Machining process of metal automobile door frames

A processing technology and metal technology, applied in the field of automobile metal door frame processing technology, can solve problems such as difficulty in ensuring the dimensional accuracy of the automobile metal door frame, large components of the automobile metal door frame, rusting of the automobile metal door frame, etc., to ensure quality and quality stability, Good rust prevention effect, good oxygen barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

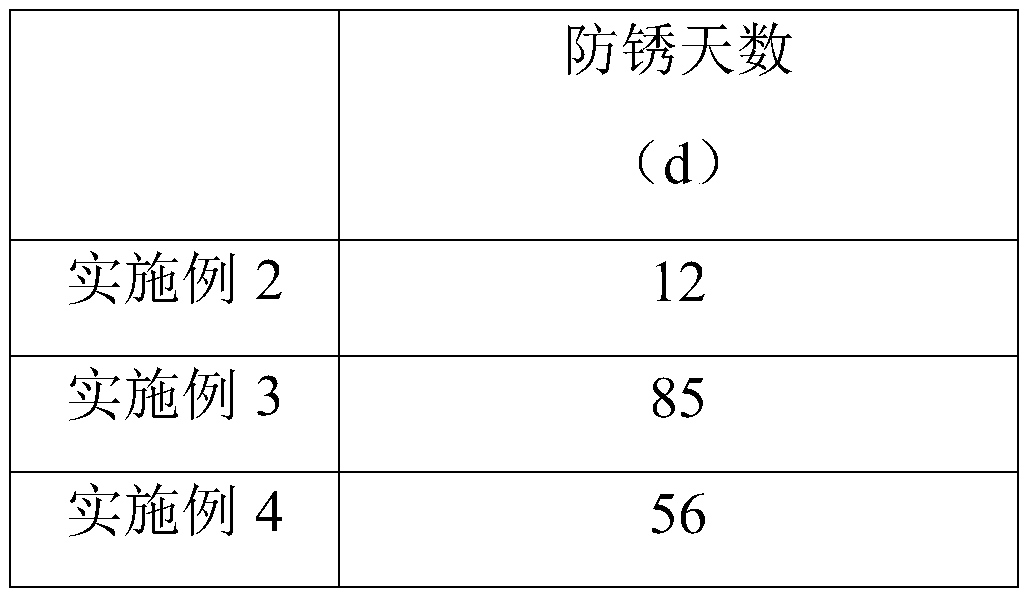

Examples

Embodiment 1

[0043] A kind of automobile metal door frame processing technology, comprises the following steps:

[0044] A. Welding: Weld the cut metal profiles into automobile metal door frames;

[0045] B. Rough grinding: Roughly grind the above-mentioned welded metal door frame of the car, and visually check for defects;

[0046] C. Fine grinding: Use fine grinding equipment to finely grind the metal door frame of the automobile after the above rough grinding, so that the surface roughness reaches 0.5-0.7 mm;

[0047] The fine grinding equipment includes polishing machines, grinders and angle grinders.

[0048] D. Arrange the above-mentioned finely polished automobile metal door frames on the hanger in sequence, and fix the position of each finely polished automobile metal door frame; the hanger is fixed on the hanging conveyor, and the hanging conveyor drives the hanger With assembly line movement, circular conveying;

[0049]E. In the running direction of the hanging conveyor, firs...

Embodiment 2

[0060] A kind of automobile metal door frame processing technology, comprises the following steps:

[0061] A. Welding: Weld the cut metal profiles into automobile metal door frames;

[0062] B. Rough grinding: Roughly grind the above-mentioned welded metal door frame of the car, and visually check for defects;

[0063] C. Fine grinding: Use fine grinding equipment to finely grind the metal door frame of the automobile after the above rough grinding, so that the surface roughness reaches 0.5mm;

[0064] The fine grinding equipment includes polishing machines, grinders and angle grinders.

[0065] D. Arrange the finely polished automobile metal door frames on the hanger in sequence, and fix the position of each finely polished automobile metal door frame; the hanger is fixed on the suspension conveyor, and the hanger is driven by the suspension conveyor With assembly line movement, circular conveying;

[0066] E. In the running direction of the hanging conveyor, first use a ...

Embodiment 3

[0074] A kind of automobile metal door frame processing technology, comprises the following steps:

[0075] A. Welding: Weld the cut metal profiles into automobile metal door frames;

[0076] B. Rough grinding: Roughly grind the above-mentioned welded metal door frame of the car, and visually check for defects;

[0077] C. Fine grinding: use fine grinding equipment to finely grind the metal door frame of the automobile after the above rough grinding, so that the surface roughness reaches 0.7mm;

[0078] The fine grinding equipment includes polishing machines, grinders and angle grinders.

[0079] D. Arrange the finely polished automobile metal door frames on the hanger in sequence, and fix the position of each finely polished automobile metal door frame; the hanger is fixed on the suspension conveyor, and the hanger is driven by the suspension conveyor With assembly line movement, circular conveying;

[0080] E. In the running direction of the hanging conveyor, first use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com