A nut-driven hydrostatic screw pair

A driving type and screw pair technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of large rotating inertia force, heat generation, energy consumption and other problems of the screw, so as to simplify the oil supply channel and avoid Direct connection, the effect of improving superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

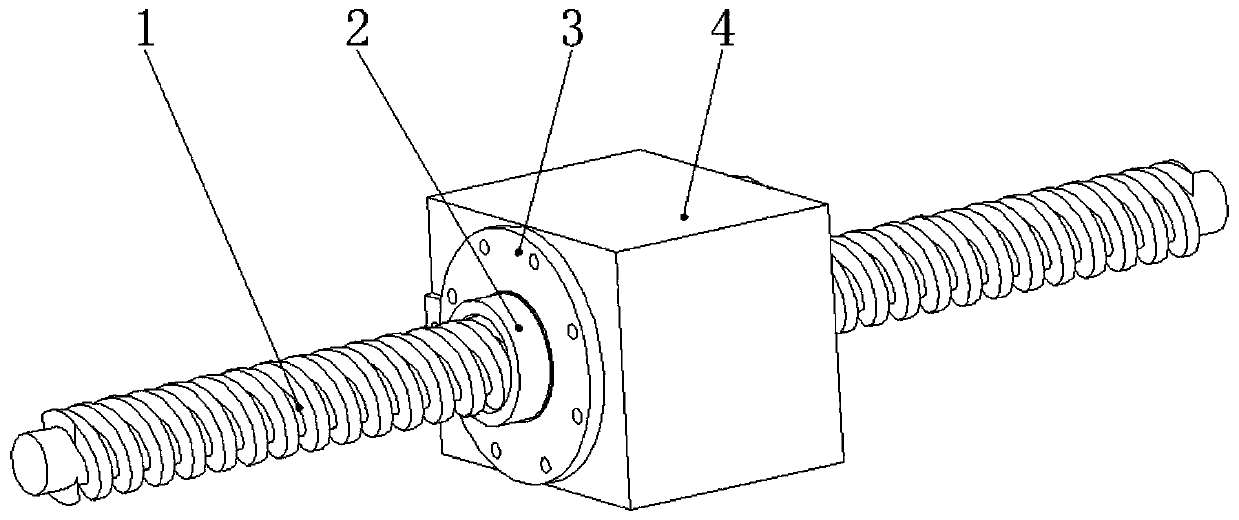

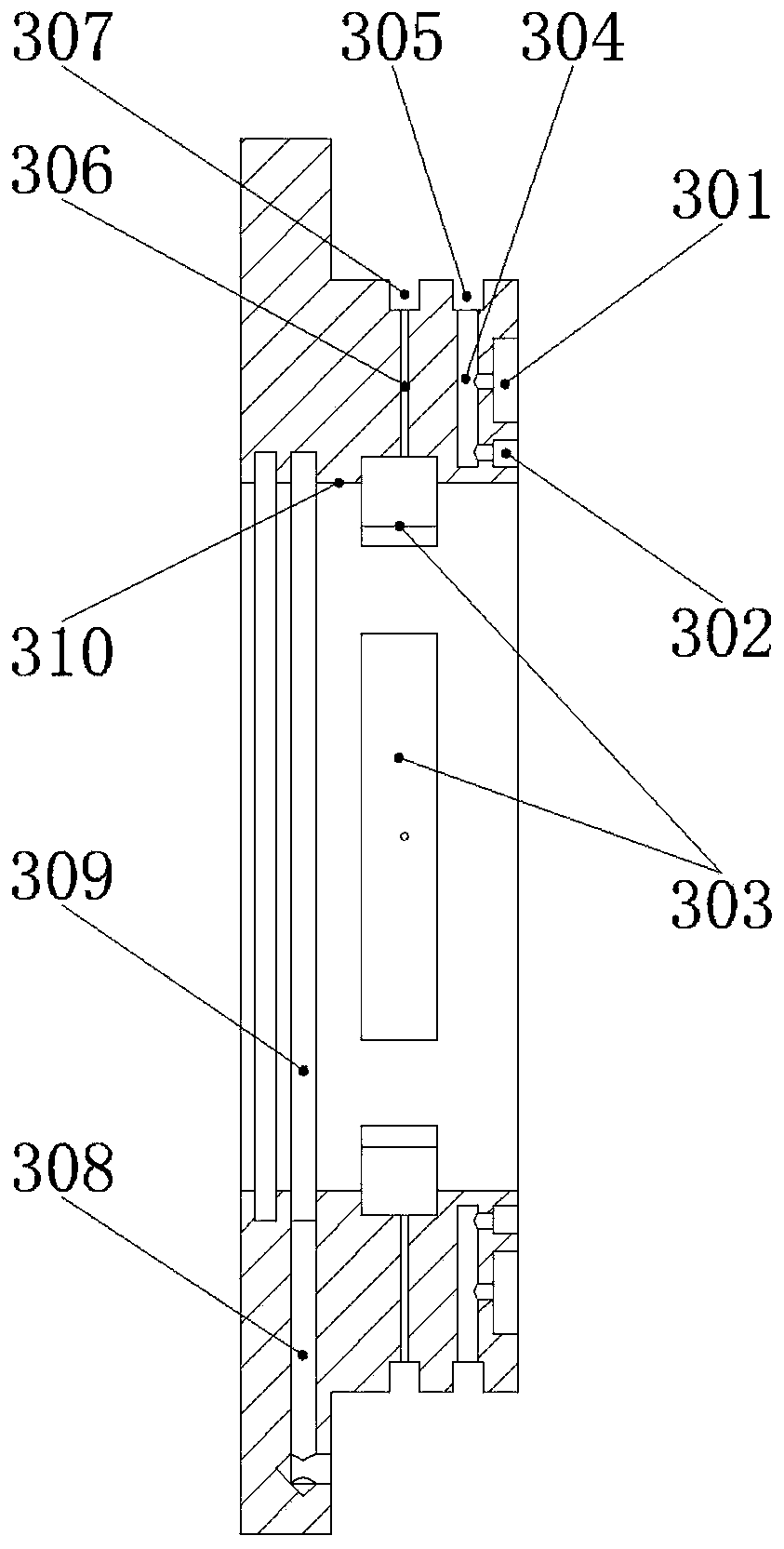

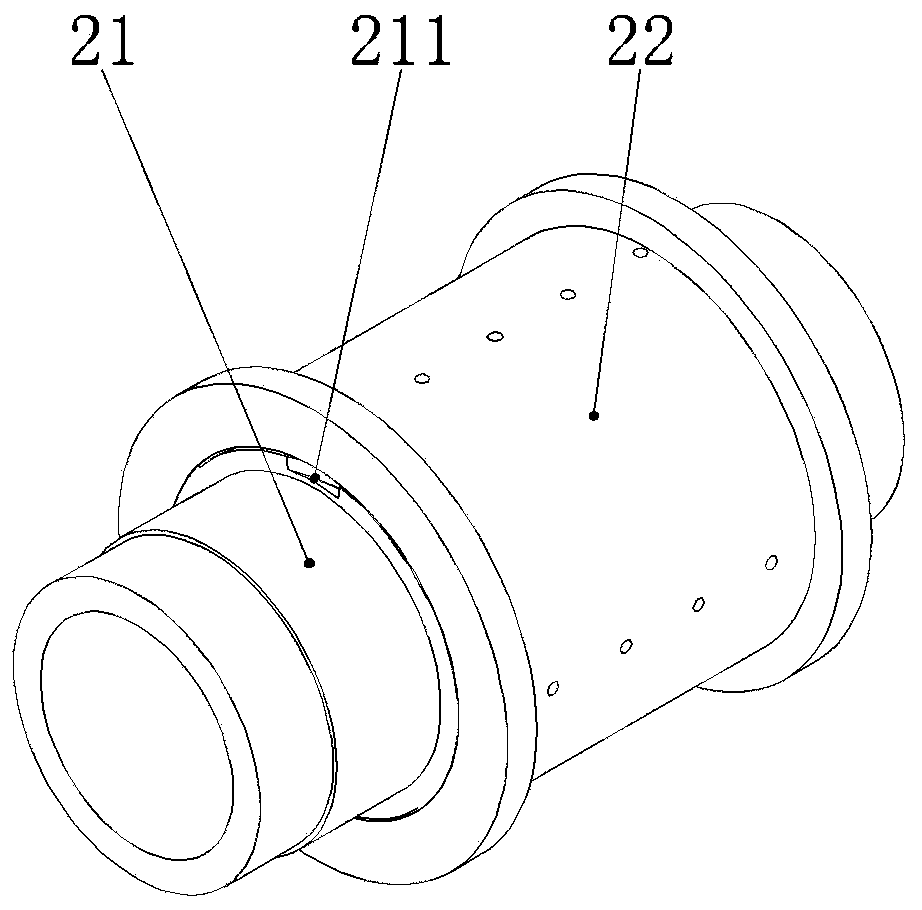

[0034] A nut-driven hydrostatic screw pair, such as figure 1 As shown, it includes a lead screw 1 and a static pressure nut 2 that cooperate with each other. There are two static pressure composite bearings 3, which are respectively installed at the front and rear ends of the static pressure nut 2. The two static pressure composite bearings 3 realize the static pressure of the static pressure nut 2. Static pressure axial support, static pressure radial support, and play the role of oil supply for the static pressure nut 2. The main components of the static pressure nut 2 and the static pressure composite bearing 3 will be separately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com