Sensor calibration method

A calibration method and sensor technology, applied in the field of sensors, can solve problems such as time-consuming manpower, increased sensor calibration costs, troublesome sensor calibration methods, etc., and achieve the effects of simple calibration methods, improved calibration efficiency, and reduced calibration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

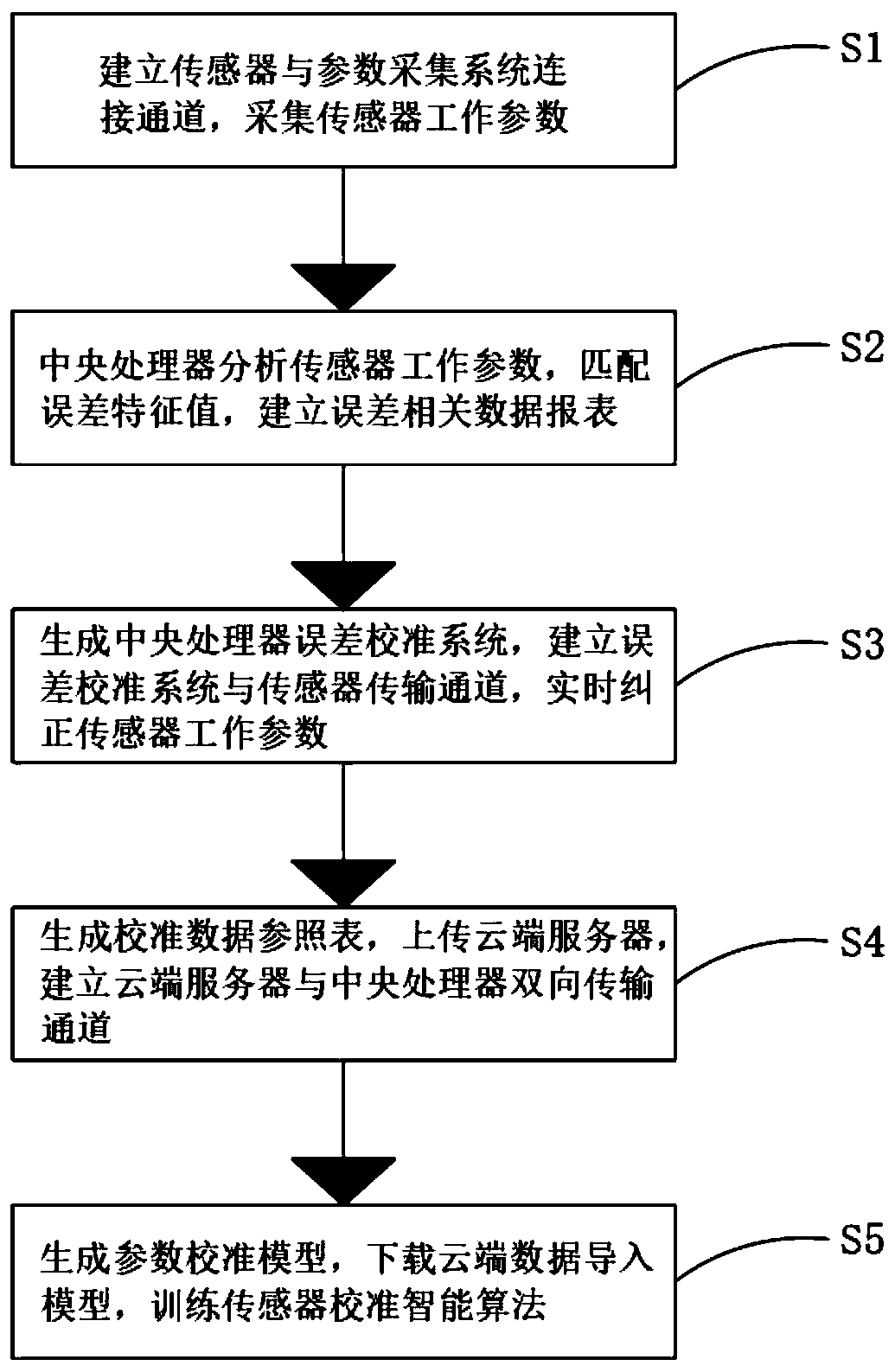

[0034] Such as figure 1 As shown, the embodiment of the present invention provides a sensor calibration method, including the following steps:

[0035] S1. Establish a connection channel between the sensor and the parameter acquisition system, and collect the working parameters of the sensor;

[0036] S2. The central processing unit analyzes the working parameters of the sensor, matches the characteristic value of the error, and establishes an error-related data report;

[0037] S3. Generate the error calibration system of the central processing unit, establish the error calibration system and the sensor transmission channel, and correct the sensor working parameters in real time;

[0038] S4. Generate a calibration data reference table, upload it to the cloud server, and establish a two-way transmission channel between the cloud server and the central processing unit;

[0039] S5. Generate a parameter calibration model, download the cloud data import model, and train the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com