Marine Cargo Lifting Device

A lifting device and cargo technology, which is applied in the direction of lifting devices, cargo, cargo handling equipment, etc., can solve the problems of affecting the efficiency of cargo transfer in boxes, shaking of the ship hull, and increasing labor costs, so as to achieve easy and convenient lifting and transfer, and prevent breakage , Improve the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

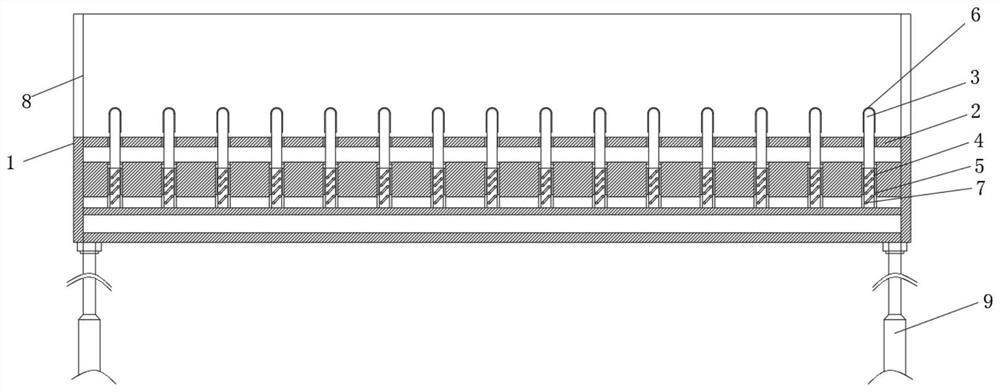

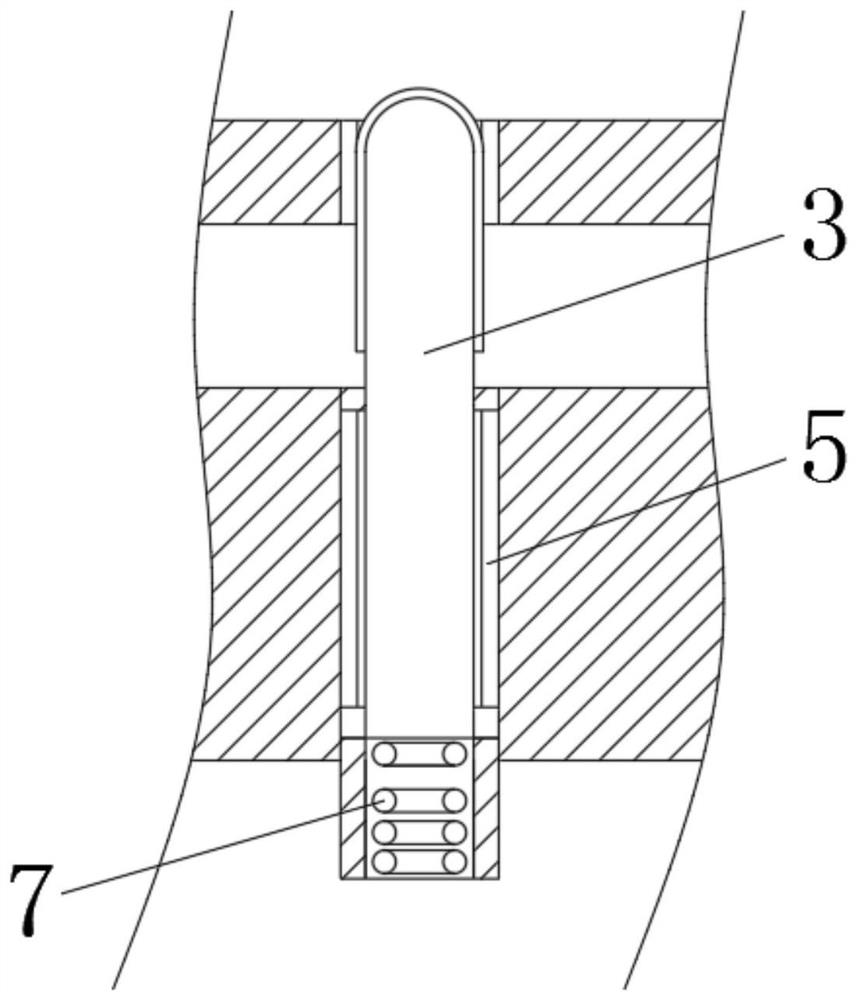

[0021] Such as Figure 1-2 As shown, the marine cargo lifting device includes a lifting rod 9, a lifting plate 1 is fixedly installed on the outer surface of the upper end of the lifting rod 9, and a guardrail 8 is fixedly installed on the outer surface of the upper end of the lifting plate 1 near the surroundings. The outer surface of the upper end of the lifting plate 1 is provided with a moving hole 4, and the inner wall surface of the moving hole 4 is provided with a limit moving groove 5, and a limiting column 3 is arranged in the moving hole 4, and the outer surface of the limiting column 3 A limiting moving block is provided, the limiting moving block moves up and down in the limiting moving groove 5, the limiting column 3 is limited to moving up and down in the moving hole 4, and the outer surface of the lower end of the limiting column 3 is fixedly connected with a compression spring 7 The outer surface of the upper end of the lifting plate 1 is also laid with an elas...

Embodiment 2

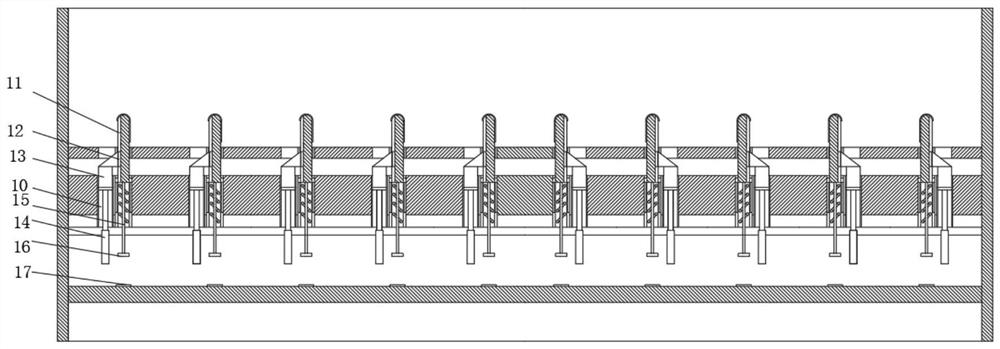

[0024] On the basis of above-mentioned embodiment 1, in order to further improve the stability of this device, make further improvement, as Figure 3-5 As shown, the outer surface of the upper end of the lifting plate 1 is provided with a lifting and moving groove 10, and the outer surface of the limiting column 3 and the lifting and moving groove 10 are provided with a chute 11, and a limiting block is arranged in the chute 11 12. The lower end of the limiting block 12 is fixedly connected with a resisting block 13, and the outer surface of the lower end of the resisting block 13 is fixedly connected with a telescopic rod 14, and the resisting block 13 moves in the lifting and moving groove 10 through the telescopic rod 14, and resists Block 13 is structured as image 3 As shown; one group of said restricting column 3 is provided with two groups of adjacent chute 11, and each group of said chute 11 is provided with a restricting block 12; also includes a control machine, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com