High temperature resistant nitrile rubber and its application, non-marking segmental vulcanization method of sealing rubber products and main drive sealing ring

A technology of nitrile rubber and sealing rubber, applied in the rubber field, can solve the problems of insufficient reliability of sealing performance, easy entry of foreign objects on the sealing surface, severe vibration, etc., and achieve excellent low compression set performance, excellent wear resistance, Mooney Low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

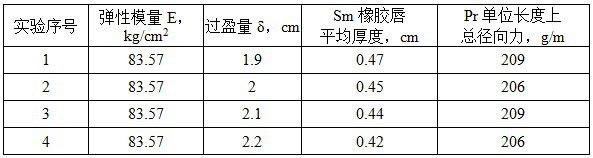

Examples

Embodiment 1

[0044] This embodiment provides a high temperature resistant nitrile rubber, the raw material composition of which is shown in Table 1.

[0045] Table 1

[0046]

[0047] Wherein, composite carbon black is the combination of fine-grained carbon black and coarse-grained carbon black, fine-grained carbon black is N220, and coarse-grained carbon black is N660, and the respective content of the two is 33 parts, 33 parts, two The weight ratio of the two is 1:1;

[0048] In the composite antiaging agent, the weight ratio of antiaging agent 4010NA, antiaging agent 4020, antiaging agent 246, antiaging agent TMQ and antiaging agent MB is 1:1:1:1:1;

[0049]In the composite tackifying resin, the weight ratio of coumarone resin, SP-1068 resin and phenolic resin is 1:1:1;

[0050] In the compound plasticizer, the weight ratio of plasticizer DOS and plasticizer DBP is 2:1;

[0051] In the composite accelerator, the weight ratio of accelerator DTDM, accelerator DM, and accelerator TMT...

Embodiment 2

[0060] This embodiment provides a high temperature resistant nitrile rubber, the raw material composition of which is shown in Table 2.

[0061] Table 2

[0062]

[0063] Wherein, composite carbon black is the combination of fine-grained carbon black and coarse-grained carbon black, fine-grained carbon black is N330, and coarse-grained carbon black is N550, and the respective contents of the two are respectively 34 parts, 34 parts, two The weight ratio of the two is 1:1;

[0064] In the composite antiaging agent, the weight ratio of antiaging agent 4010NA, antiaging agent 4020, antiaging agent 246, antiaging agent TMQ and antiaging agent MB is 1:1:1:1:1;

[0065] In the composite tackifying resin, the weight ratio of coumarone resin, SP-1068 resin and phenolic resin is 1:1:1;

[0066] In the compound plasticizer, the weight ratio of plasticizer DOS and plasticizer DBP is 2:1;

[0067] In the composite accelerator, the weight ratio of accelerator DTDM, accelerator DM, and...

Embodiment 3

[0076] This embodiment provides a high temperature resistant nitrile rubber, the raw material composition of which is shown in Table 3.

[0077] table 3

[0078]

[0079] Wherein, composite carbon black is the combination of fine-grained carbon black and coarse-grained carbon black, fine-grained carbon black is N220, and coarse-grained carbon black is N774, and the respective contents of the two are respectively 32.5 parts, 32.5 parts, two The weight ratio of the two is 1:1;

[0080] In the composite antiaging agent, the weight ratio of antiaging agent 4010NA, antiaging agent 4020, antiaging agent 246, antiaging agent TMQ and antiaging agent MB is 1:1:1:1:1;

[0081] In the composite tackifying resin, the weight ratio of coumarone resin, SP-1068 resin and phenolic resin is 1:1:1;

[0082] In the compound plasticizer, the weight ratio of plasticizer DOS and plasticizer DBP is 2:1;

[0083] In the composite accelerator, the weight ratio of accelerator DTDM, accelerator DM,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com