Novel slotted disc type permanent magnet eddy current coupling

A permanent magnet eddy current, grooved disc technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electrical components, etc., can solve the problems of reducing the utilization efficiency of magnetic materials, increasing the heat dissipation burden of equipment, and increasing eddy current loss, etc. Achieve the effect of torque fluctuation reduction, reasonable spatial distribution, and reduction of torque fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

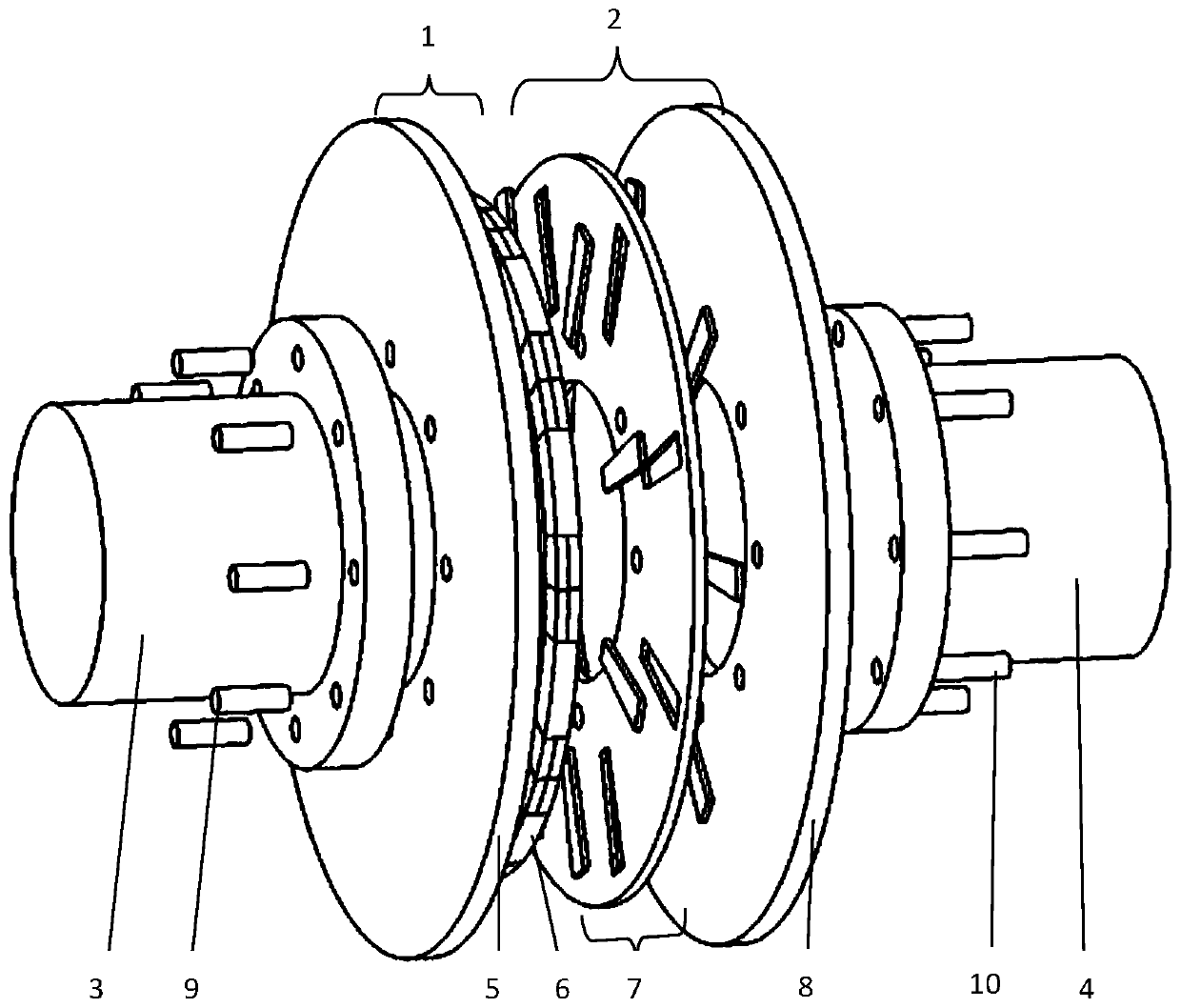

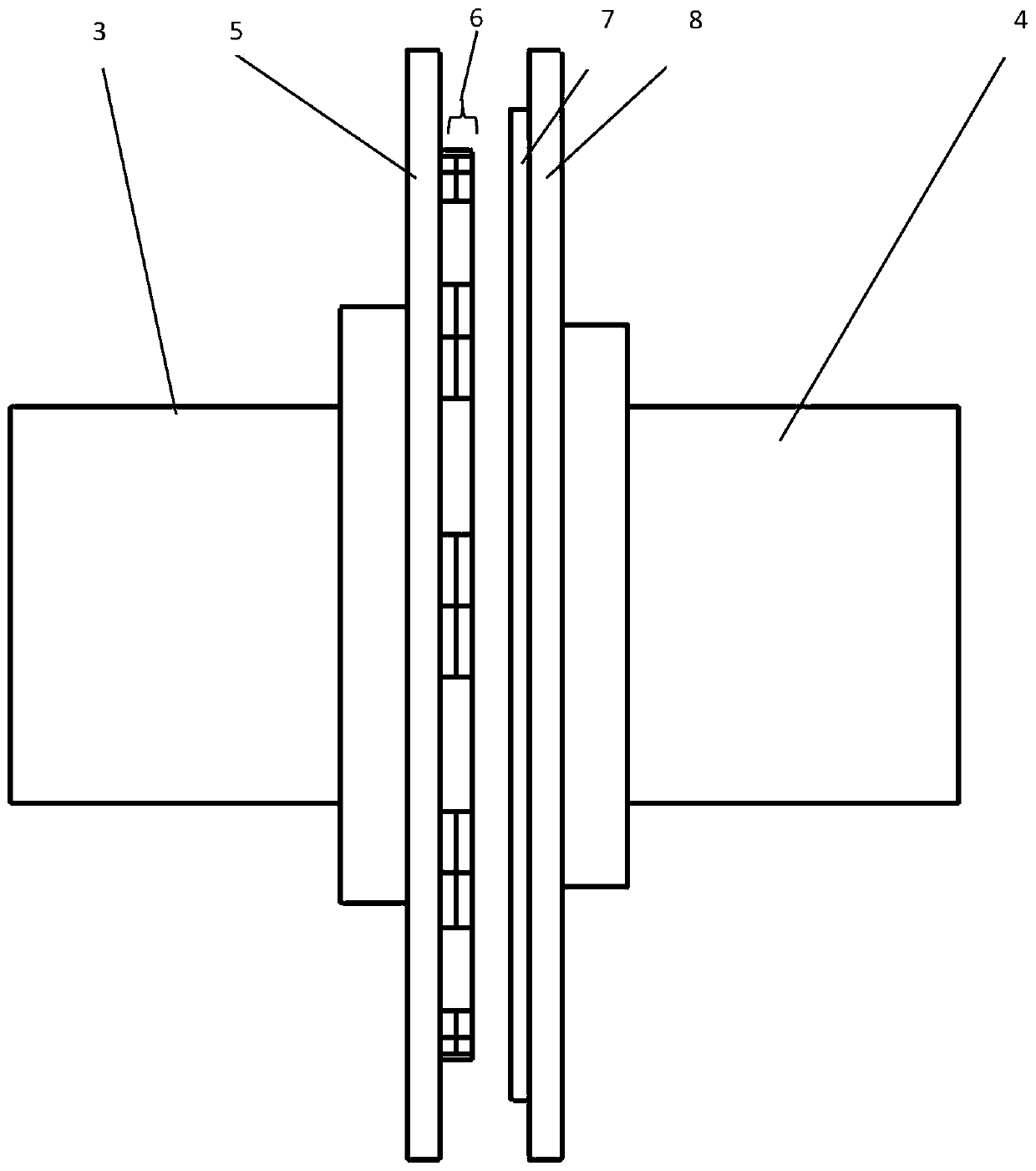

[0026] From figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 It can be seen that the slotted disc permanent magnet eddy current coupling of the present invention includes a driving disc 1, a driving shaft 3, a driven disc 2, and a driven shaft 4, and the driving disc 1 and the driving shaft 3 are coaxially arranged and connected to each other. , the driven disk 2 and the driven shaft 4 are coaxially arranged and connected, the driving disk 1 and the driven disk 2 are coaxially arranged, the driving disk 1 includes the back iron disk I5, the magnetic coil 6, the back iron disk I5 and the magnet The ring 6 is coaxially arranged, and the magnetic ring 6 is fixed on the inner surface of the back iron plate I5 opposite to the driven plate 2, and the back iron plate I5 and the driving shaft 3 are connected through the connecting column I9; the driven plate 2 includes an eddy current combination plate 7. The back iron plate Ⅱ8, the eddy current combination plate 7 and the...

Embodiment 2

[0031] From Figure 4 , Figure 5 , Figure 6It can be seen that, as a preferred mode of the present invention, the shapes and sizes of all grooves on the left end face of the vortex disk body 15 are the same, the depth of the grooves is less than the thickness of the eddy current disk body 15, and the shape and size of the left iron block 16 are the same as those of the vortex disk. The grooves on the left end surface of the body 15 have the same shape and size. The shape and size of all the grooves on the right end face of the swirl disc body 15 are the same, the depth of the groove is less than the thickness of the swirl disc body 15, the shape and size of the right iron block 17 are the same as the shape and size of the grooves on the right end face of the swirl disc body 15 same.

[0032] The left iron block 16 , the right iron block 17 and the swirl disc body 15 are fixed by bonding or clamping. As long as the stability of the connection between the left iron block 1...

Embodiment 3

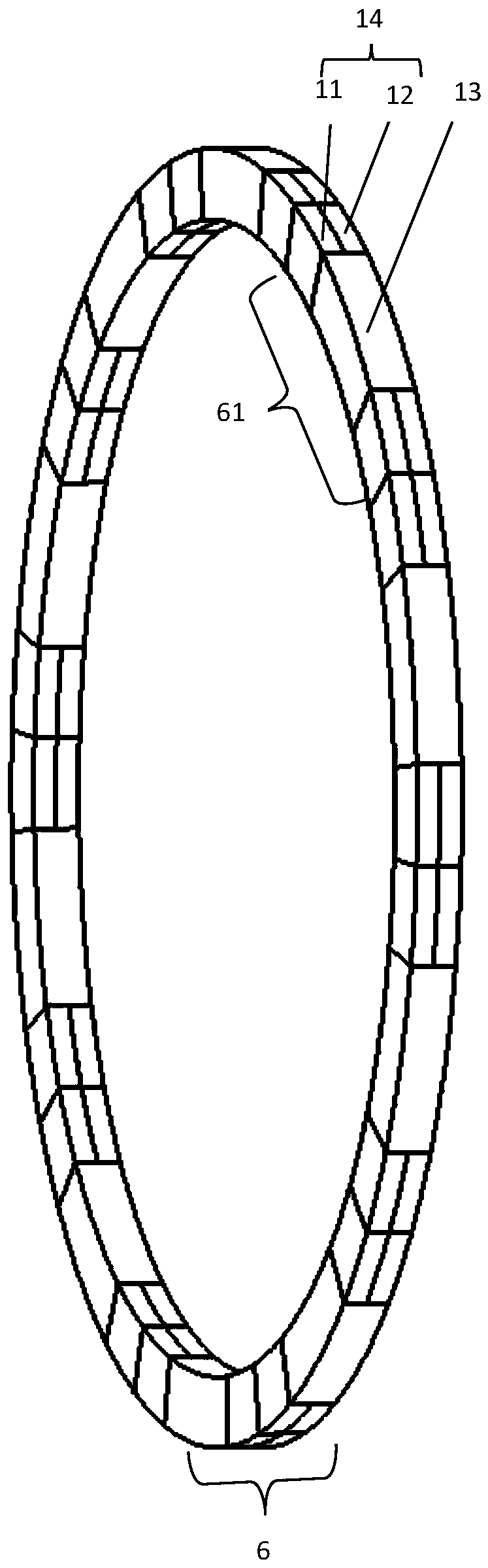

[0036] From image 3 , Figure 7 It can be seen that in the slotted disc permanent magnet eddy current coupling of the present invention: the magnetic coil 6 is formed into a ring by a plurality of mixed magnetic poles 61, and each mixed magnetic pole 61 is a fan ring structure with the same shape and size. The direction of the resultant magnetic field is along the axial direction of the drive disk 1 , and the direction of the resultant magnetic field of adjacent mixed magnetic poles 61 is opposite.

[0037] Wherein, each hybrid magnetic stage 61 comprises a magnetic block 13, a magnetic gathering unit 14 symmetrically arranged on the left and right sides of the magnetic block 13; The block 13 has the same thickness along the axial direction of the driving disk 1 , and the magnetization unit 14 and the magnetic block 13 have the same size along the radial direction of the driving disk 1 .

[0038] From Figure 7 It can be seen that the mixed magnetic poles in the magnetic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com