Quality dividing agent for rapid phase separation of multiphase body, and preparation method thereof

A technology of phase separation and quality separation agent, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of slow quality separation, secondary pollution, poor effect, etc. High speed, reduced emissions, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

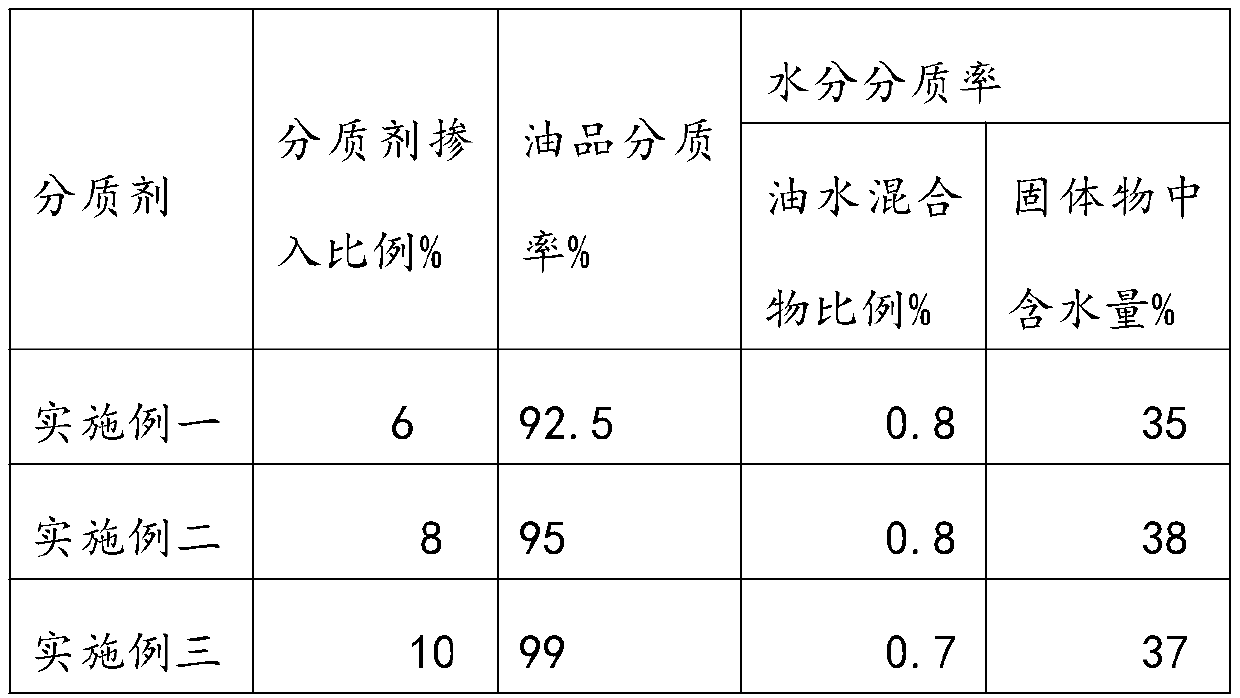

Embodiment 1

[0031] The components of the mass-separating agent used for rapid phase separation of heterogeneous bodies are mixed uniformly by dry method in the following parts by weight.

[0032] Iron and steel sintering plant desulfurization ash: 30 parts; power plant desulfurization ash: 30 parts; ironworks gas ash: 30 parts; dolomite: 9 parts; limestone: 9 parts; dispersant: 2 parts.

Embodiment 2

[0034] The components of the mass-separating agent used for rapid phase separation of heterogeneous bodies are mixed uniformly by dry method in the following parts by weight.

[0035] Iron and steel sintering plant desulfurization ash: 35 parts; power plant desulfurization ash: 25 parts; ironworks gas ash: 25 parts; dolomite: 7 parts; limestone: 7 parts; dispersant: 1 part.

Embodiment 3

[0037] The components of the mass-separating agent used for rapid phase separation of heterogeneous bodies are mixed uniformly by dry method in the following parts by weight.

[0038] Iron and steel sintering plant desulfurization ash: 35 parts; power plant desulfurization ash: 20 parts; ironworks gas ash: 30 parts; dolomite: 6 parts; limestone: 6 parts; dispersant: 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com