Film hole furrow irrigation method for saline-alkali land soil, and mulching film puncher

A technology of saline-alkali land and puncher, which is applied in botany equipment and methods, climate change adaptation, plant protection cover, etc. It can solve problems such as poor soil quality and shortage of irrigation water resources, so as to improve the uniformity of irrigation and improve the efficiency of agricultural production , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

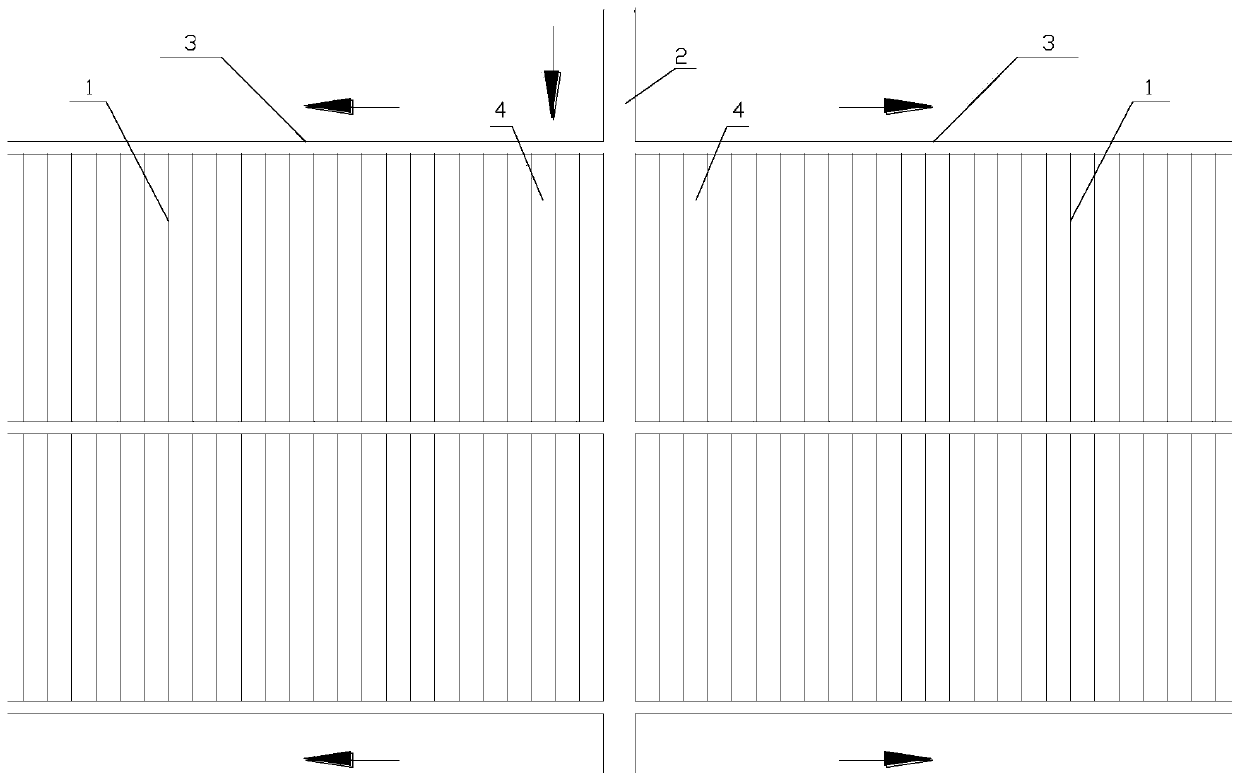

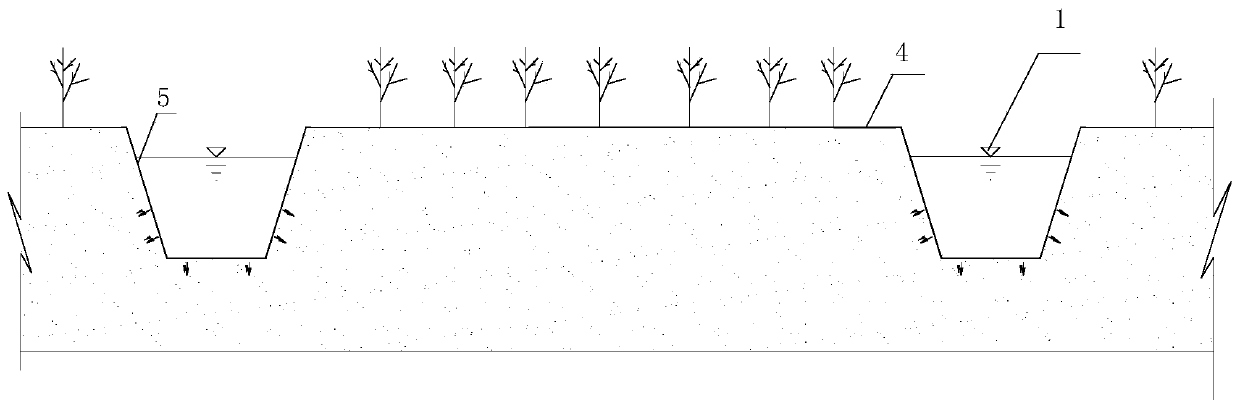

[0031] Embodiment 1: as figure 1 shown.

[0032] When the field is level, or when the subdivision is horizontal, the hairy canal 2 passes through a central axis of the subdivision, and the two sides of the canal 2 lead to multiple water delivery ditches 3 according to the length of the subdivision. Extending to the edge of the partition, the water delivery ditch 3 runs through multiple irrigation ditches 1, and the irrigation ditch 1 is the inter-ditch field ridge 4. The crops are planted on the inter-ditch field ridge 4, and the irrigation water is introduced from the hair ditch 2. The canal 2 flows into the water delivery ditch 3 , then flows into the irrigation ditch 1 , and finally penetrates into the field ridge 4 between the ditches to realize crop irrigation.

Embodiment 2

[0033] Embodiment 2: as figure 1 shown.

[0034] When the partition has a certain slope, and the slope is not greater than 5°, the hair canal 2 is located on the central axis of each partition along the slope direction, and the two sides of the hair canal 2 are dug through with multiple water delivery ditches 2 parallel to each other. The water delivery ditch 3 extends to the edge of the corresponding partition.

Embodiment 3

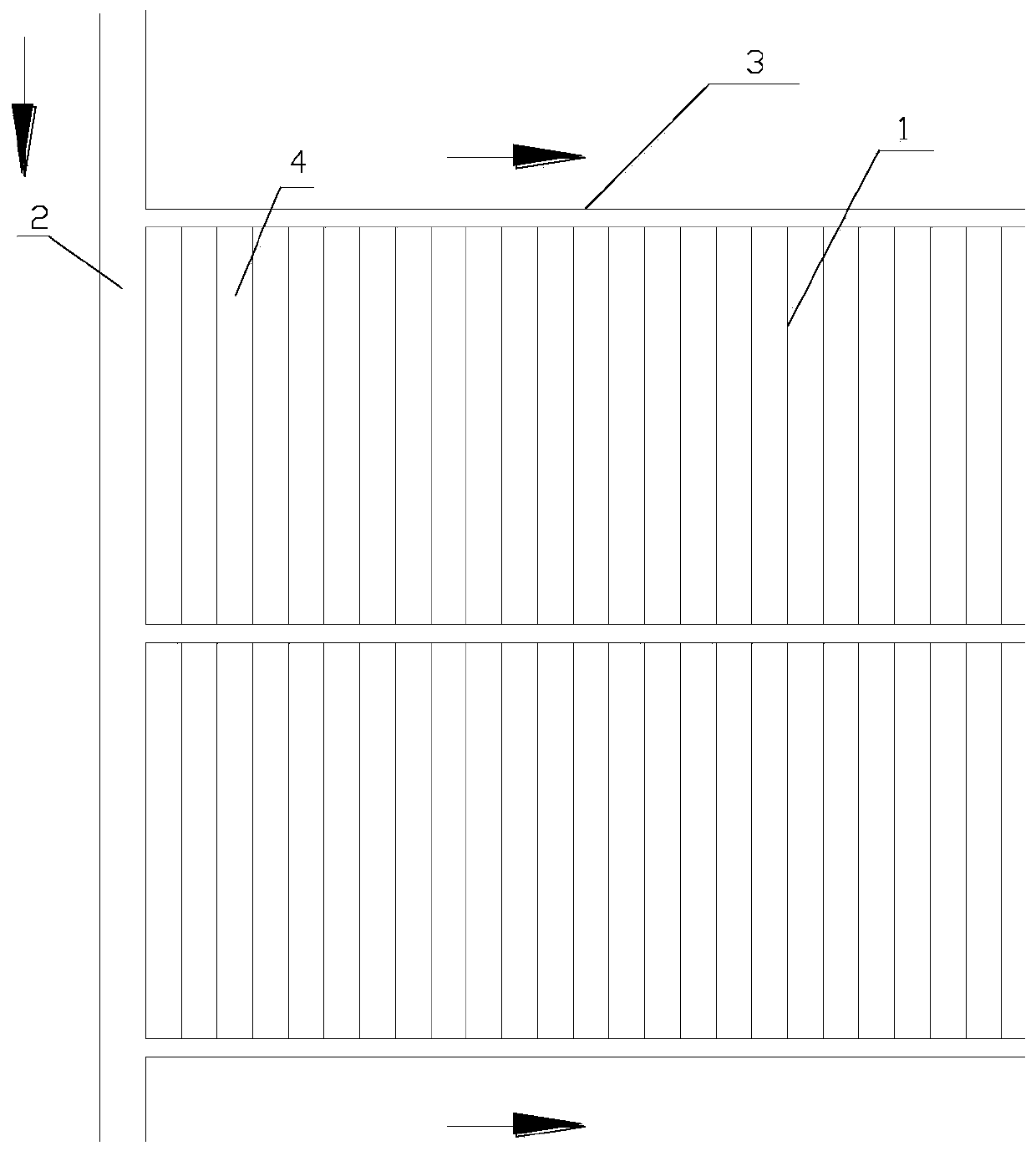

[0035] Embodiment 3: as figure 2 shown.

[0036] When the slope of the partition is greater than 5°, the hair canal 2 is set on the side of the slope of the partition, and a cross-block is set in the direction of the channel of the water delivery ditch 3, and the irrigation ditch 1 is set parallel to the slope contour line. Or it is set at an acute angle with the contour line of the slope, and the slope faces the downhill direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com