A kind of carboxylated nitrile rubber and preparation method thereof

A technology of carboxylated nitrile rubber and carboxylated nitrile, which is applied in the field of carboxylated nitrile rubber and its preparation, can solve the problems of poor reactivity, easy to scorch, difficult to modify properties, etc., and achieve moderate vulcanization speed, vulcanization and crosslinking The effect of high precision and high response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

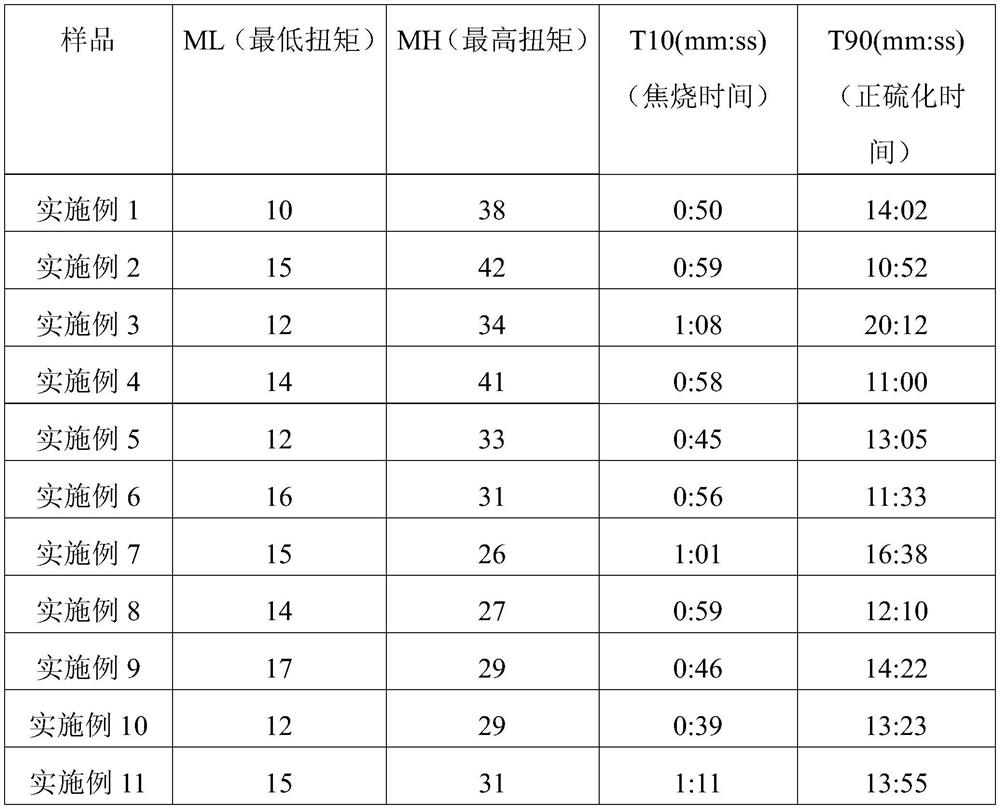

Examples

Embodiment 1

[0040] Take 100 parts of carboxylated nitrile rubber LANXESS X146, 50 parts of N330 carbon black, 3 parts of glycerol, 2 parts of DCC, 1 part of DMAP, and 3 parts of 264 anti-aging agent. Control the temperature at 30-50°C. After the mixing is completed, the mixed rubber is placed at room temperature for 4 hours, and then vulcanized by a flat vulcanizing machine at a vulcanization temperature of 140°C and a vulcanization time of 40 minutes to obtain a product.

Embodiment 2

[0042] Take 100 parts of carboxylated nitrile rubber LANXESS X146, 100 parts of N330 carbon black, 5 parts of glycerol, 5 parts of DCC, 3 parts of DMAP, and 3 parts of 264 anti-aging agent. During the process, the temperature is controlled at 30-50°C. After the mixing is completed, the mixed rubber is placed at room temperature for 8 hours, and then vulcanized by a flat vulcanizer at a vulcanization temperature of 150°C and a vulcanization time of 60 minutes. That is, a product is obtained.

Embodiment 3

[0044] Take 100 parts of carboxylated nitrile rubber LANXESS X146, 80 parts of N550 carbon black, 3 parts of glycerol, 4 parts of DCC, 2 parts of DMAP, and 5 parts of 264 anti-aging agent. During the process, the temperature is controlled at 30-50°C. After the mixing is completed, the mixed rubber is placed at room temperature for 4 hours, and then vulcanized by a flat vulcanizer at a vulcanization temperature of 120°C and a vulcanization time of 35 minutes. That is, a product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com