Clay sculpture printer convenient to dry

A technology of printers and clay sculptures, which is applied to ceramic forming machines, manufacturing tools, additive processing, etc., can solve the problems of poor molding effect and poor drying effect, and avoid low weather temperature, facilitate post-drying, Ensure the effect of the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

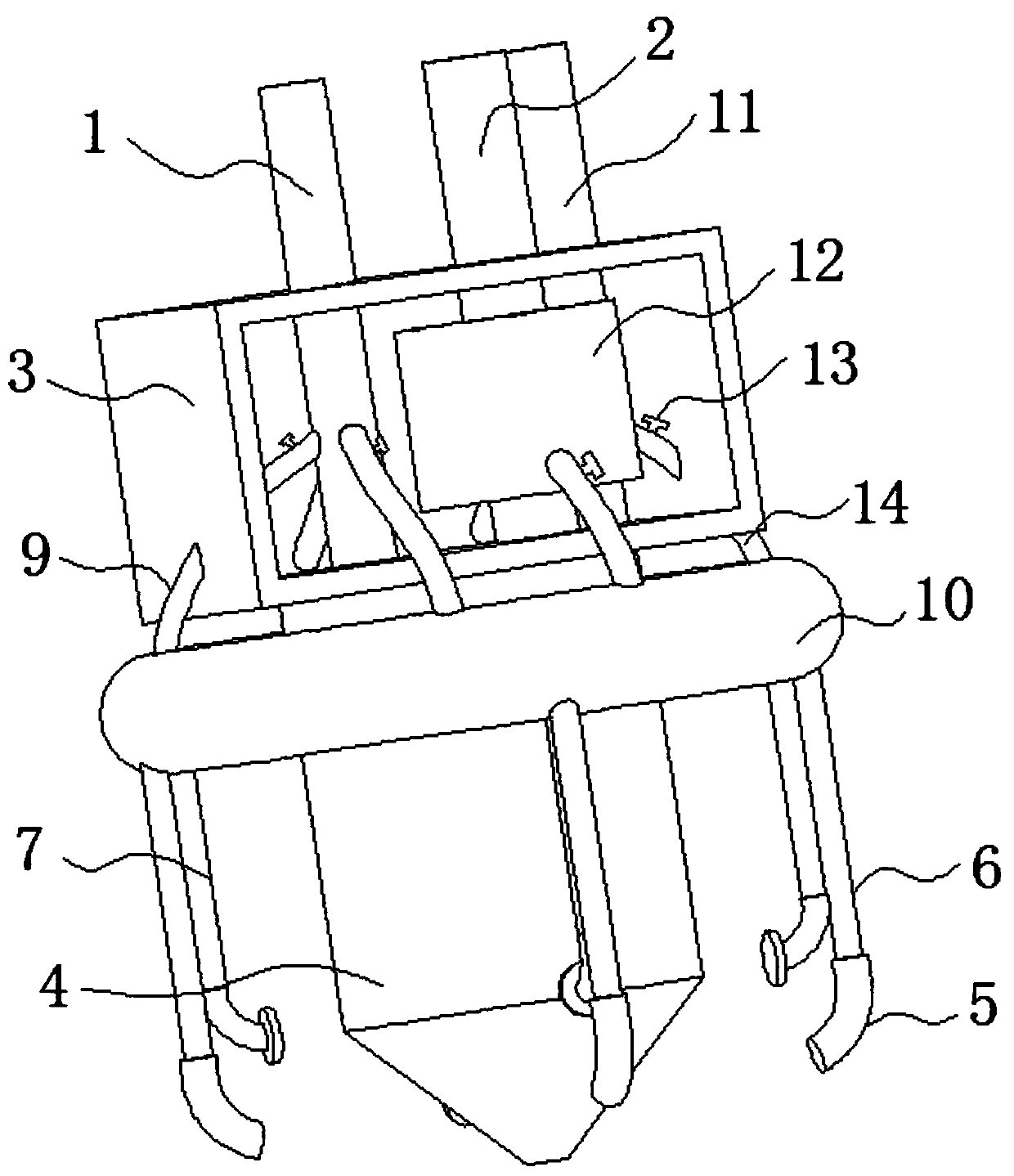

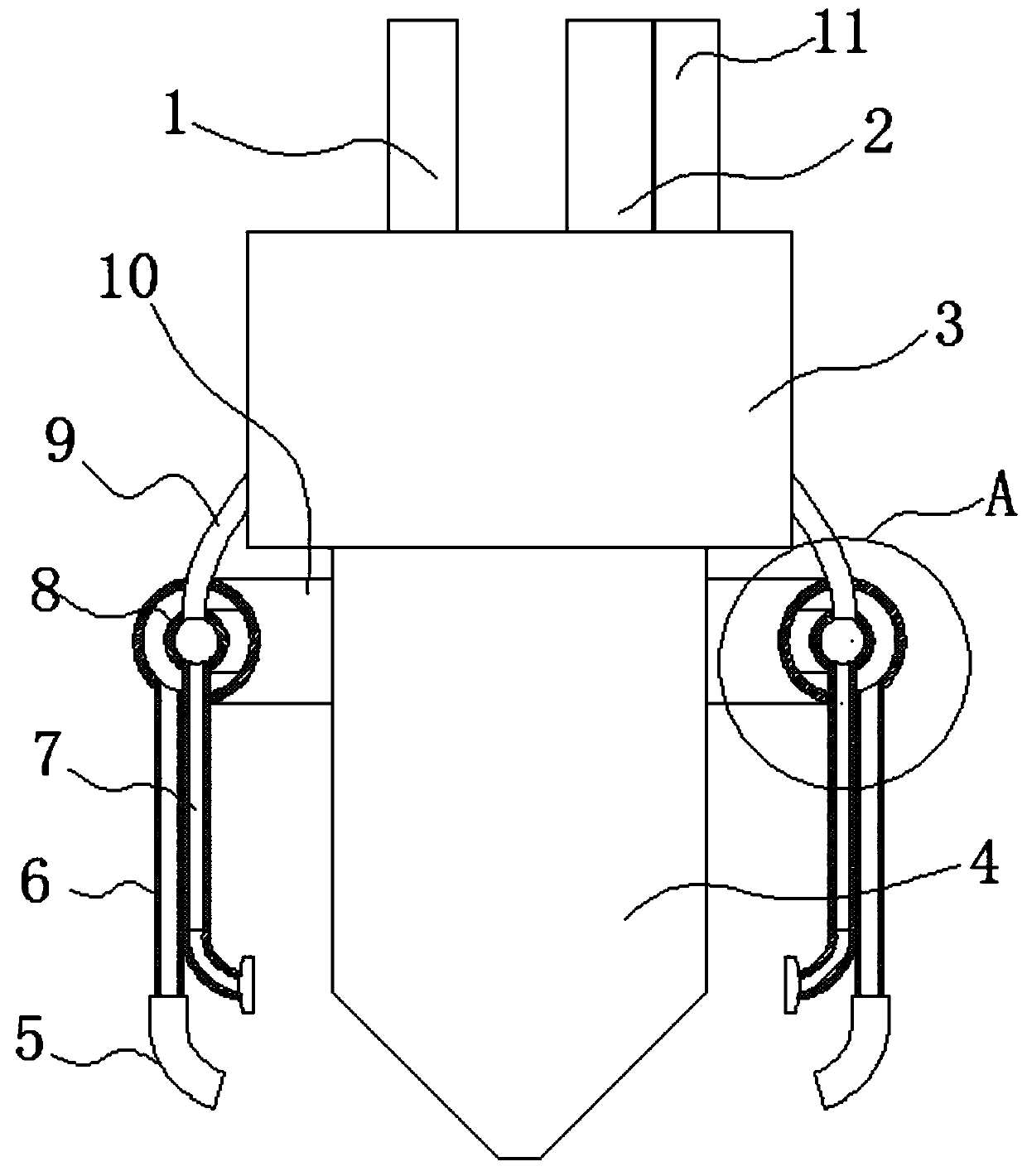

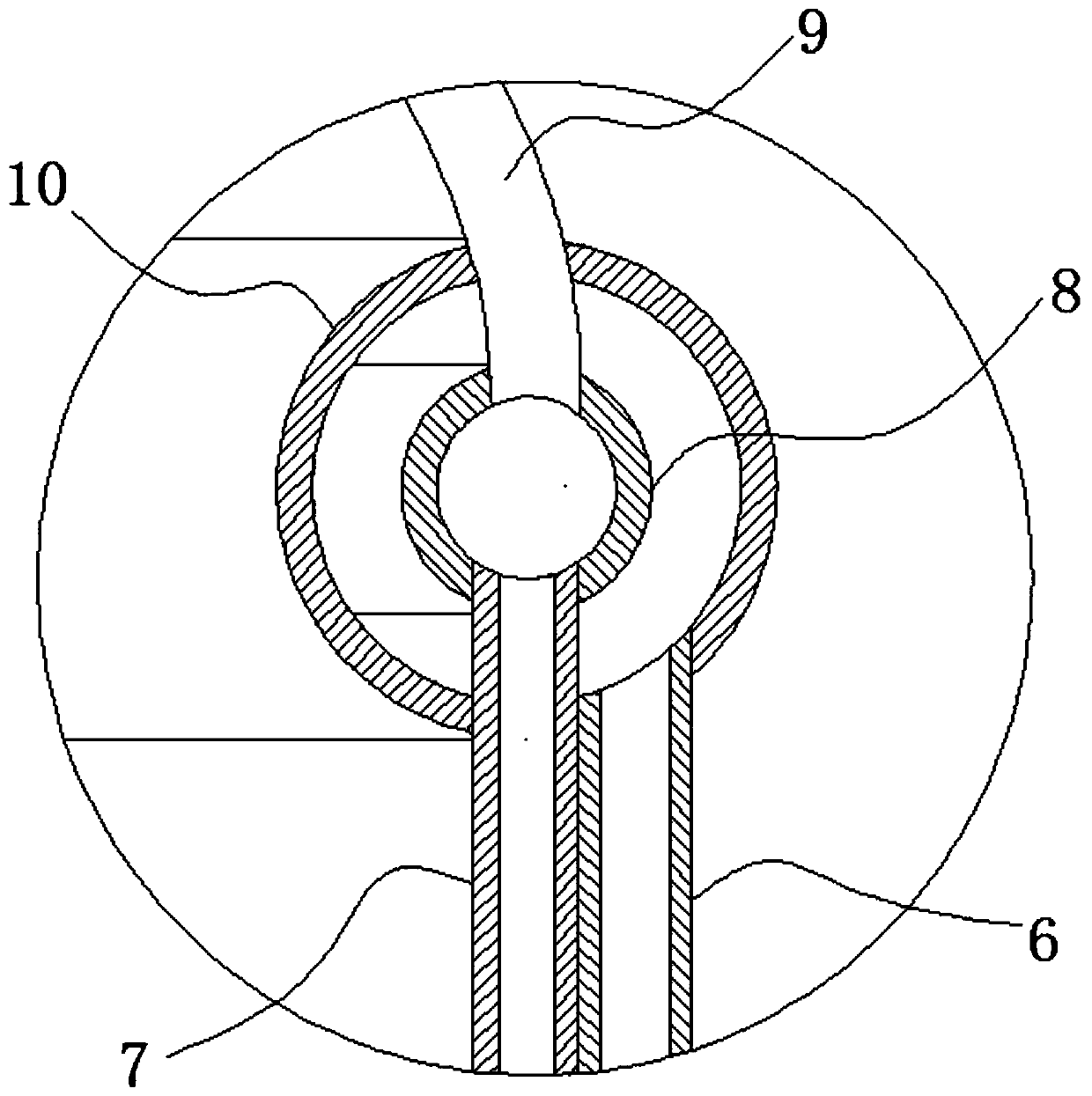

[0026] refer to Figure 1-4 , a kind of clay sculpture printer that is convenient to dry, comprises frame, controller 15 and mud outlet head 4, controller 15 and mud outlet head 4 are all connected on the frame, mud outlet head 4 is connected with inlet through connection box 3 The water pipe 1 and the feed pipe 2, the lower end of the connection box 3 is sleeved with a hot gas ring pipe 10, the bottom side of the hot gas ring pipe 10 is connected with a drying pipe 6, the lower end of the drying pipe 6 is connected with an arc-shaped hot gas head 5, and the hot gas ring pipe 10 The hot air delivery pipe 14 is connected to the top, and the air intake pipe 11 is connected to the hot air delivery pipe 14. When printing, the mud head is driven by the frame to move to realize the mud forming. When forming, the water inlet pipe 1 and the feed pipe 2 are used The mud discharge head 4 carries out the mud discharge molding, and at the same time, after the mud discharge is formed, the ...

Embodiment 2

[0028] refer to Figure 1-4 , a clay sculpture printer that is easy to dry, basically the same as Embodiment 1, and further, the hot gas delivery pipe 14 and the drying pipe 6 are connected with a solenoid valve 13, and the solenoid valve 13 is electrically connected with the controller 15, through The electromagnetic valve 13 is convenient to control the opening and closing of the hot gas conveying pipe 14 and the drying pipe 6 .

Embodiment 3

[0030] refer to Figure 1-4 , a kind of clay sculpture printer that is easy to dry, is basically the same as embodiment 1, further, is connected with the preheating sleeve 12 between the hot air conveying pipe 14 and the air inlet pipe 11, and the preheating sleeve 12 is sleeved on the feeding pipe 2, the feed pipe 2 can be preheated through the preheating sleeve 12 to ensure the temperature of the raw materials for the mud, which can further effectively prevent the clay molding temperature from being too low and ensure the quality of subsequent drying.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap