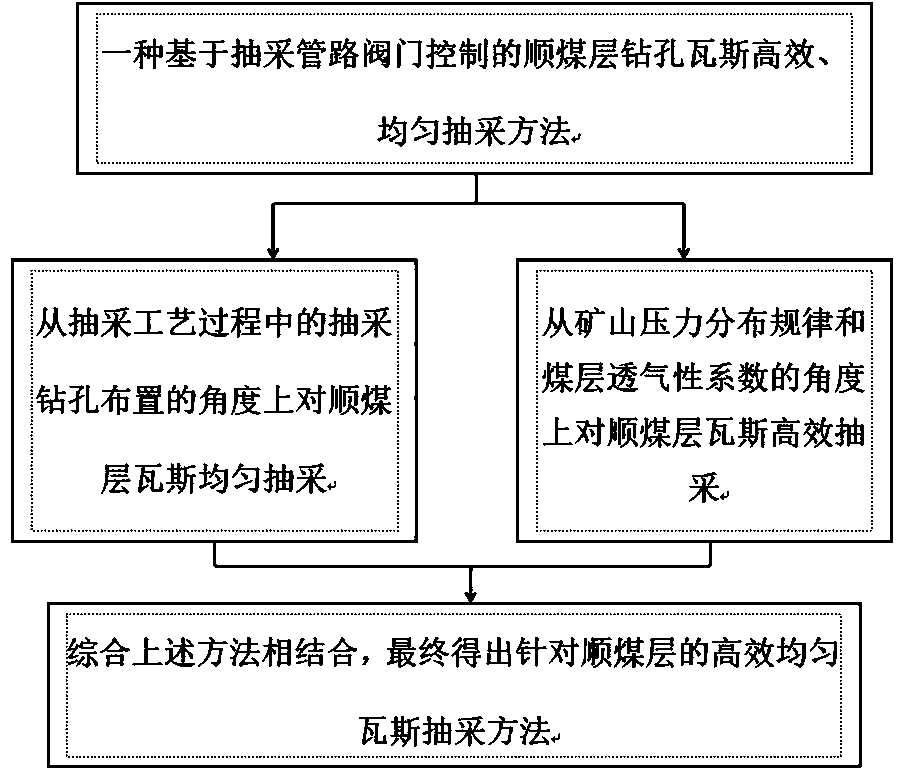

Gas extraction method through drilling along coal seam on basis of extraction pipeline valve control

A technology for drainage drilling and gas drainage, which is used in gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of uneven and inefficient gas drainage along the coal seam, and achieve uniform and efficient drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the present invention, a method of drilling gas drainage along the coal seam based on the valve control of the drainage pipeline is implemented in the following steps:

[0024] 1. From the point of view of the drainage borehole layout in the drainage process, the gas is evenly extracted along the coal seam

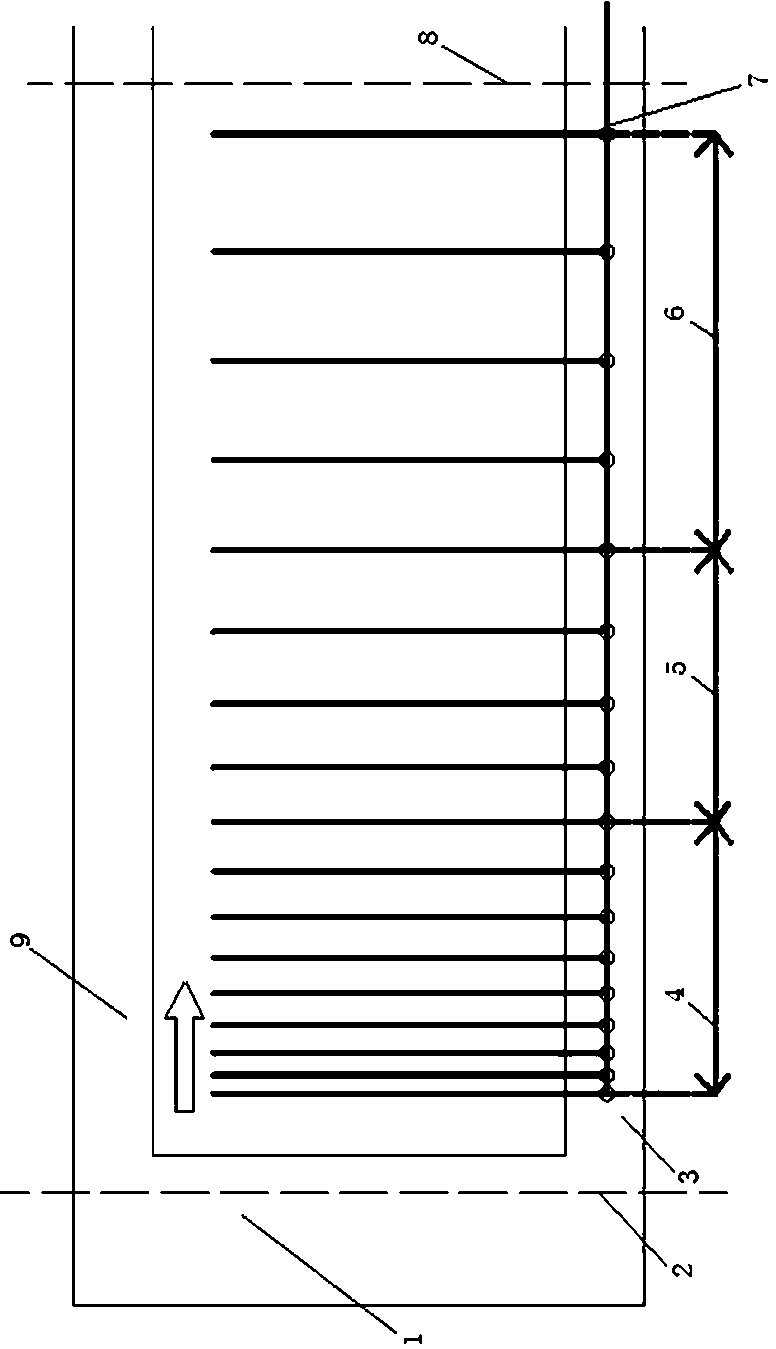

[0025] a. Start to excavate the air inlet roadway 3 and the air return roadway 9 from the position of the stoppage line 8 of the coal seam. With the advancement of the excavation working face, arrange the extraction boreholes and carry out the extraction. When the excavation reaches the coal seam opening 2, the drainage drilling arrangement is completed.

[0026] b. Adjust the extraction pipeline control valve 7 near the stop line 8, reduce the extraction negative pressure by adjusting the extraction pipeline control valve 7, and at the same time adjust the extraction pipeline control valve adjacent to the cut-off hole 2 7. Make the drainage negative pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com