A damping and sealing device for a high-power hydrogen-oxygen turbo pump

A technology of sealing device and turbo pump, which is applied to components of pumping device for elastic fluid, jet propulsion device, rocket engine device, etc. , the effect of reducing the circumferential velocity and increasing the logarithmic decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

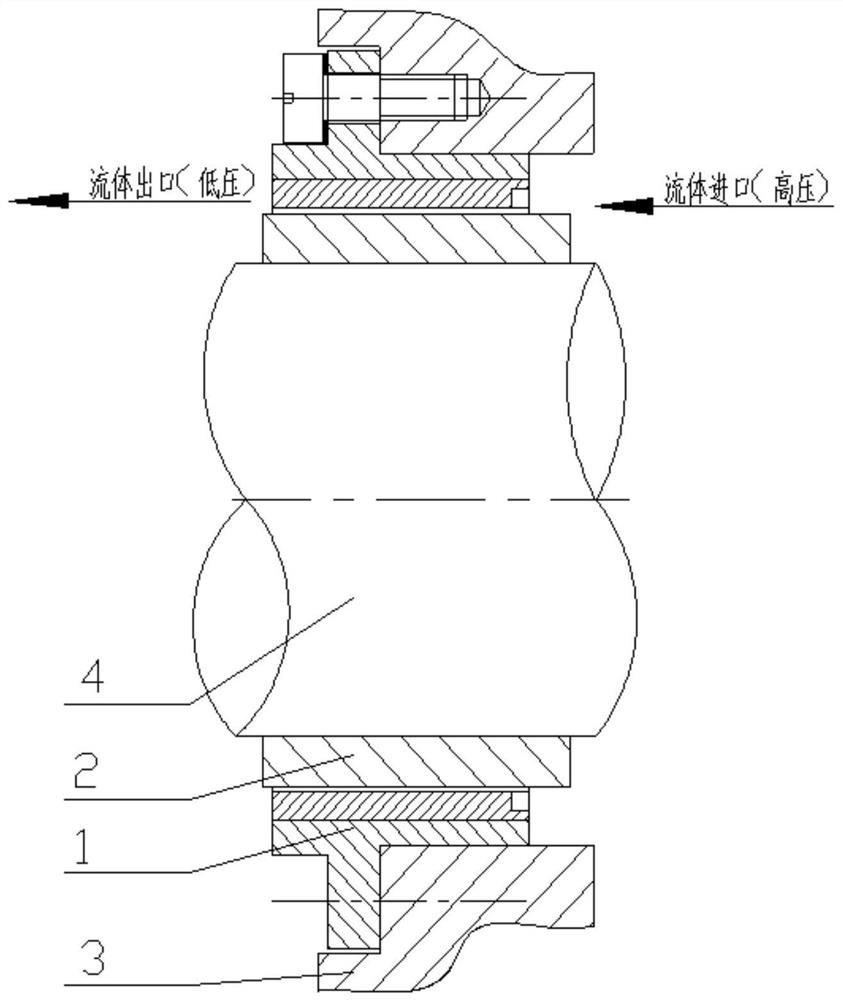

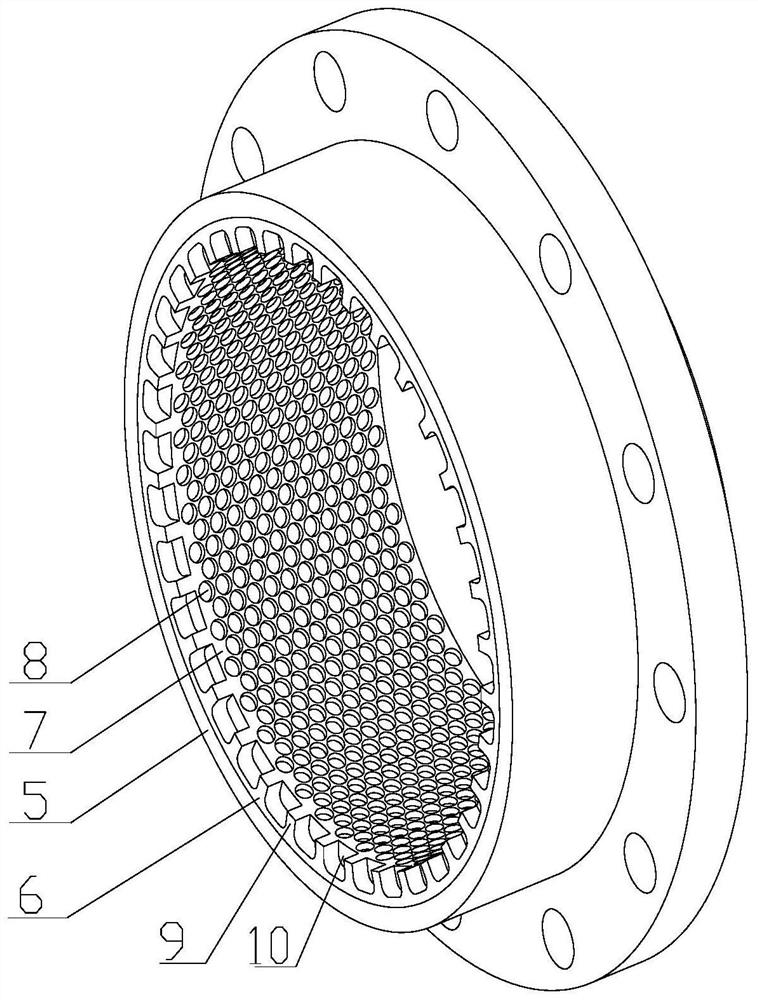

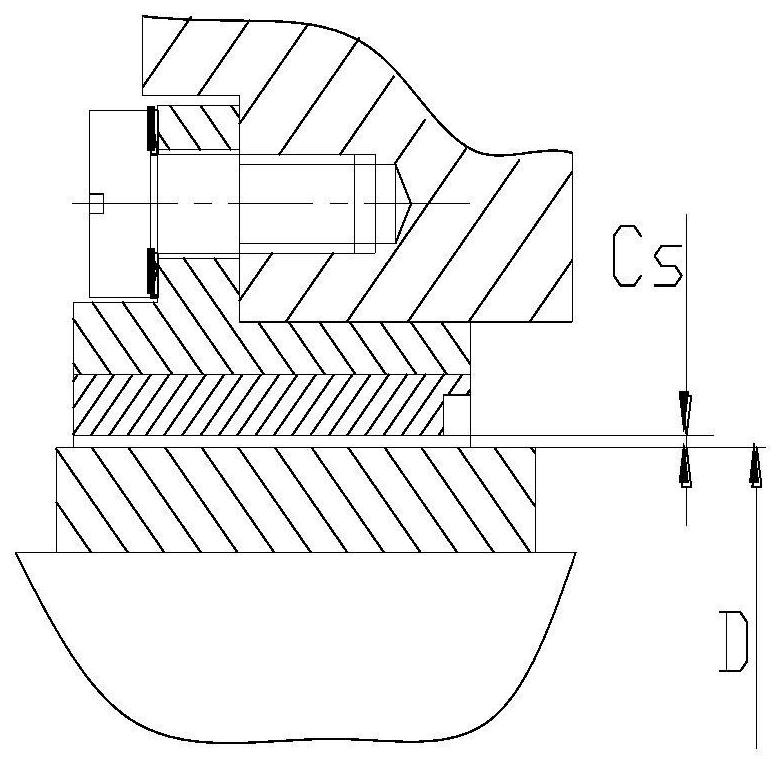

[0031] A low-temperature, high-speed, heavy-duty hydrogen-oxygen turbo pump damping and sealing device (that is, a damping and sealing device for a high-power hydrogen-oxygen turbo pump), which can be applied to the impeller shoulder of a cryogenic pump or the interstage seal of a multi-stage pump, Its structure is composed of a damping sealing assembly 1 and a sealing shaft sleeve 2 . The damping seal assembly 1 is installed on the turbo pump casing 3 through bolt connection, and is a stationary assembly. The shaft sleeve 2 is installed on the rotating shaft 4, and its two sides are respectively clamped by the shafting parts and rotate with the shaft. The schematic diagram of the damping sealing device is shown in figure 1 , the schematic diagram of the damping seal assembly is shown in figure 2 . Such as figure 1 As shown, the right side of the damping seal device is the high-pressure chamber in the pump, and the left side is the low-pressure chamber in the pump. The da...

Embodiment 2

[0039] A low-temperature pump impeller shoulder and a damping seal device between pump stages for high-speed liquid hydrogen and liquid oxygen turbo pumps. Its structure is composed of a static damping seal assembly 1 and a rotating seal bushing 2. For the assembly relationship, see figure 1As shown, the damping seal assembly 1 is assembled on the pump housing 3 of the hydrogen-oxygen turbo pump, and the sealing sleeve 2 is assembled on the rotor sleeve 2 of the turbo pump to rotate with the shaft at high speed.

[0040] The right side of the damping seal device is the high-pressure area of the pump chamber, and the left side is the low-pressure area of the pump chamber. The damping seal can not only limit the leakage rate of the medium inside the pump chamber, but also reduce the cross stiffness of the seal, improve the damping effect, suppress the vibration of the rotor, and improve Rotor stability.

[0041] The damping sealing assembly 1 is brazed by a stainless steel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com