Thin plate-type heat pipe using pipe body and method for manufacturing same

A manufacturing method and thin-plate technology, applied in the direction of cooling/ventilation/heating transformation, electric solid-state devices, semiconductor devices, etc., to achieve the effect of accelerating thinning, increasing length and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

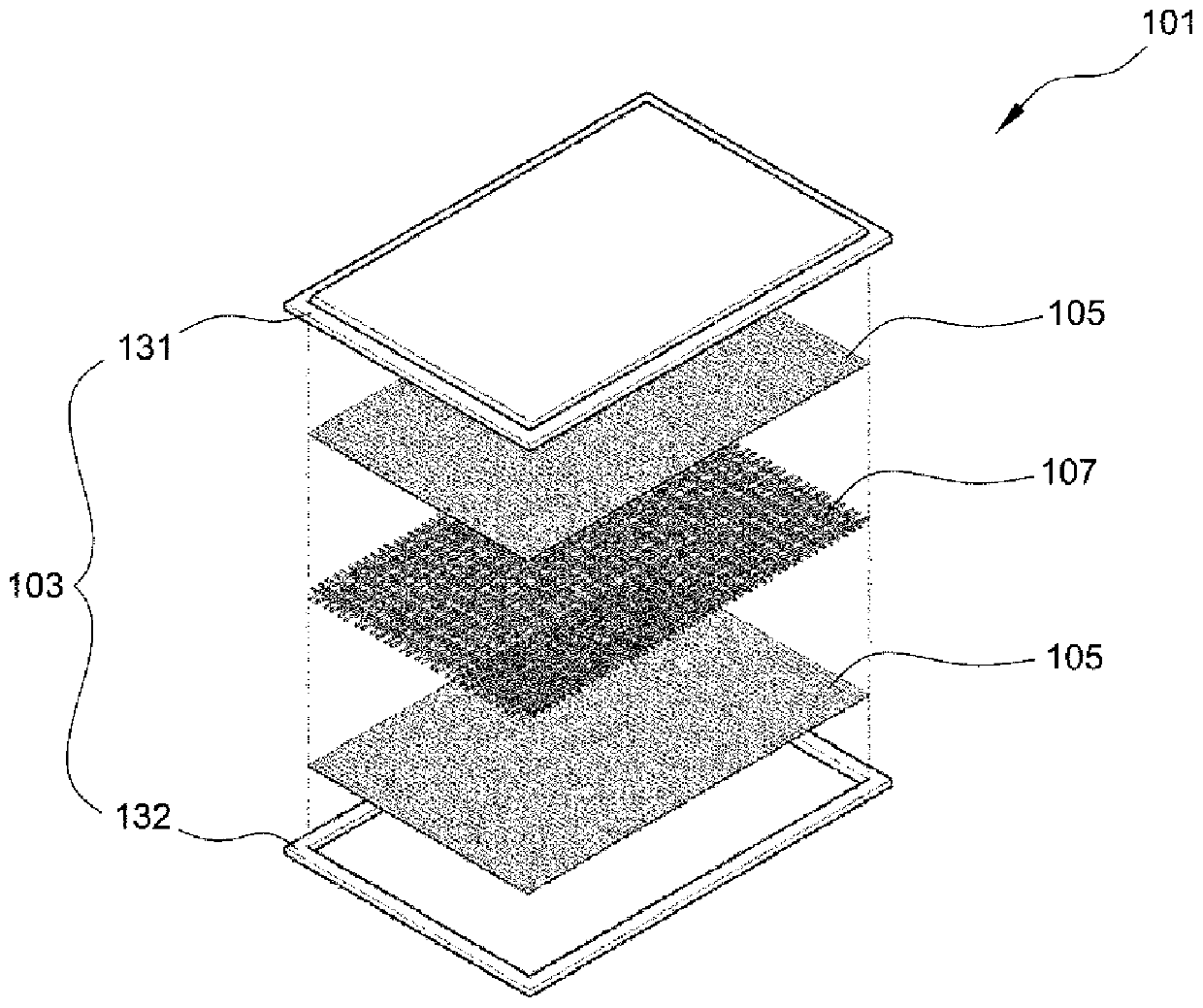

[0039] Hereinafter, a thin-plate heat pipe using a pipe body and a manufacturing method thereof according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

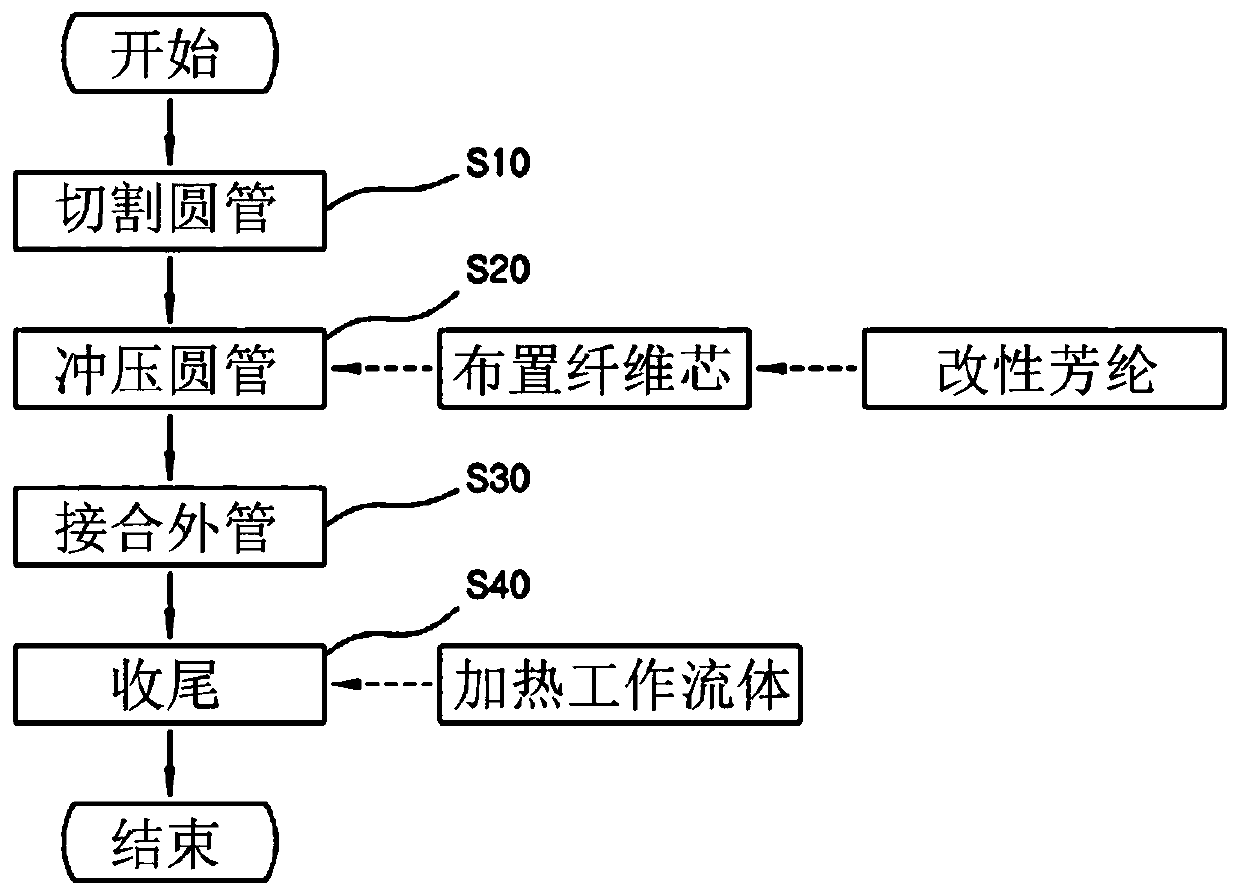

[0040] Such as figure 2 As shown, the heat pipe manufacturing method using the pipe body of the present invention generally includes: a cutting step S10 , a punching step S20 , a joining step S30 and a finishing step S40 .

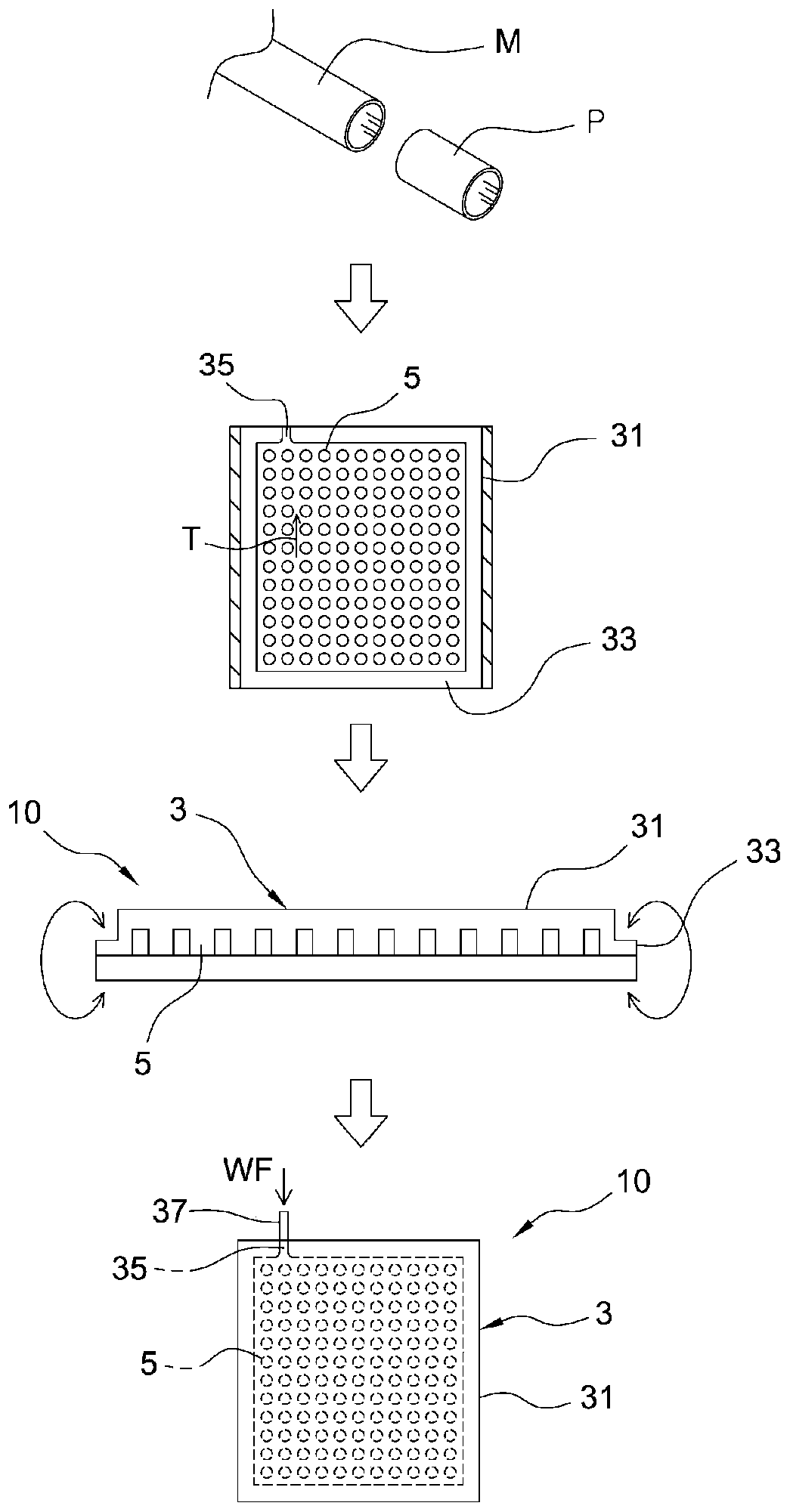

[0041] Such as figure 2 As shown, the cutting step S10 is a step of cutting a round pipe P from a metal pipe M. Such as image 3 As shown, the tubular metal pipe material M is cut to an appropriate length according to the outer pipe 31 constituting the casing 3 . Here, the round pipe P may be a closed-loop cross-sectional shape of various shapes such as a cylindrical pipe, an elliptical cylindrical pipe, and a square pipe. Then, if Figure 3 to Figure 5 As shown, the round pipe P is the outer pipe 31 . However, for the metal pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com