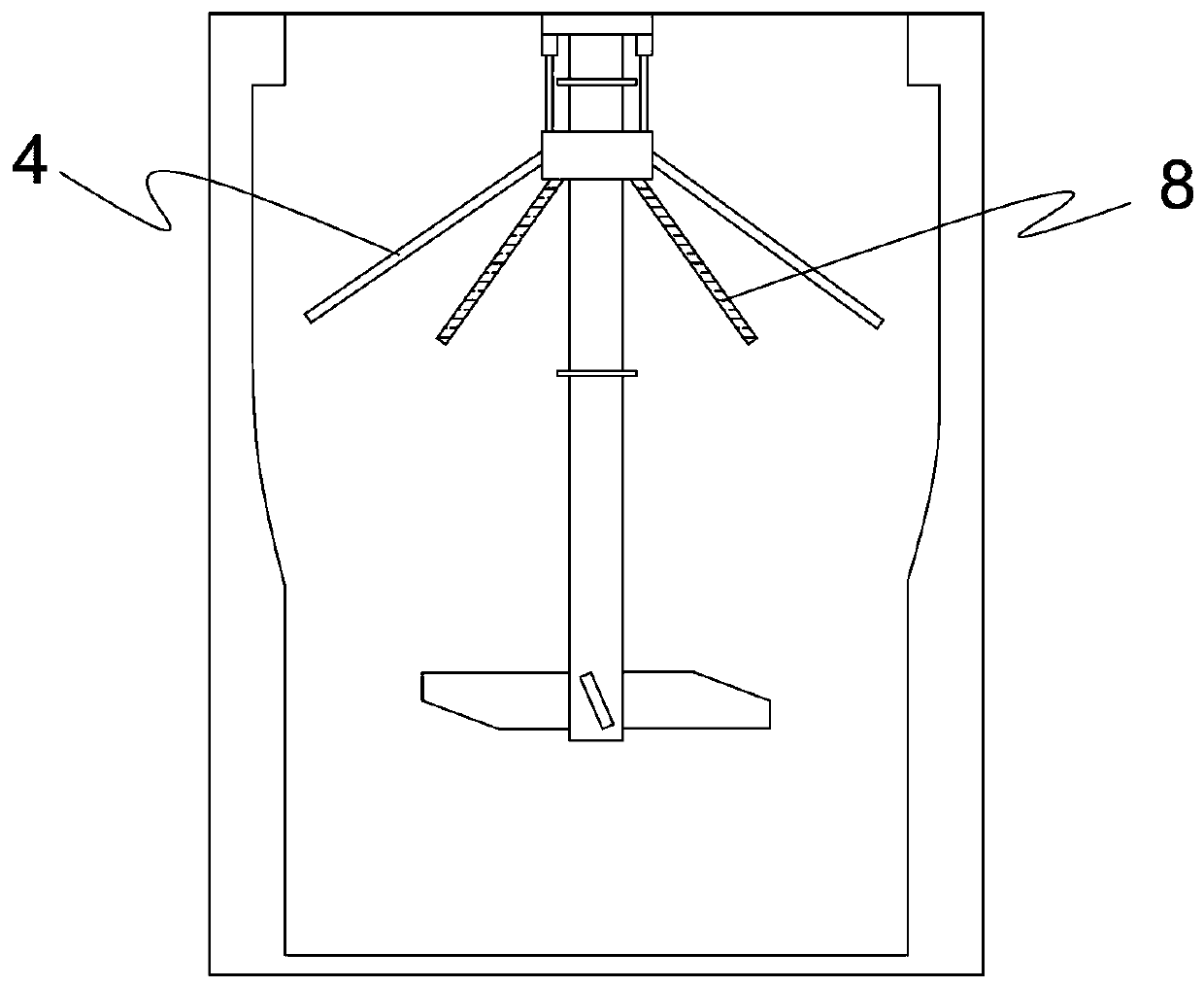

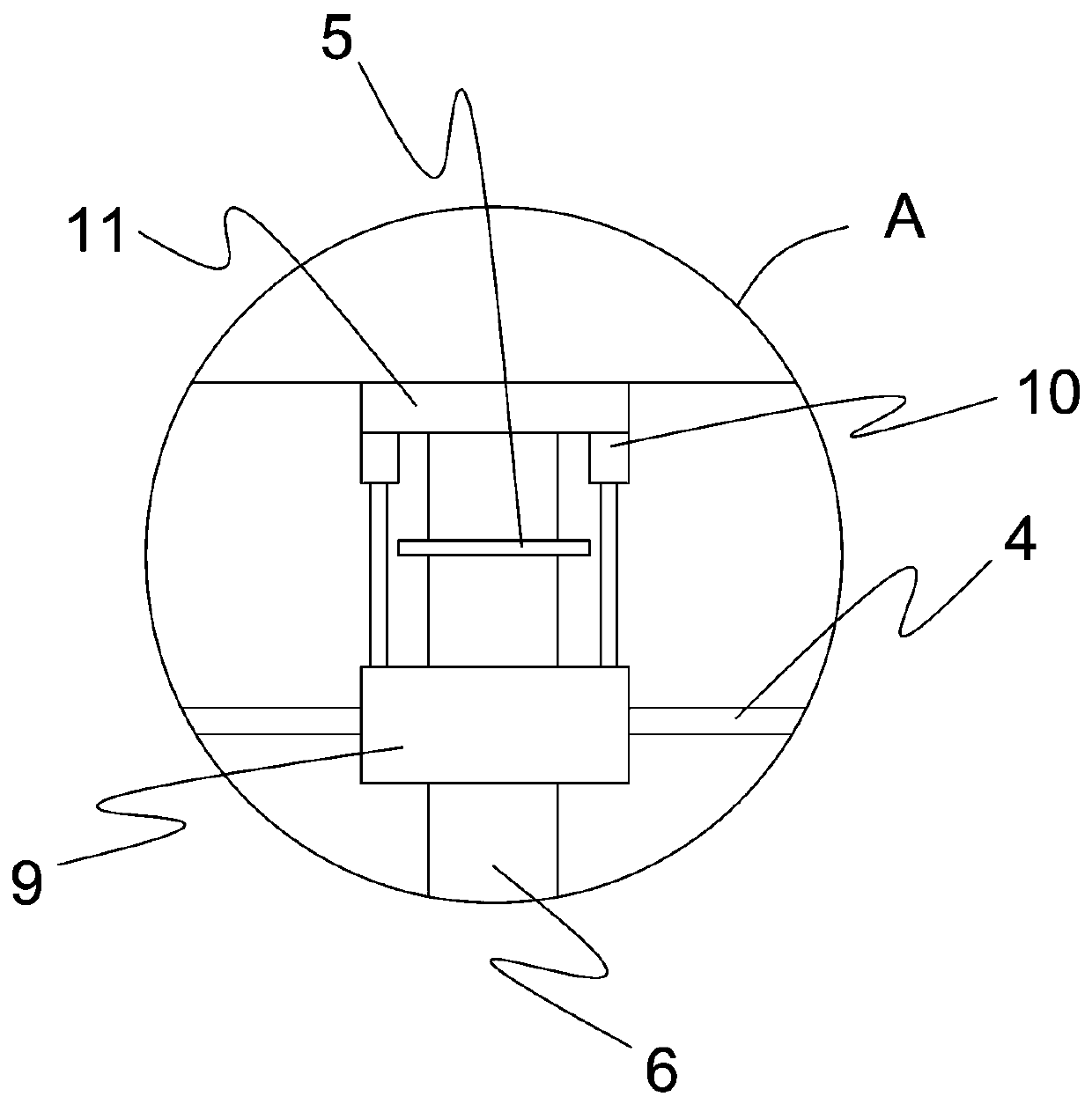

[0019] see figure 1 , figure 2 , image 3 , Figure 4 . An automatic flavoring device for tobacco of the present invention comprises: a housing 1, a rotating rod 6 fixedly connected to the top of the housing 1, a stirring blade 7 arranged at the end of the rotating rod 6 close to the bottom of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com