Turbofan engine control system and method based on rapid prototype

A turbofan engine and control system technology, applied in machine/engine, gas turbine engine testing, engine ignition, etc., can solve the problems of unsatisfactory rapid engine development, high cost of electronic controller, poor versatility, etc., and shorten the development cycle , low cost, and the effect of reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, content, and advantages of the present invention clearer, the specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

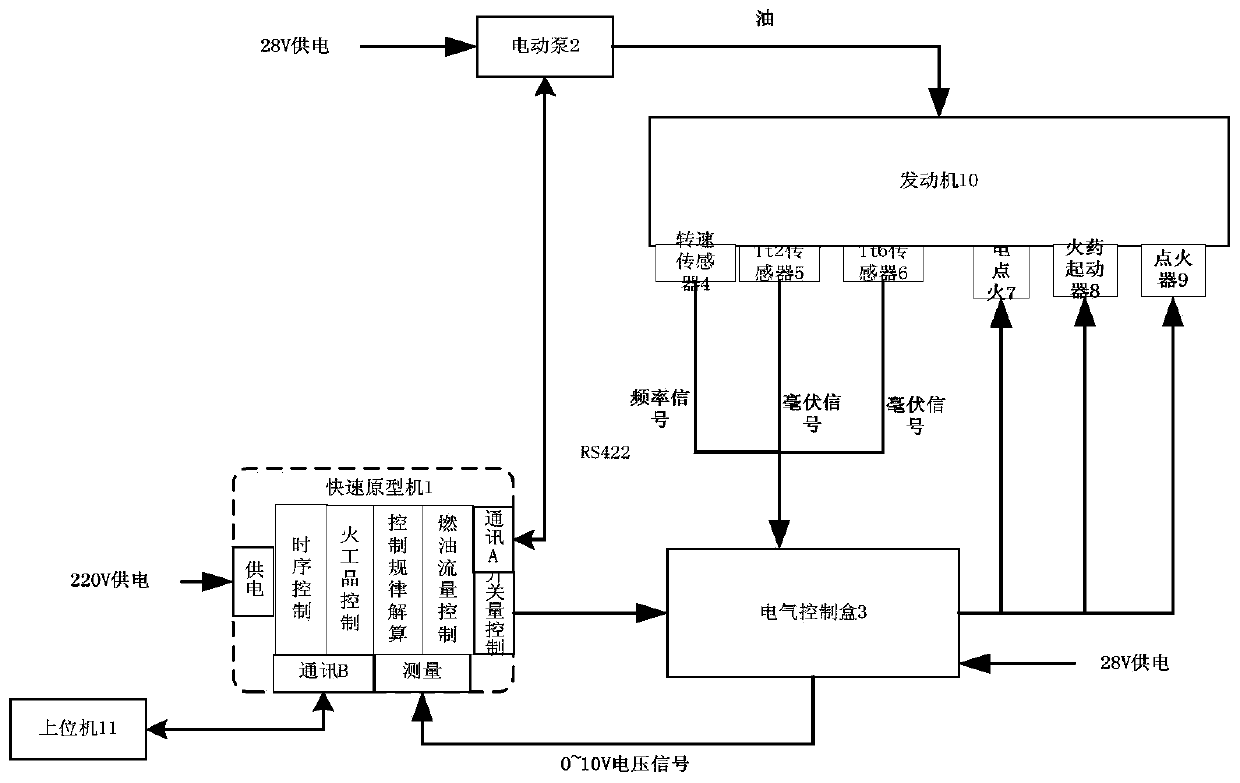

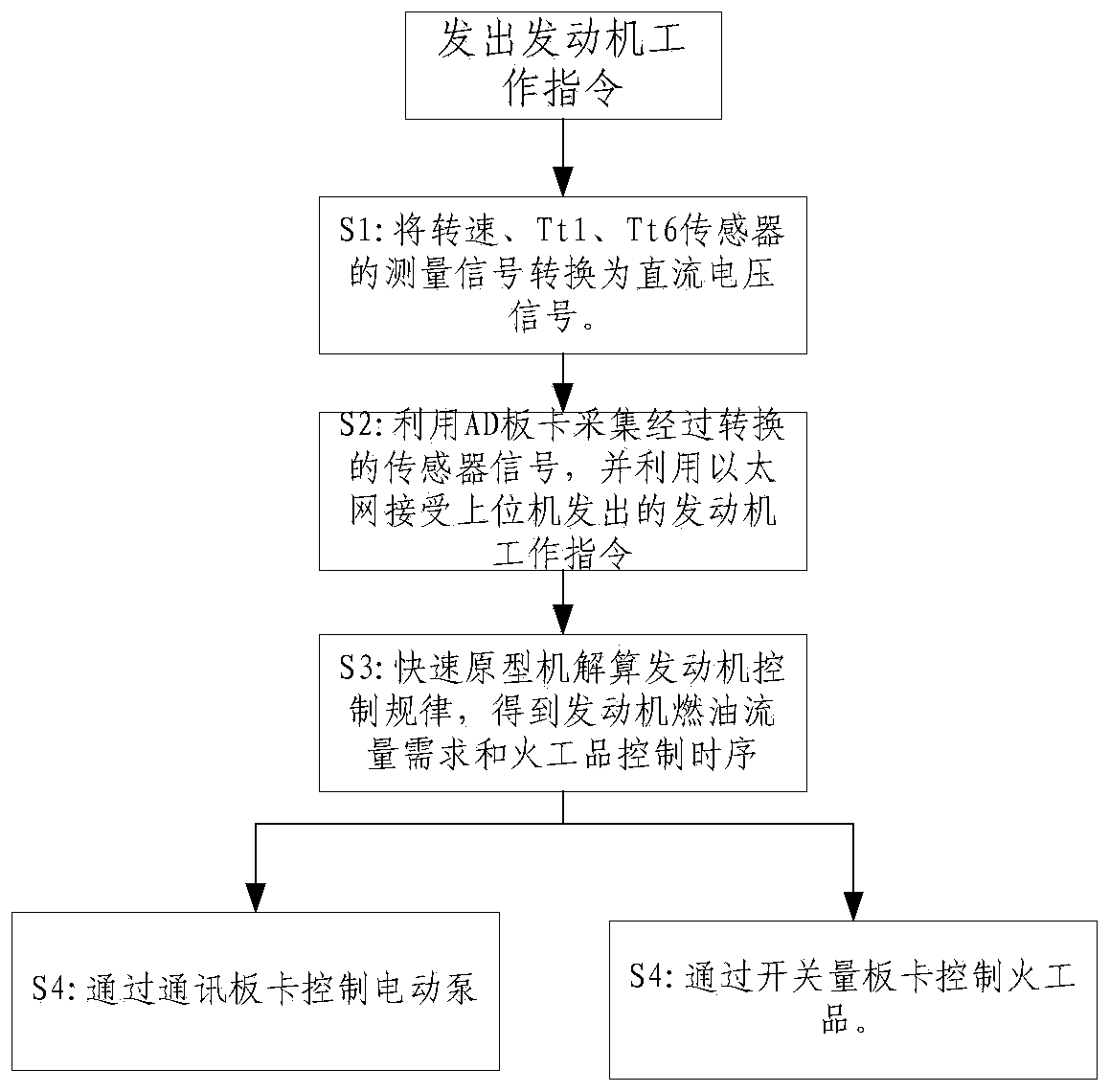

[0039] figure 1 It is a schematic diagram of a turbofan engine control system based on a rapid prototyping machine. The system composition includes rapid prototyping machine 1, electric pump 2, electrical control box 3, speed sensor 4, incoming flow temperature Tt2 sensor 5, exhaust temperature Tt6 Sensor 6, electric ignition 7, gunpowder starter 8, igniter 9, engine 10, upper computer 11.

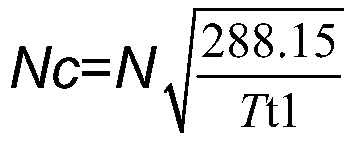

[0040] Among them, the speed sensor 4, the Tt2 sensor 5, and the Tt6 sensor 6 are respectively used to measure the physical speed N of the engine 10, the total incoming flow temperature Tt1 and the exhaust temperature Tt6;

[0041] The electrical control box 3 includes an F / V conversion module and a signal amplification and conditioning module. The F / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com