1050 m<3> class blast furnace cold stoking material preparing technology

A stuffy furnace and blast furnace technology, which is applied in the field of 1050m³ blast furnace stuffy charge preparation technology, can solve the problems of blast furnace start-up, unreasonable slag system composition, stuffy furnace charge burnout, etc., and achieve good slag fluidity and slag composition Science, the effect of abundant heat in the hearth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A preparation method for a 1050m³ blast furnace stuffing charge. Specifically, the technical solution includes the following:

[0034] In the step B, the ratio of sintered ore accounts for 85%, the ratio of pelletized ore accounts for 10%, and the ratio of raw ore accounts for 5%.

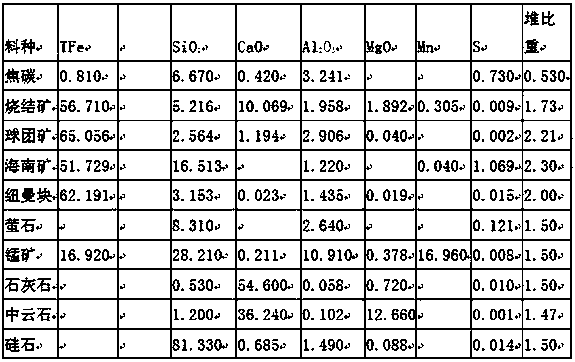

[0035] In the step B, the ingredients of various raw materials in the furnace charge are as follows.

[0036]

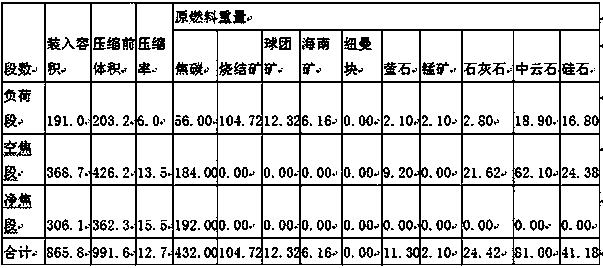

[0037] In the step B, the charging amount of each section is as follows.

[0038]

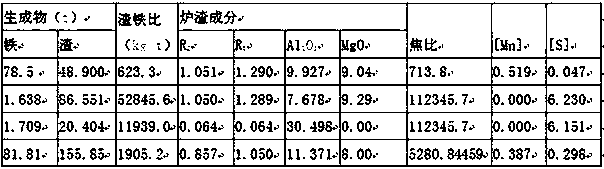

[0039] In the step B, the stuffy charge products are shown in the table below.

[0040]

[0041] Through the preparation of a reasonable and scientific blast furnace material structure, the blast furnace can be shut down for 22 days with a full material line of 1.3 meters. During the start-up of the blast furnace, the heat in the hearth is abundant and the slag has good fluidity. After 30 hours of full-air smelting, the utilization factor of the blast furnace reaches an excellent index o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com