A kind of amidated vulcanized carboxylated nitrile rubber and preparation method thereof

A technology of carboxylated nitrile rubber and carboxylated nitrile, applied in the field of amidation vulcanized carboxylated nitrile rubber and its preparation, to achieve high reaction speed and moderate vulcanization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

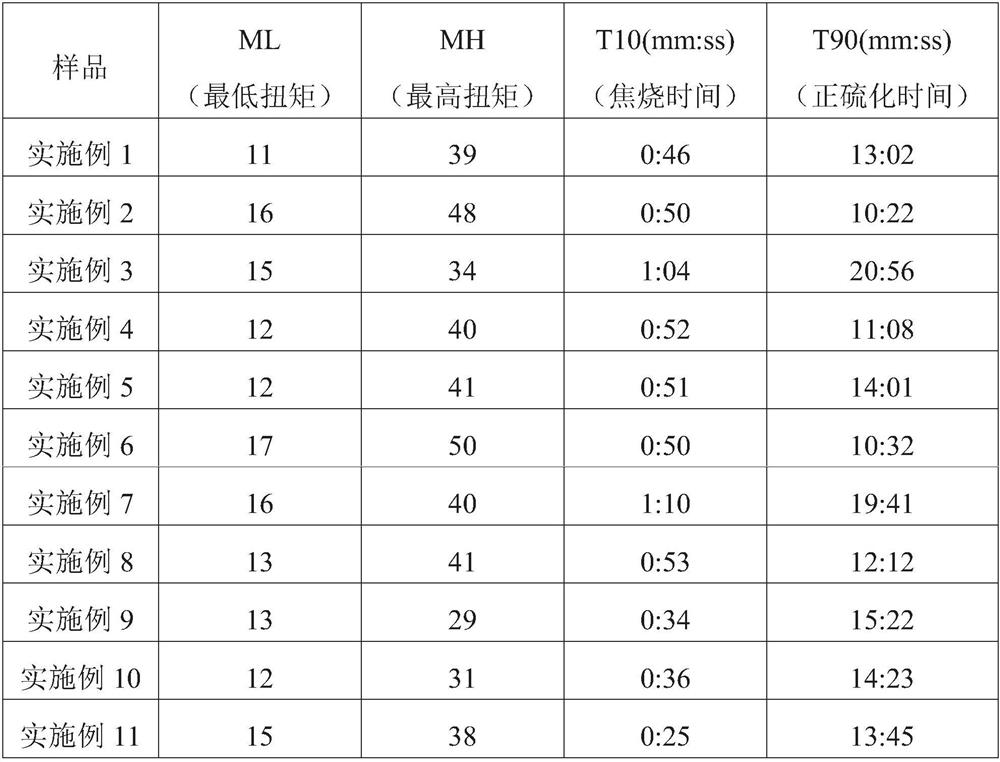

Examples

Embodiment 1

[0037] Mix 100 parts of carboxylated nitrile rubber Zeon N632S, 50 parts of N330 carbon black, 3 parts of hexamethylenediamine, 2 parts of DCC, 1 part of DMAP, and 3 parts of 264 anti-aging agent using an open mixer for 20 minutes until uniform, and control the mixing process The temperature is 30-50°C. After the mixing is completed, the mixed rubber is placed at room temperature for 4 hours, and then vulcanized by a flat vulcanizing machine at a vulcanization temperature of 140°C and a vulcanization time of 40 minutes to obtain a product.

Embodiment 2

[0039] Take 100 parts of carboxylated nitrile rubber LANXESS X146, 100 parts of N330 carbon black, 5 parts of hexamethylenediamine, 5 parts of DCC, 3 parts of DMAP, and 3 parts of 264 anti-aging agent. During the process, the temperature is controlled at 30-50°C. After the mixing is completed, the mixed rubber is placed at room temperature for 8 hours, and then vulcanized by a flat vulcanizer at a vulcanization temperature of 150°C and a vulcanization time of 60 minutes. That is, a product is obtained.

Embodiment 3

[0041] Take 100 parts of carboxylated nitrile rubber LANXESS X146, 80 parts of N550 carbon black, 3 parts of hexamethylenediamine, 4 parts of DCC, 2 parts of DMAP, and 5 parts of 264 anti-aging agent. During the process, the temperature is controlled at 30-50°C. After the mixing is completed, the mixed rubber is placed at room temperature for 4 hours, and then vulcanized by a flat vulcanizer at a vulcanization temperature of 120°C and a vulcanization time of 35 minutes. That is, a product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com