High-performance industrial robot controller

An industrial robot and robot technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as difficulty in meeting the real-time requirements of robots, difficulty in adapting to industrial robot application scenarios, and poor processor computing power, etc. Scalability, high security, and the effect of improving computing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

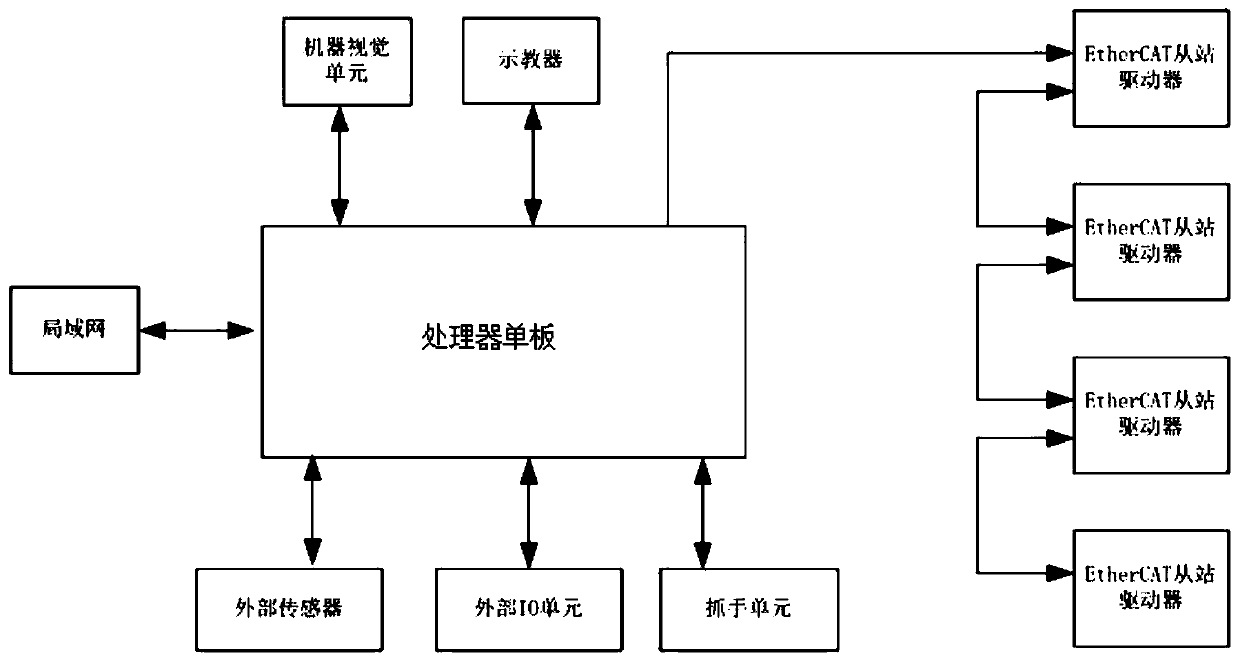

[0041] Such as figure 1 As shown, a high-performance industrial robot controller includes a processor board, a machine vision unit, a teaching pendant, an external IO unit, a gripper unit, an external sensor, and a motor driver;

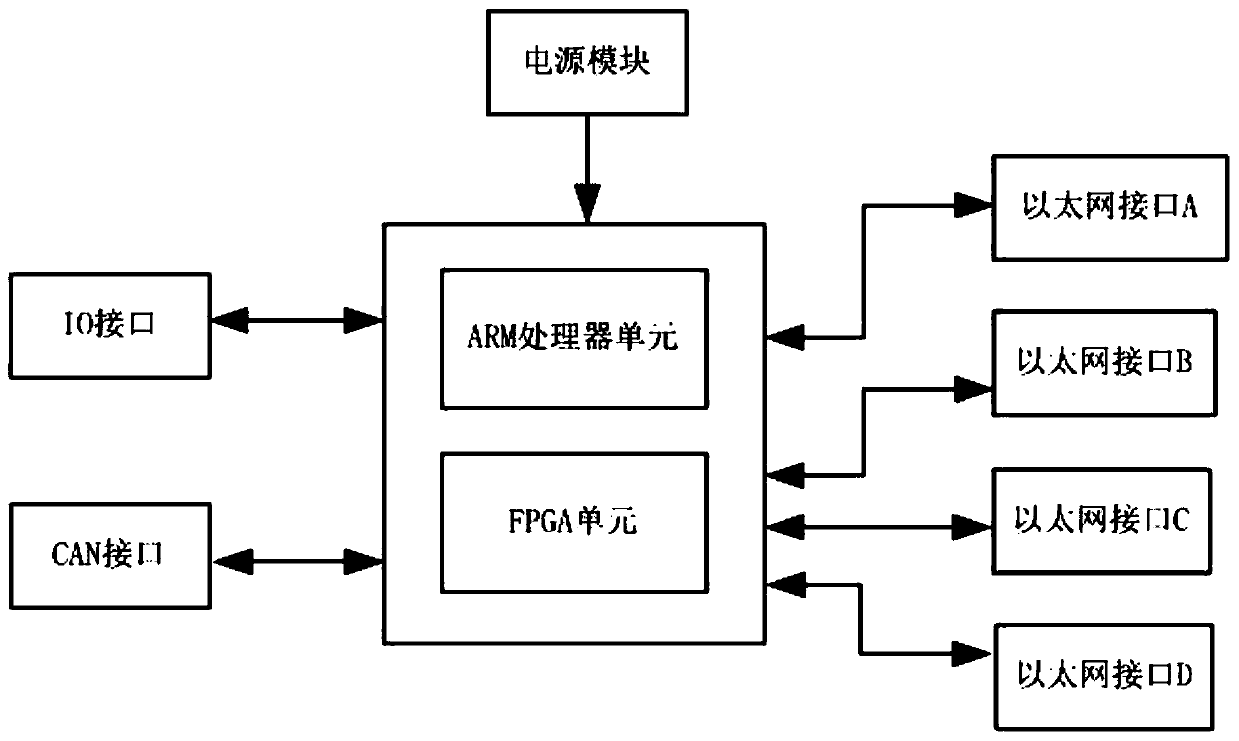

[0042] Among them, such as figure 2 As shown, the processor board includes an ARM processor unit, an FPGA unit, a power module, an Ethernet interface A, an Ethernet interface B, an Ethernet interface C, an Ethernet interface D, an IO interface, and a CAN interface;

[0043] Among them, the FPGA unit and the ARM processing unit are connected through a high-speed link, and two Ethernet interfaces are output from the ARM end, and two Ethernet interfaces are output from the FPGA; the CAN interface and the IO interface are respectively connected to the ARM processor unit, and the power module Provide power for the processor board;

[0044] Among them, the Ethernet interface B of the processor board is connected to the teaching pendant, the Ethernet int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com