A low-smoke, low-toxicity, halogen-free, flame-retardant EPDM vibration-damping rubber material

A technology of EPDM rubber and EPDM, which is used in the field of vibration reduction and noise reduction to achieve the effects of good resilience, improved flame retardant effect and moderate vulcanization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation process of the low-smoke, low-toxicity, halogen-free flame-retardant EPDM vibration-damping rubber material of the present invention:

[0027] (1) Mixing: Masticate EPDM rubber 5 to 8 times, and mix according to the order of active agent, anti-aging agent, flame retardant, carbonation agent, carbon black and plasticizer, vulcanizing agent and accelerator.

[0028] (2) Thin-pass film out: Thin-pass the mixed rubber 8 to 10 times, and film out.

[0029] According to the needs, put the released film into the mold, heat and pressurize it for vulcanization, and then it can be processed into the required elastic through-cabin pipe fittings and other products. The vulcanization condition is 15-20MPa, 165±5℃, and the time is 20min.

[0030] Table 1 is a specific embodiment, and the parts in the embodiments are parts by mass.

[0031] Table 1

[0032]

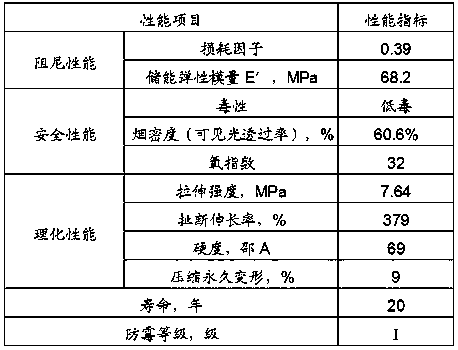

[0033] Table 2 is the main performance index of specific embodiment 1.

[0034] Table 2

[0035]

Embodiment 2

[0037] The preparation process of the low-smoke, low-toxicity, halogen-free flame-retardant EPDM vibration-damping rubber material of the present invention:

[0038] (1) Mixing: Masticate EPDM rubber 5 to 8 times, and mix according to the order of active agent, anti-aging agent, flame retardant, carbonation agent, carbon black and plasticizer, vulcanizing agent and accelerator.

[0039] (2) Thin-pass film out: Thin-pass the mixed rubber 8 to 10 times, and film out.

[0040] According to the needs, put the released film into the mold, heat and pressurize it for vulcanization, and then it can be processed into the required elastic through-cabin pipe fittings and other products. The vulcanization condition is 15-20MPa, 165±5℃, and the time is 20min.

[0041] Table 3 is a specific example, and the parts in the examples are parts by mass.

[0042] table 3

[0043]

[0044] Table 4 is the main performance index of specific embodiment 2.

[0045] Table 4

[0046]

Embodiment 3

[0048] The preparation process of the low-smoke, low-toxicity, halogen-free flame-retardant EPDM vibration-damping rubber material of the present invention:

[0049] (1) Mixing: Masticate EPDM rubber 5 to 8 times, and mix according to the order of active agent, anti-aging agent, flame retardant, carbonation agent, carbon black and plasticizer, vulcanizing agent and accelerator.

[0050] (2) Thin-pass film out: Thin-pass the mixed rubber 8 to 10 times, and film out.

[0051] According to the needs, put the released film into the mold, heat and pressurize it for vulcanization, and then it can be processed into the required elastic through-cabin pipe fittings and other products. The vulcanization condition is 15-20MPa, 165±5℃, and the time is 20min.

[0052] Table 5 is a specific embodiment, and the parts in the embodiments are parts by mass.

[0053] table 5

[0054]

[0055] Table 6 is the main performance index of specific embodiment 3.

[0056] Table 6

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com