Stereoscopic warehouse for sheet material

A three-dimensional, sheet technology, applied in the field of storage, can solve the problems of easy rollover, large space occupation, low time efficiency, etc., and achieve the effect of saving storage space and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

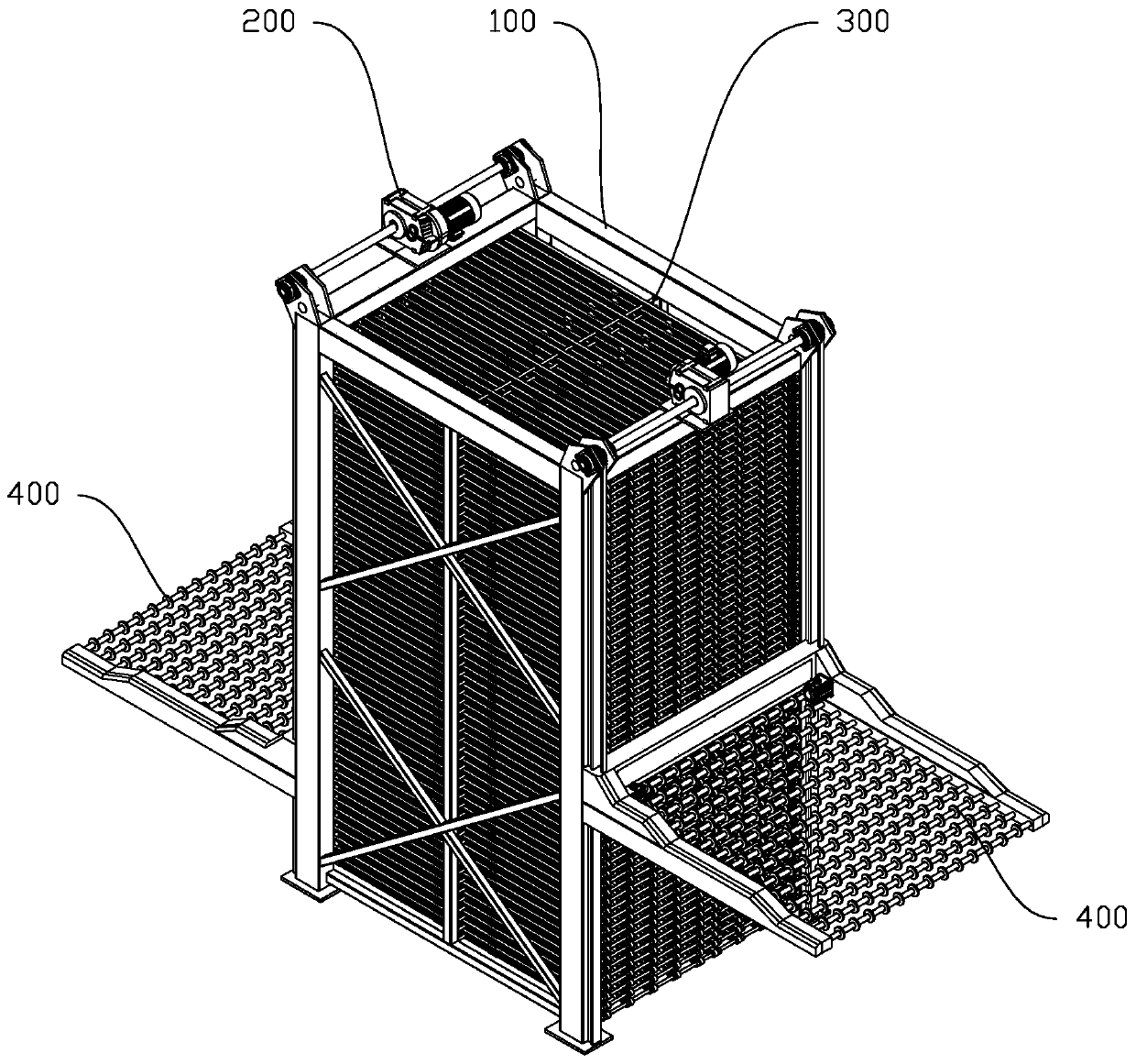

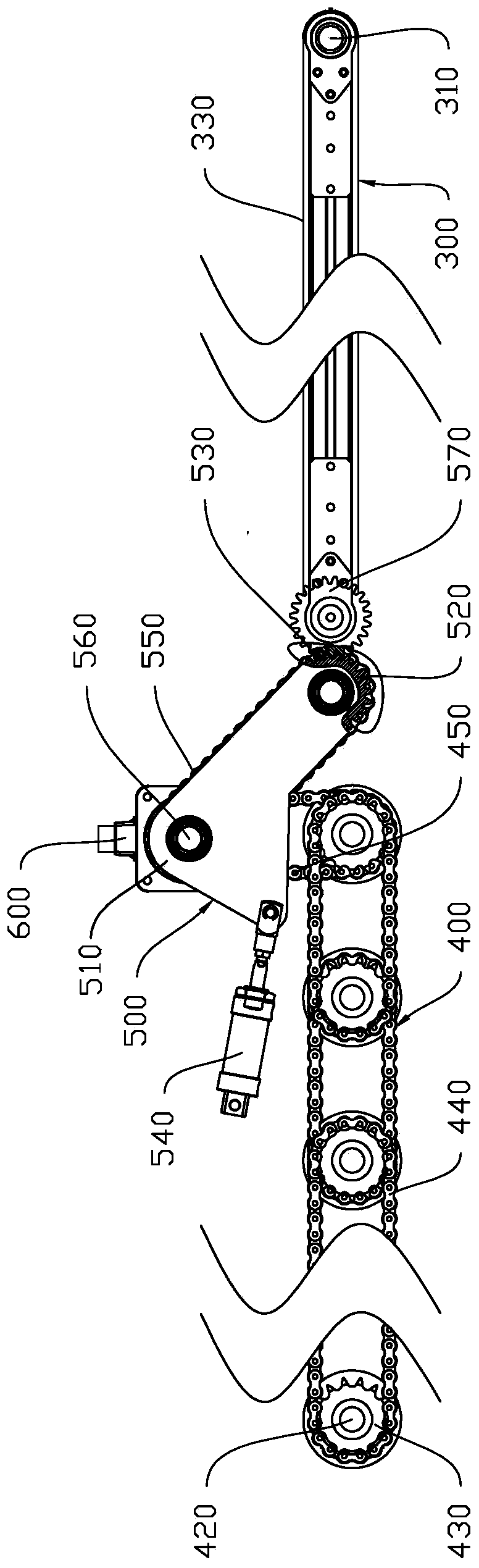

[0041] refer to figure 1 , Figure 8 As shown, the second example of the lifting mechanism 200: includes a second reduction motor 250, the second reduction motor 250 is installed on the conveying unit shelf 400, and the second reduction motor 250 is equipped with a gear 270; the rack 260 is vertically installed on the three-dimensional warehouse frame 100 and towards the conveying unit shelf 400, the second reduction motor 250 drives the gear 270 to rotate, so that the gear 270 moves on the rack 260, so that the conveying unit shelf 400 rises or falls.

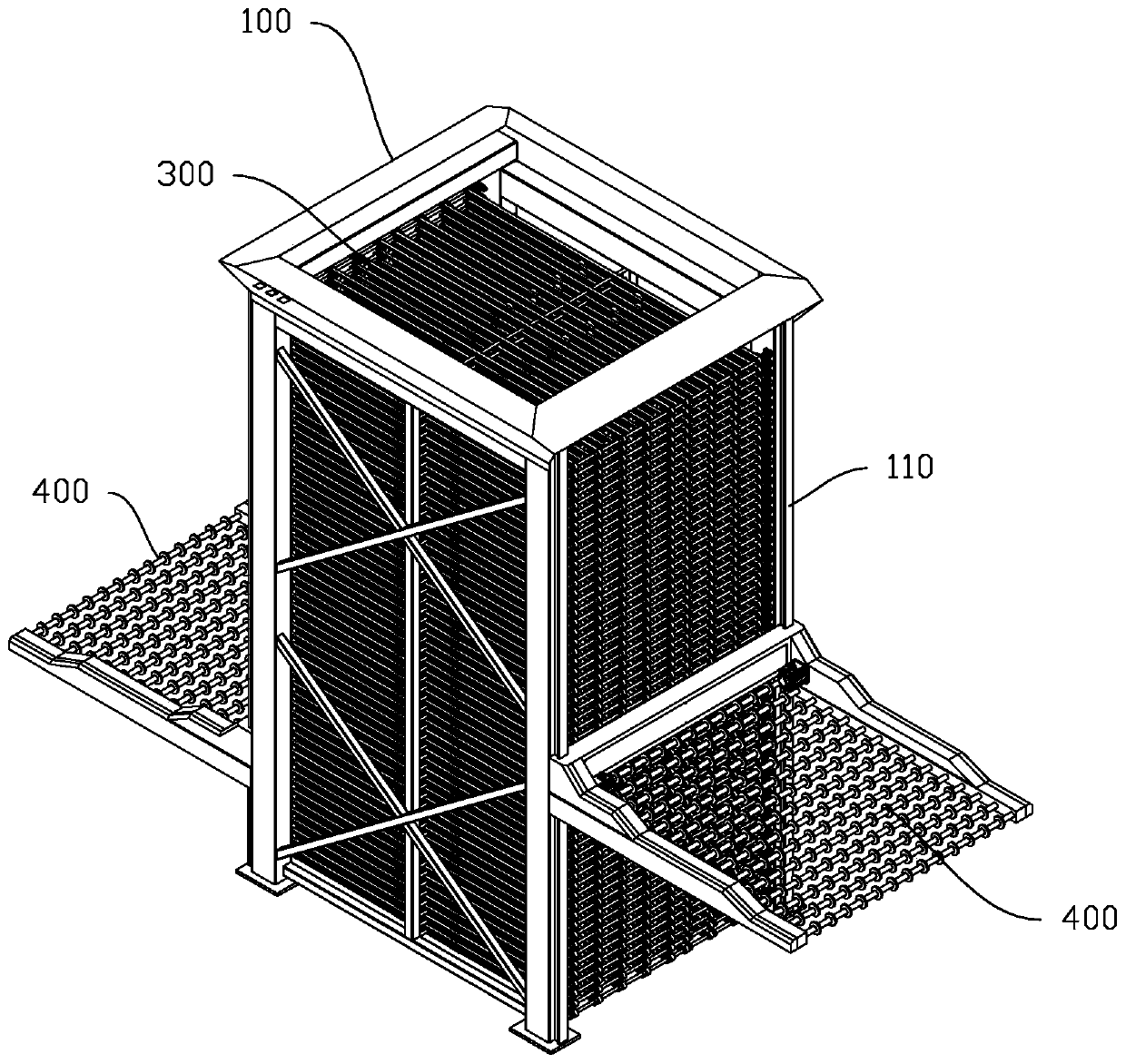

[0042] In order to further ensure smooth lifting, vertical slide rails 110 are provided on the three-dimensional warehouse frame 100 , and chute 470 that cooperates with the vertical slide rails 110 is provided on the conveying unit shelf 400 .

[0043] The above-mentioned power source 600 may adopt a servo motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com