Platform type overturning machine

A flipping machine, platform type technology, applied in the direction of lifting device, hoisting device, etc., can solve the problems of failure to form a system, scattered flipping mechanism, low precision, etc., and achieve the effect of compact overall structure, good clamping effect, and guaranteed accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

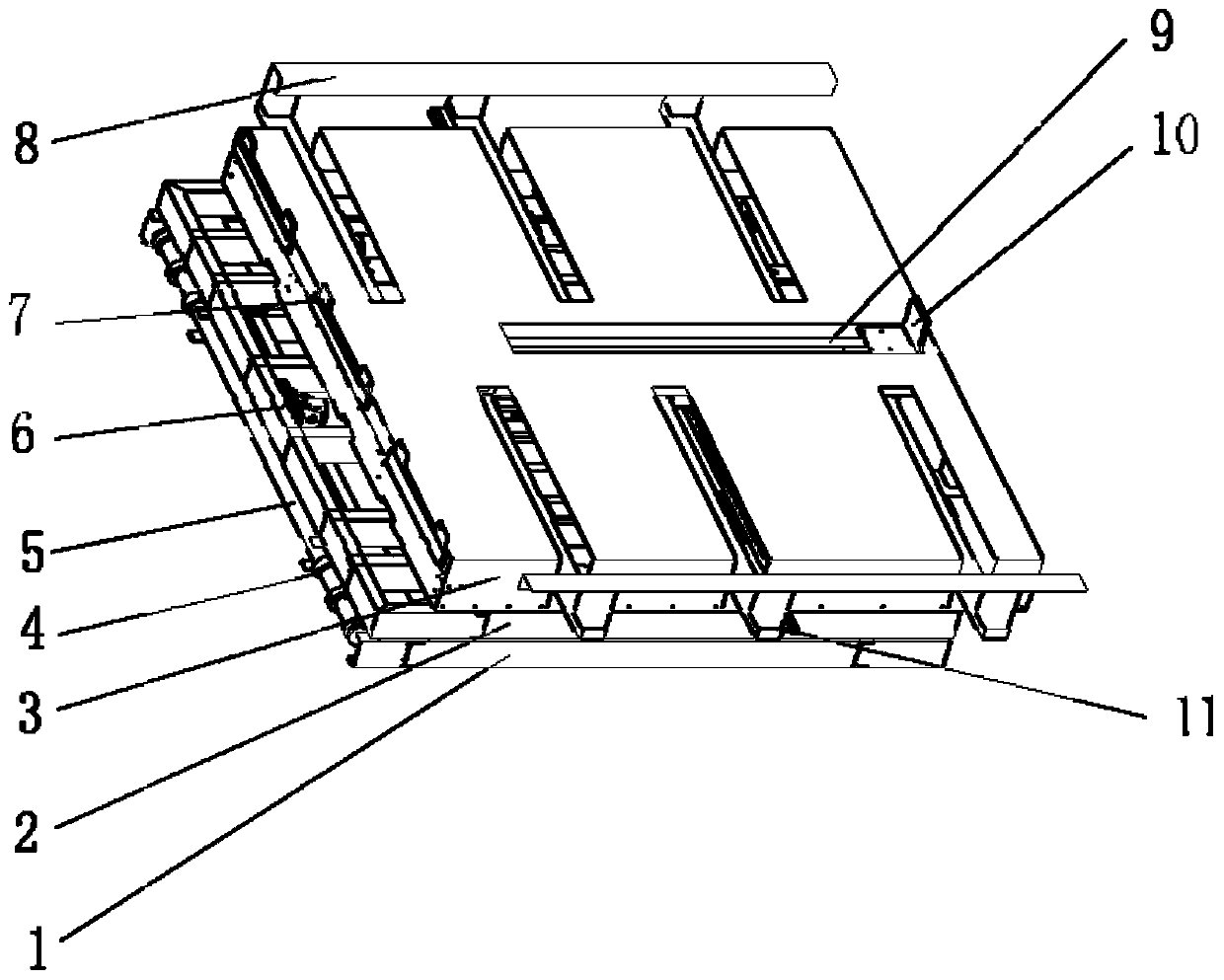

[0035] A platform type turning machine, comprising a support base with multi-layer sub-supports and a clamping mechanism, the clamping mechanism is connected to the top of the support base;

[0036] Among them, the multi-layer sub-supports are connected sequentially, the sub-supports on the middle layer are connected to the sub-supports on the top layer, and the sub-supports on the middle layer and the sub-supports on the top layer can be displaced relatively, and the sub-supports on the bottom layer are hinged to the sub-supports on the middle layer. sub-supports, and the sub-supports located at the bottom layer can rotate relative to the sub-supports located at the middle layer.

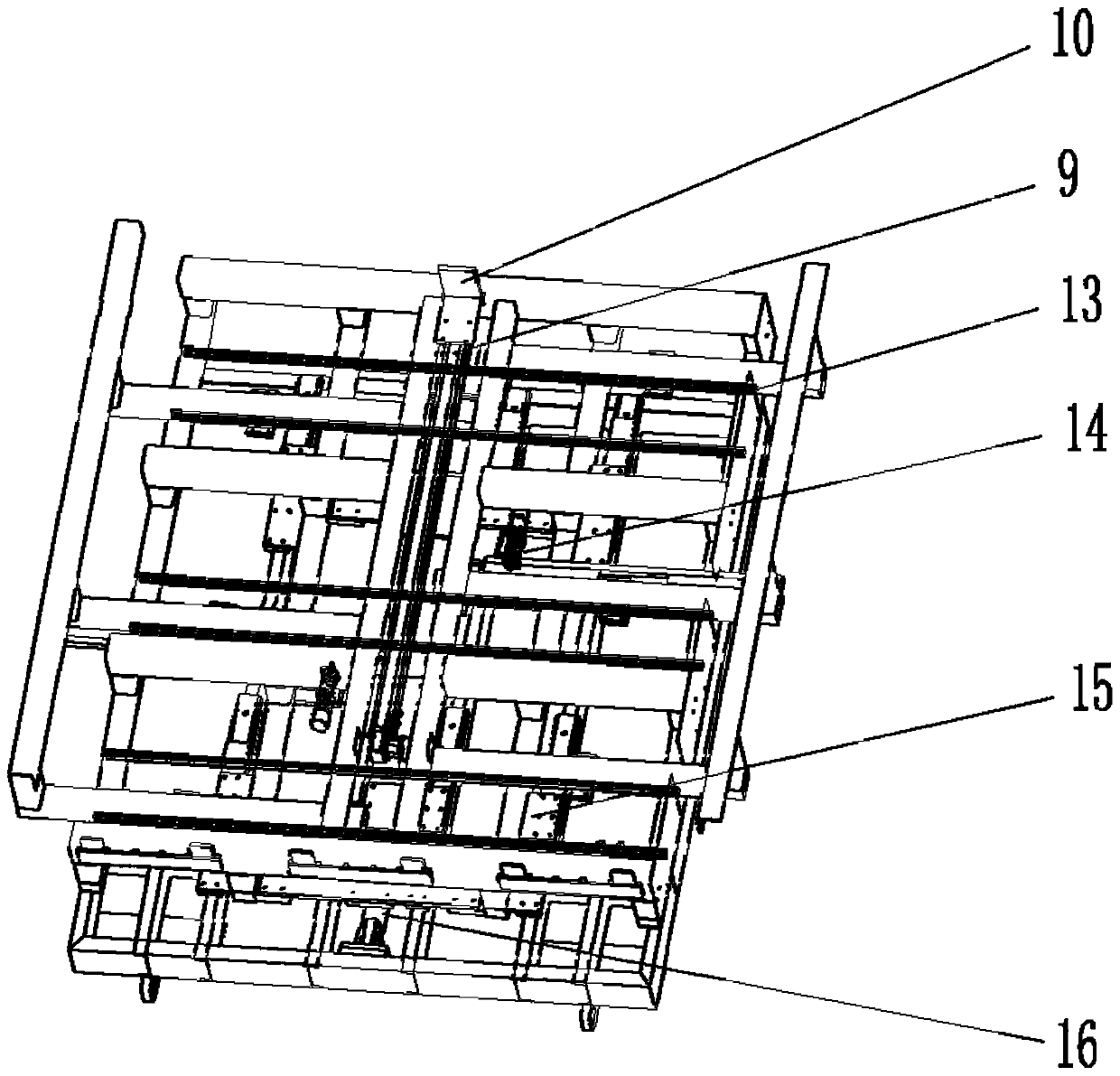

[0037] The sub-support includes three layers, respectively the first sub-support 1, the second sub-support 2 and the third sub-support 3 connected in sequence, the second sub-support 2 and the third sub-support 3 are slidably connected, and the first sub-support 1 Hinged with the second sub-bracket...

Embodiment 2

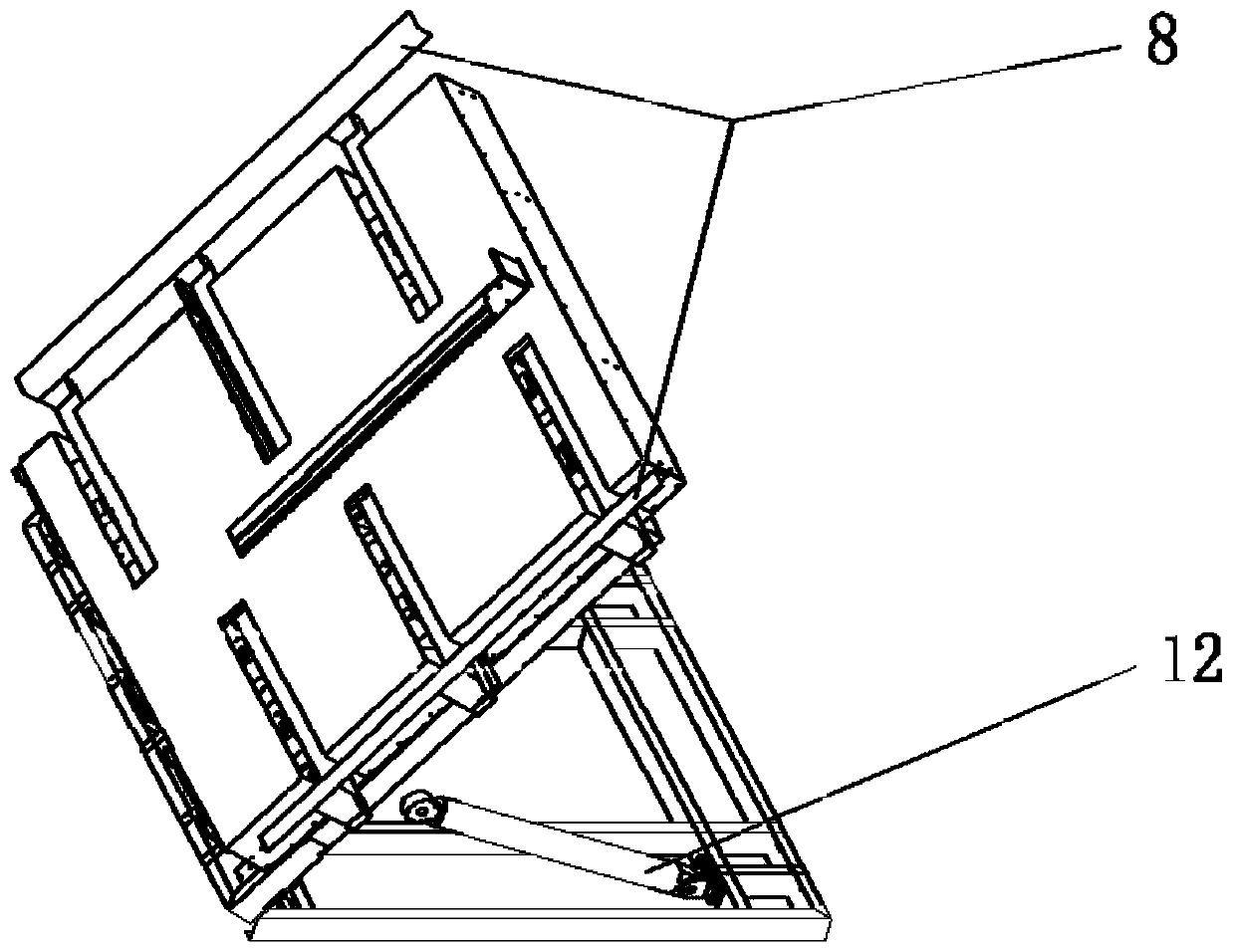

[0054] Embodiment 2 discloses a platform-type overturning method, which uses the platform-type overturning machine as described in Embodiment 1, and can control the inclination angle of the sub-support located on the top floor by controlling the first telescopic rod 12, and by controlling the second telescopic rod 16 can control the spatial position of the sub-support located on the top floor. By controlling the clamping mechanism, the clamping mechanism can clamp the product to be processed; The tightening mechanism can clamp the product at a certain position, and control the first telescopic rod 12 to turn the product over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com