Drive units with superposition gearing

A technology of transmission and drive equipment, applied in transmission, transmission control, gear transmission, etc., can solve problems such as damaged parts and inability to withstand high rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

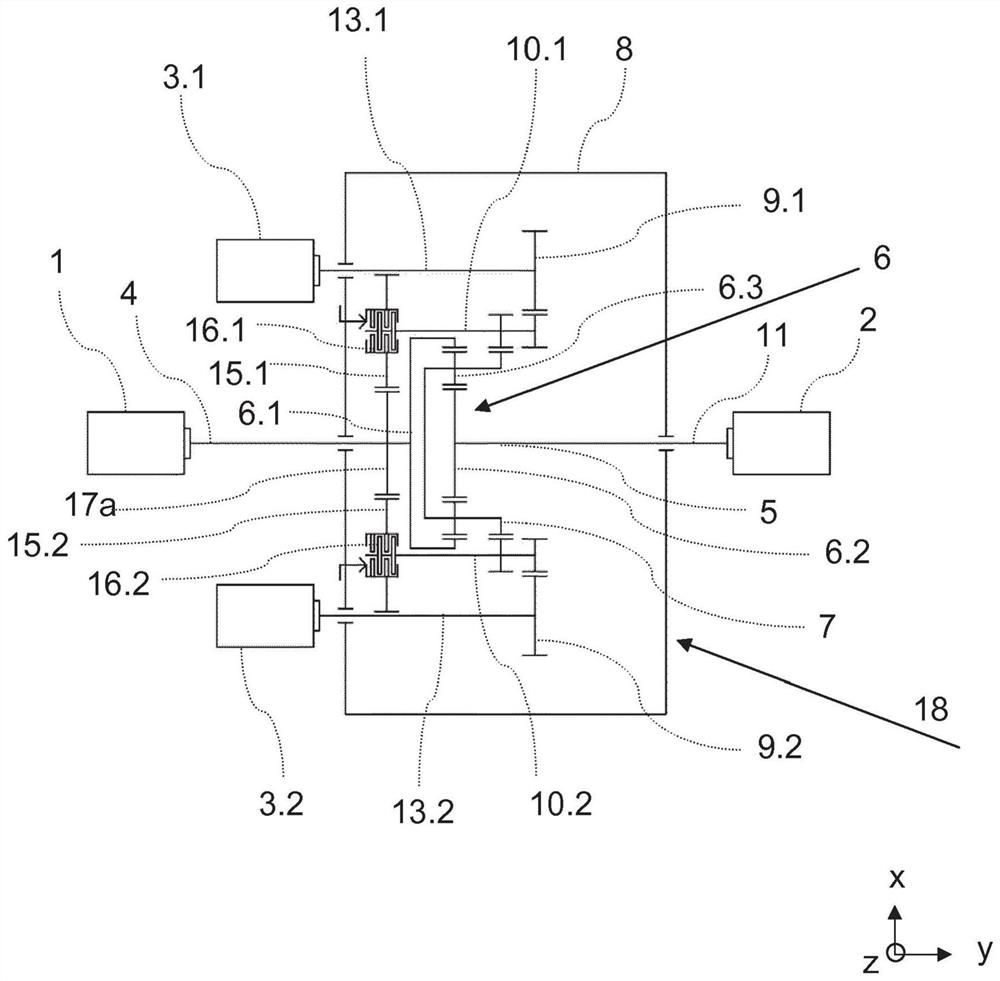

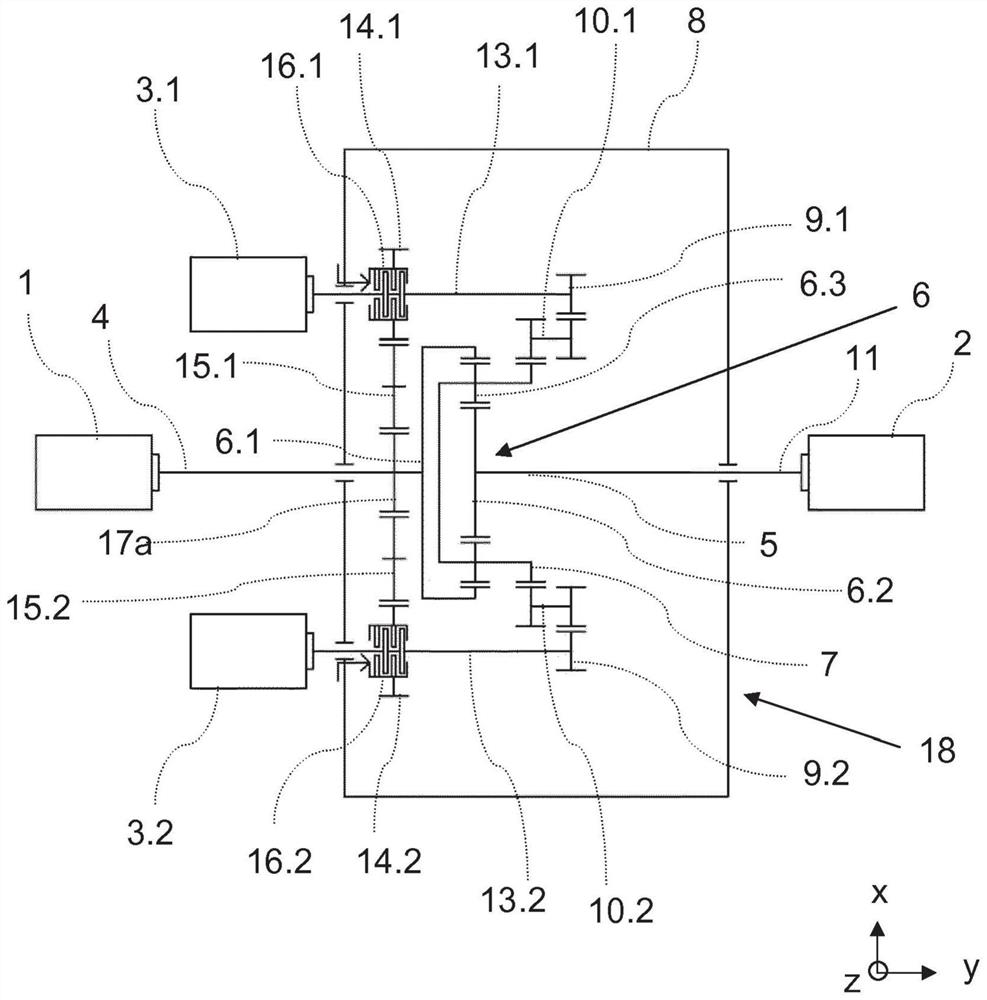

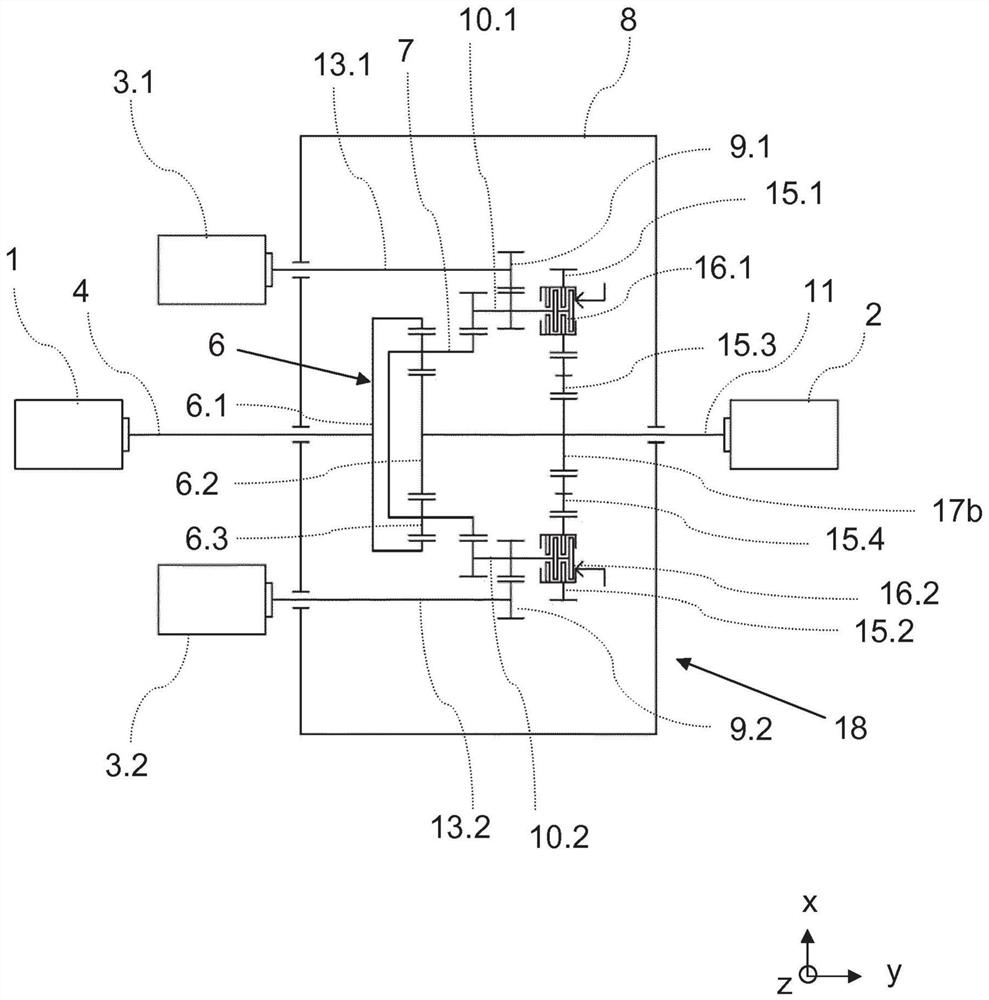

[0035] figure 1 The drive device according to the invention is shown in plan view, which is coupled to the work machine 2 via an output shaft 11 . The work machine 2 can be, for example, a pump, a compressor, a ventilator or a blower. The work machine can also be a belt drive or a mill or similar. Especially for work machines 2 with high power, it is especially important to have a high-efficiency drive. Due to the dimensions of the drive, it is also crucial that the required installation space is not too large.

[0036] The superposition gear 18 present in the drive unit has a housing 8 and includes the planetary gear 6 . The output shaft 5 of the planetary gear is at the same time the output shaft 11 of the superposition gear. The input shaft 4 connects the main drive machine 1 to the ring gear 6.1 of the planetary gear, and the output shaft 5 is coupled to the sun gear 6.2. The transmission connection between the ring gear 6.1 and the sun gear 6.2 is realized via the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com