Multifunctional bottle opener

A bottle opener and multi-functional technology, which is applied in the disassembly of finger-shaped grab hooks and screw caps, etc., can solve the problem of poor versatility and cannot open various caps of different sizes, and achieves simple and compact structure and strong versatility , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

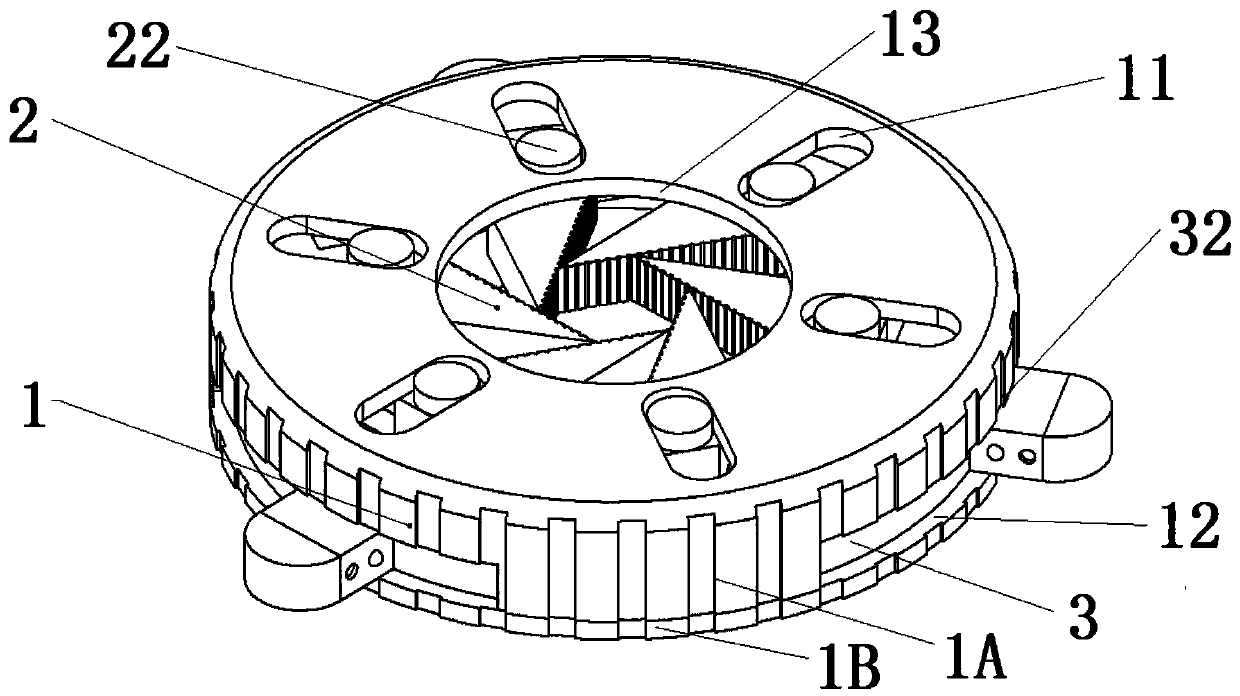

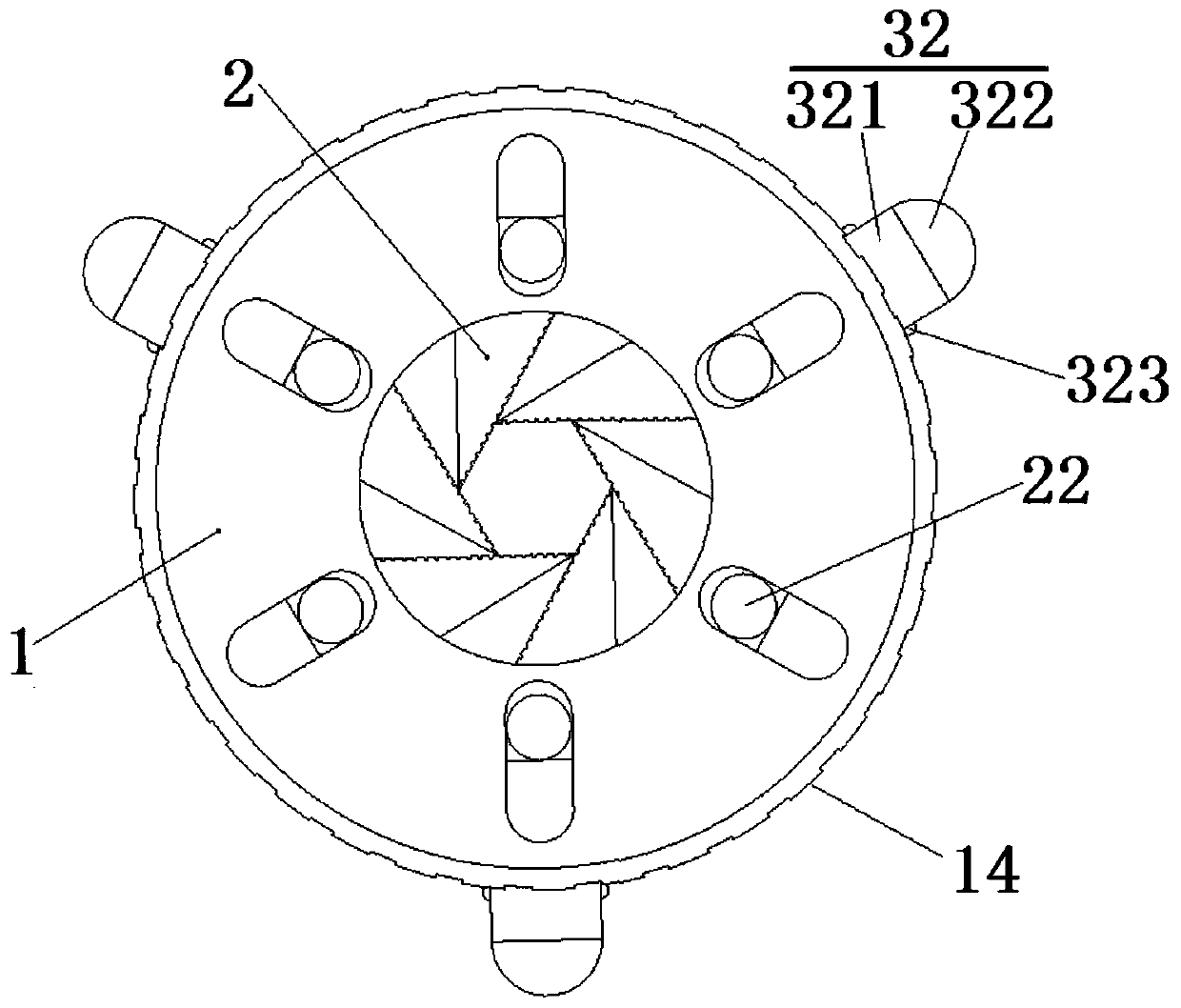

[0022] Such as Figure 2 to Figure 6 As shown, the multifunctional bottle opener includes a screw cap 1, a plurality of clamping blocks 2 and a base 3,

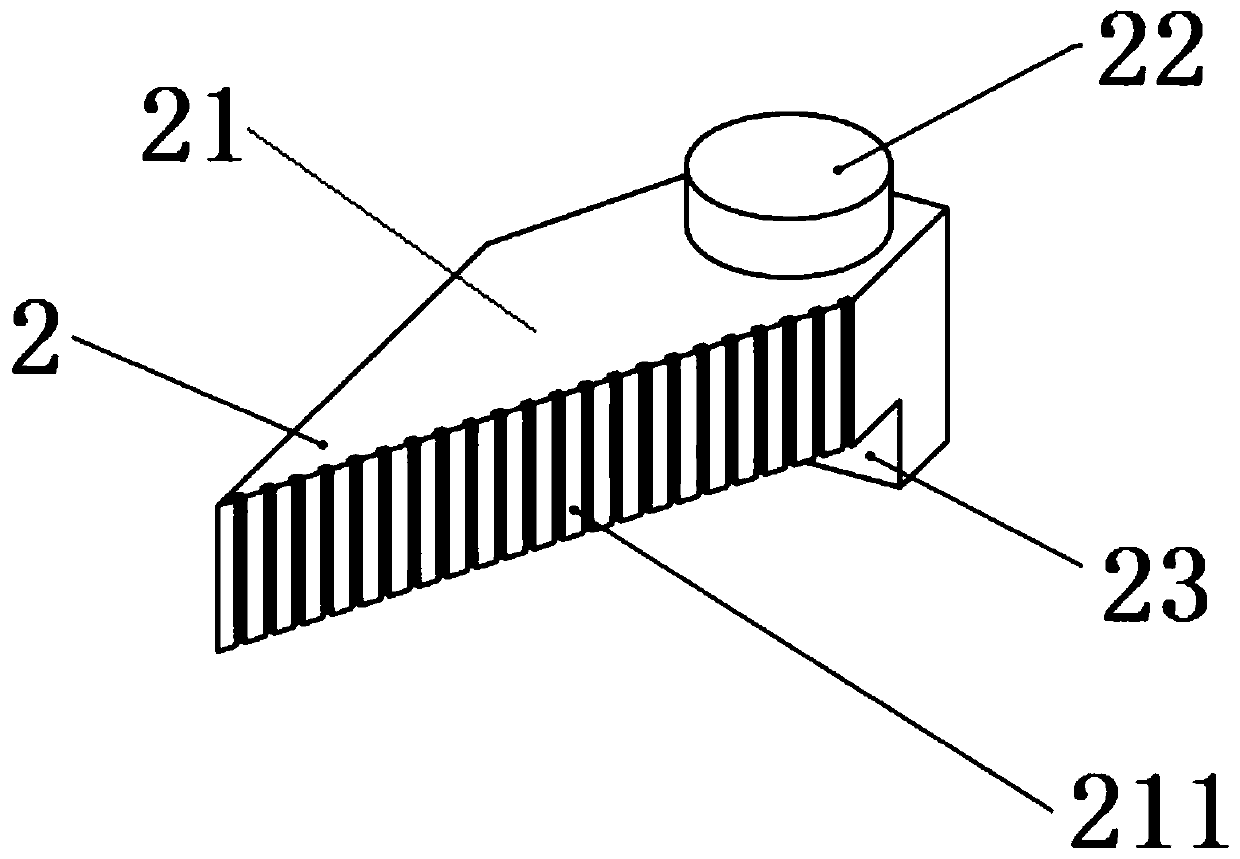

[0023] The clamping block 2 includes a clamping block body 21, a circular platform 22 and a protruding block 23 respectively fixed on the upper and lower surfaces of the clamping block body 21;

[0024] The base 3 is provided with a plurality of grooves 31 for accommodating the protruding blocks 23 of the plurality of clamping blocks 2. The plurality of grooves 31 communicate with each other and are distributed in a circular array along the central axis of the base 3; A handle 32, the middle part of the base 3 offers a through hole 33 for the bottle cap to pass through;

[0025] The inside of the screw cap 1 has a cavity for accommodating multiple clamping blocks 2 and the base 3, and a plurality of first through holes 11 for the round table 22 to protrude are provided along the circumferential direction of the upper end sur...

Embodiment 2

[0034] Such as Figure 1 to Figure 5 , Figure 7 As shown, the multifunctional bottle opener includes a screw cap 1, a plurality of clamping blocks 2 and a base 3,

[0035] The clamping block 2 includes a clamping block body 21, a circular platform 22 and a protruding block 23 respectively fixed on the upper and lower surfaces of the clamping block body 21;

[0036] The base 3 is provided with a plurality of grooves 31 for accommodating the protruding blocks 23 of the plurality of clamping blocks 2. The plurality of grooves 31 communicate with each other and are distributed in a circular array along the central axis of the base 3; A handle 32, the middle part of the base 3 offers a through hole 33 for the bottle cap to pass through;

[0037] The inside of the screw cap 1 has a cavity for accommodating multiple clamping blocks 2 and the base 3, and a plurality of first through holes 11 for the round table 22 to protrude are provided along the circumferential direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com