Vacuum plugboard valve testing device

A technology of vacuum plug-in board and test device, which is applied in the direction of measuring device, mechanical valve test, fluid tightness test, etc., can solve the problems of limited use range and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

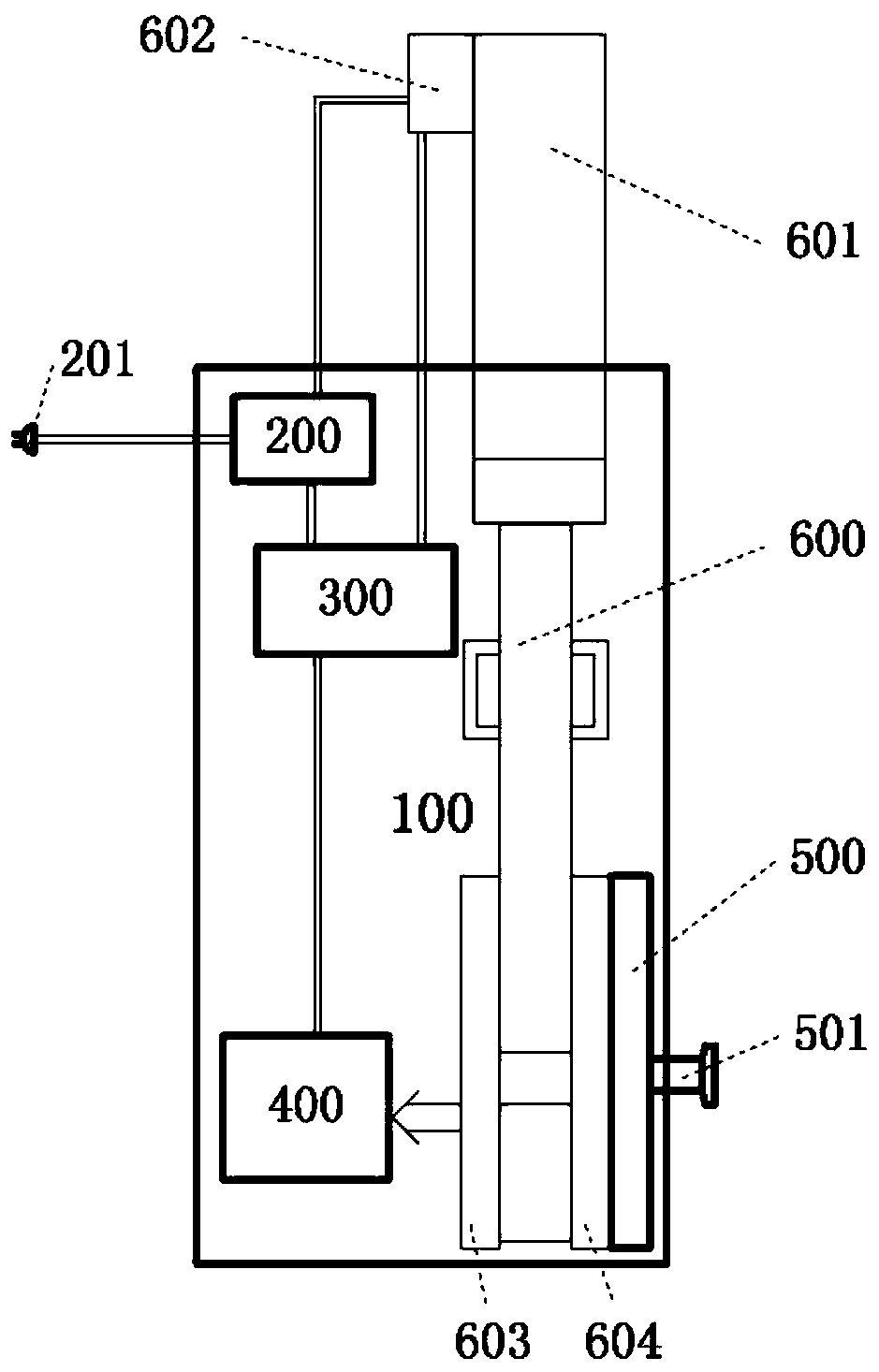

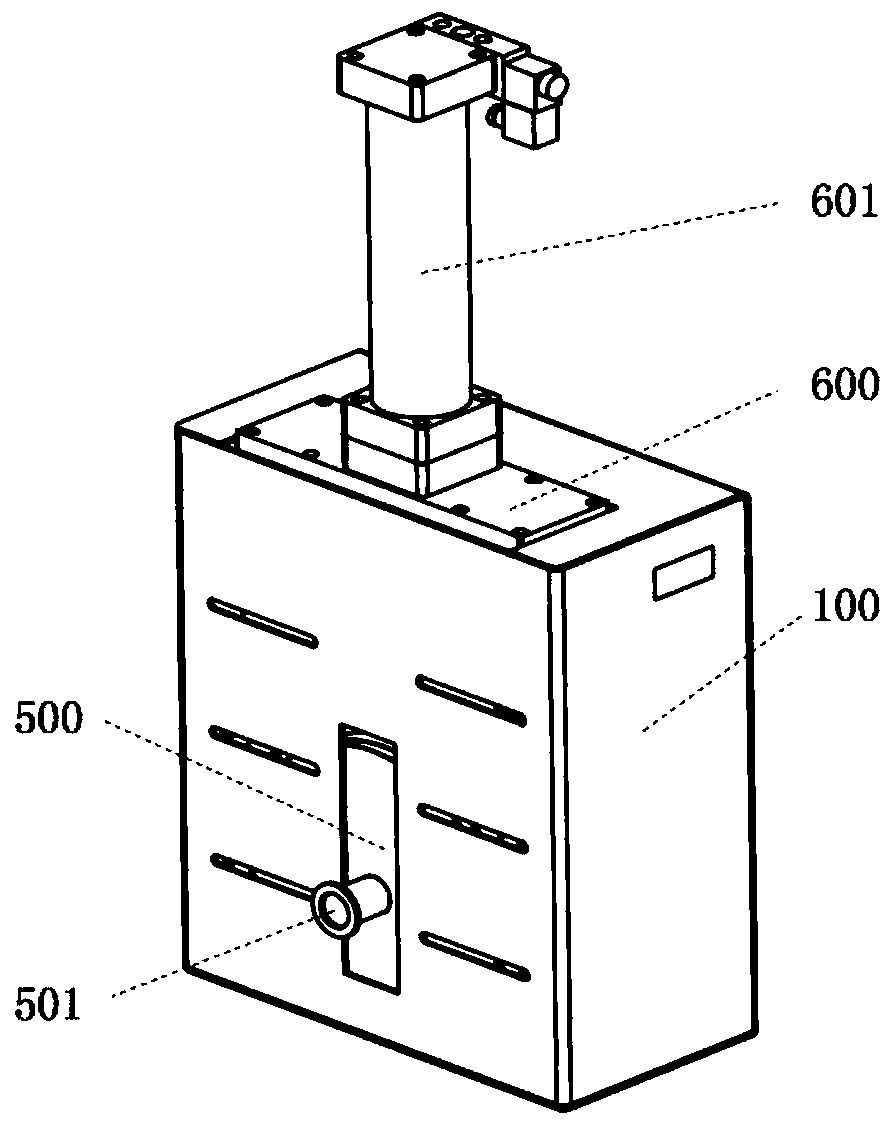

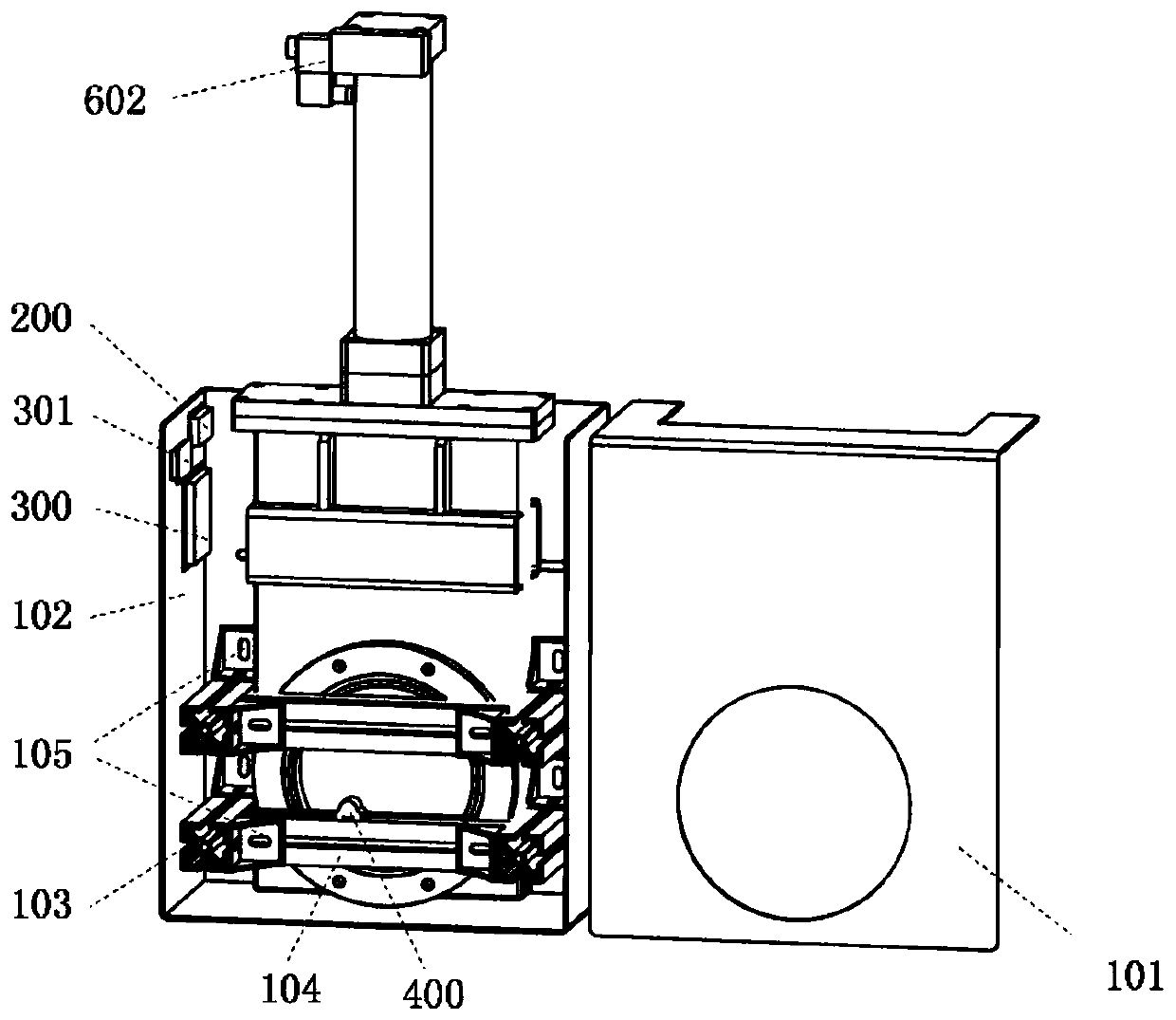

[0038] Such as Figure 1-7 As shown, according to a kind of portable vacuum gate valve testing system of the present invention, this embodiment is realized by the design form that all components are integrated in the portable adjustable box 100, are portable adjustable box 100, power supply 200, The cycle control component 300, the sensor component 400 and the test cover 500, the object to be tested is a pneumatic vacuum flapper valve 600, and its driving element is a pneumatic cylinder 601. The cycle control component 300 controls the vacuum by controlling the solenoid valve 602 of the pneumatic cylinder 601. The switch of the gate valve 600. The vacuum gate valve has two flanges, the sealing surface flange 603 and the base flange 604. The test cover 500 is connected to the base flange 604 . Wherein, through the flange 603 on the sealing surface, the switching status of the vacuum gate valve 600 can be observed.

[0039] Figure 1~3 The above is a schematic diagram of the...

Embodiment 2

[0046] Figure 8 It is a schematic diagram of the system composition of the second embodiment. In the second embodiment, the vacuum gate valve 600 under test adopts the form of electric drive, and the electric cylinder 601' is used as the power drive element, and the operation of the electric cylinder 601' is realized by the motor 602'. According to the portable vacuum gate valve testing system of the present invention, in this embodiment, the power supply, cycle control components and the driver of the measured object are integrated in an external control box 300', which is independent of the portable adjustable box 100', The sensor assembly 400 is installed inside the portable adjustable case 100'.

[0047] In this embodiment, the external control box 300' has the functions of timing, counting and alarming, and controls the stroke and test of the electric cylinder through the motor control signal sent out at regular intervals, and then drives the motor 602' to control the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com